Reports: DNI552279-DNI5: Rapid Prediction of Sulfide and Oxide Catalyst Surface Structures Using Insight from Density Functional Theory

Lars C. Grabow, PhD, University of Houston

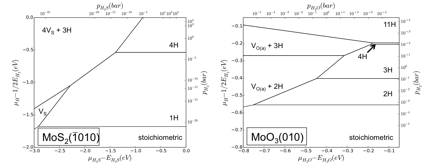

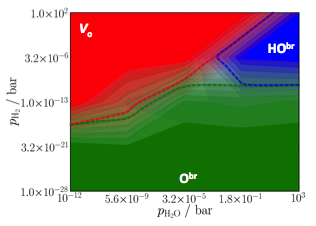

Figure 1 Surface Phase Diagram for MoS2(-1010) and MoO3(010)

under hydrotreating conditions.

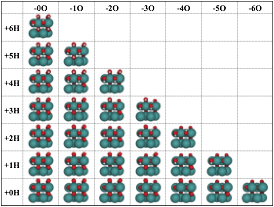

Figure 2 Grid representation of surface terminations obtained

by adding H (vertical) or creating O vacancies (horizontal) to the

stoichiometric RuO2(110) surface (bottom left).

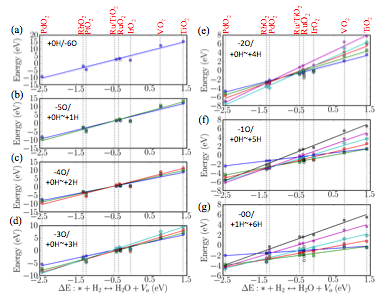

Figure 3 Linear scaling relations for rutile surface free

energies as a function of oxygen vacancy formation energy.

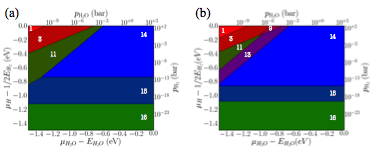

Figure 4 Comparison between the RuO2(110) phase

diagram from (a) DFT calculations, and (b) using linear scaling relations (b).

Figure 5 Kinetic phase diagram for RuO2(110)

obtained from kinetic Monte Carlo simulations.