Reports: DNI753294-DNI7: A Fresh Perspective on Admicellar Polymerization: Determining the Effects of Deoxygenation, Monomer Partitioning, and RAFT Polymerization on Thin Film Formation

Adam E. Smith, PhD, University of Mississippi

One of the major challenges leading to a lack of fundamental

knowledge regarding the admicellar polymerization process is the difficulty of

synthesizing enough polymer for detailed kinetic studies and the difficulty of

completely extracting the polymer from the substrate without degradation

occurring; thus the properties (i.e., molecular weight, tacticity, branching) of

polymers synthesized by admicellar polymerization are virtually unknown. A

significant effort in the first year was devoted to investigate proper

techniques for synthesizing sufficient polymer for analysis. This included

investigating both porous silicas of varying surface area and non-porous glass

beads as the substrate. In our studies, we have utilized cetyltrimethylammonium

bromide (CTAB) as the surfactant, precipitated silica (Hi-Sil 233) as the

substrate, styrene as the monomer, and either 2,2'-azoisobutyronitrile (AIBN)

or 4,4-azobis(4-cyanopentanoic acid) (V-501) as a radical initiator. We

utilized a monomer to surfactant ratio of 2:1 and varied the monomer to

initiator (M:I) from 15:1 to 1000:1. After polymerization, the formed polymer

film was isolated from the silica via Soxhlet extraction with THF.

Effect of Oxygen on Admicellar Polymerization In previous investigations, admicellar polymerizations

utilized a low monomer-to-initiator ratio relative to emulsion polymerization.

Our hypothesis is that the requirement for a high initiator concentration stems

from the presence of oxygen (a known radical inhibitor) and can be overcome by

the removal of oxygen from the polymerization solution. In order to investigate

this hypothesis, we deoxygenated the solution by purging the headspace with

nitrogen gas. Immediately prior to removing the nitrogen purge, deoxygenated

styrene was added to the solution and the reaction flask sealed. After

polymerization, the polymer modified silica was dried and analyzed by TGA to

determine the mass of the polymer film. Additionally, the polymer film was

extracted from the silica and analyzed by gel permeation chromatography.

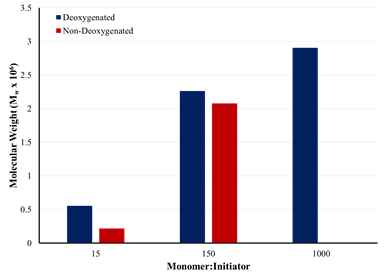

Figure 1 shows the results of preliminary studies on the

effect of deoxygenation on the molecular weight of the polymer formed by

admicellar polymerization using AIBN as the radical initiator. At M:I ratios of

15:1 and 150:1, the molecular weight of the isolated polymer formed in the

deoxygenated system is larger than that formed in the presence of oxygen. At a

M:I ratio of 1000:1, insufficient polymer was extracted from the polymerization

mixture containing oxygen for analysis. These results are thought to be due to

the termination of polymerization by oxygen diffusing into the adsorbed

bilayer. Since AIBN is water-insoluble, the initiator partitions to the

hydrophobic core of the bilayer. Once the polymerization is started, monomer adds

to the active radical until the growing polymer chain is terminated by either

another radical or a radical inhibitor such as oxygen. In the non-deoxygenated

polymerization solution, oxygen may diffuse into the adsorbed bilayer,

prematurely terminating polymerization and leading to suppressed molecular

weight as shown in Figure 1.

Figure 1. Effect of deoxygenation on the molecular weight of

polymer films formed by admicellar polymerization.

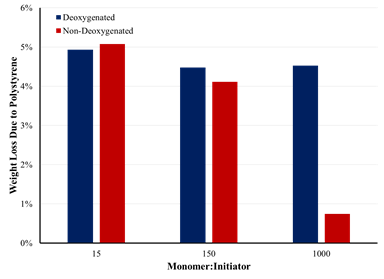

The effect of deoxygenation may also be seen by thermogravimetric

analysis (TGA) on the modified silica. Figure 2 shows the weight loss

associated with the polystyrene film formed on the surface on the silica. Based

on system loading, the weight loss expected if all styrene monomer is

incorporated into the polymer film is roughly 5%. At an M:I of 15:1, both

systems show that essentially all the styrene is incorporated into the polymer

film. At 150:1 and 1000:1, the deoxygenated system generates a greater mass of

polymer film than the polymerization performed in the presence of oxygen. The

TGA reaffirms the observation of very little polymer formed in the presence of

oxygen at an M:I ratio of 1000:1.

Figure 2. Effect of deoxygentation on polymer film mass at

varying monomer to initiator ratios.

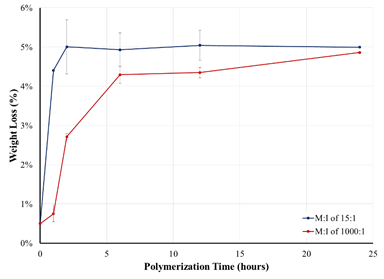

Kinetics of Admicellar Polymerization Another focus for the first year of the project has been to

investigate the kinetics of admicellar polymerization. Utilizing the same

system described above, we utilized TGA to determine the weight loss attributed

to polystyrene for M:I ratios of 15:1 and 1000:1 as a function of

polymerization time. As Figure 3 shows, polymerizations performed at a 15:1

ratio reach completion after two hours while polymerization utilizing a M:I

ratio of 1000, require between 8 and 24 hours to reach completion.

Figure 3. Kinetics of the admicellar polymerization of

styrene for M:I ratios of 15:1 and 1000:1.