Reports: ND1052907-ND10: Large 'Molecular Panel' Based Metal-Organic Architectures for Gas Storage and Catalysis

Gellert Mezei, PhD, Western Michigan University

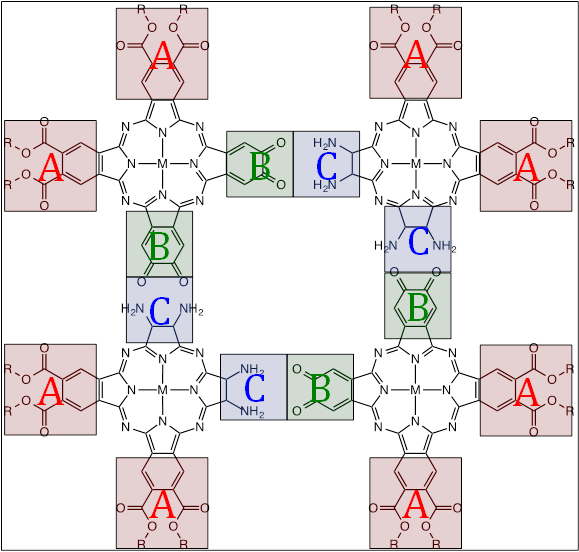

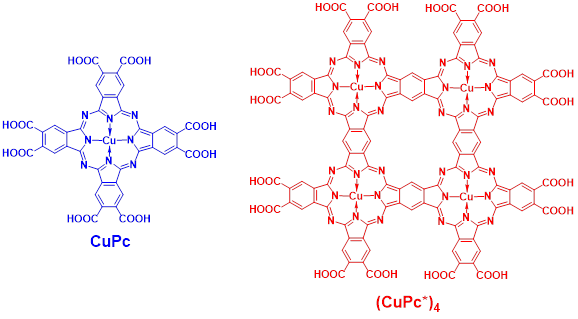

Figure 1. Structures of monomeric phthalocyanine octacarboxylic acid

CuPc and cyclic tetrameric phthalocyanine hexadecacarboxylic acid (CuPc*)4.

1.

Tetrakis-(N-((4-carboxy)phenyl)phthalimide) copper phthalocyanine

2.

Tetrakis-(N-((4-ethoxycarboxy)phenyl)phthalimide) copper phthalocyanine

3.

Tetrakis-(N-((3,5-dicarboxy)phenyl)phthalimide) copper phthalocyanine

4.

Tetrakis-(N-(4-pyridyl)phthalimide) copper chthalocyanine

5.

Tetrakis-(N-(p-tolyl)phthalimide) copper phthalocyanine

6.

Tetrakis-(N-(pyrazole-4-yl)phthalimide) copper phthalocyanine

7.

Tetrakis-(N-(anthracene-2-yl)phthalimide) copper phthalocyanine

8.

Tetrakis-(N-(pyrene-1-yl)phthalimide) copper phthalocyanine

9.

Tetrakis-(N-(4-(trifluoromethyl)-2H-chromene-2-one-7-yl)phthalimide) copper

phthalocyanine

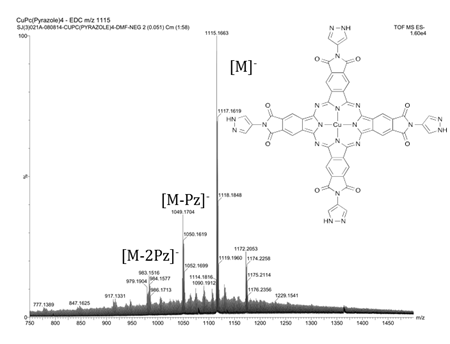

Figure 3. Electrospray

ionization mass spectrum of tetrakis-(N-(pyrazole-4-yl)phthalimide) copper

phthalocyanine.

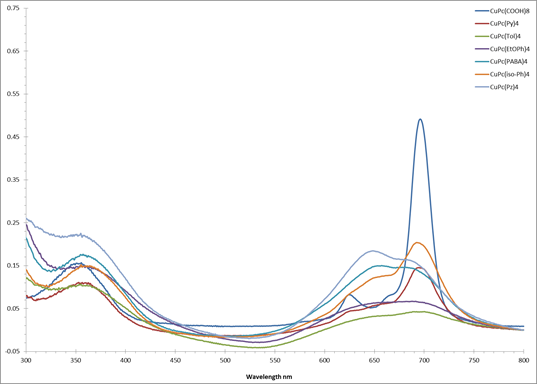

Figure 4. UV-vis spectra of variously

substituted copper phthalocyanine building blocks.

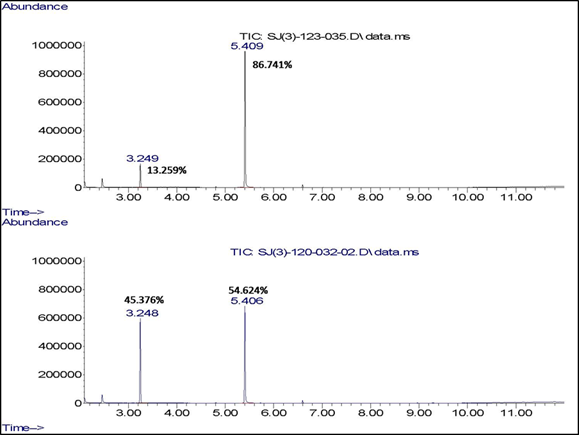

Figure 5. GC-MS analysis of

the reaction mixture obtained by the uncatalyzed (bottom) and 0.5 mol%

CuPc-catalyzed (top) oxidation of dibutylsulfide (at 3.25) to dibutylsulfoxide (at

5.41) by hydrogen peroxide after 2 hours.