Reports: ND1052588-ND10: Elucidating Competing Transport and Kinetic Mechanisms for Understanding Material Durability of Carbon Felt Electrodes

Venkat R. Subramanian, Washington University in St. Louis

1.

OBJECTIVES:

2.

RESEARCH FINDINGS

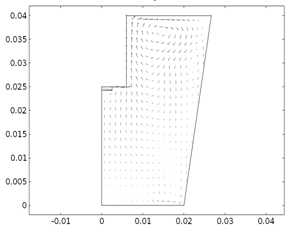

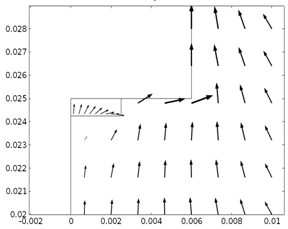

Fig. 1. (a) Arrow plot for

the velocity field in the 2D Porous RDE in both porous electrode and bulk

electrolyte domain at 12,000 rpm (b) Inset of velocity field in the porous felt

region and its vicinity.

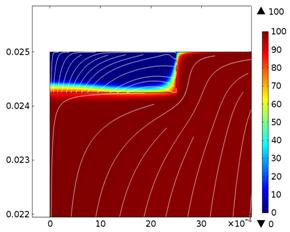

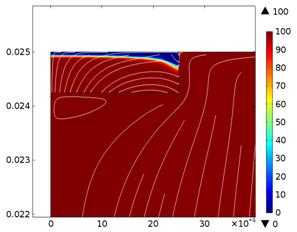

Fig. 2. Spatial variation

of V 3+ species concentration (mol/m3) for low and high rotation

rates with 0.75 mm thick porous felt (A. 634 rpm & B. 3791 rpm)

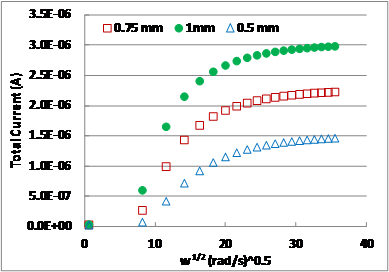

Fig. 3.Variation of total

current in the disk with rotation speed (rpm) as a function of film thickness. 3.

OUTCOMES

4.

FUTURE RESEARCH

2.

T. Nguyen, R.

Savinell, Flow Batteries, in: The Electrochemical Society Interface, vol. 19,

The Electrochemical Society, New Jersey, USA, Fall 2010, pp. 54-56.

![]()