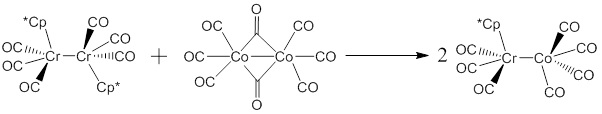

Reports: ND351756-ND3: Catalytic Carbonylation of Ketenes under Oscillating Pressures of Carbon Monoxide

Carl D. Hoff, PhD, University of Miami

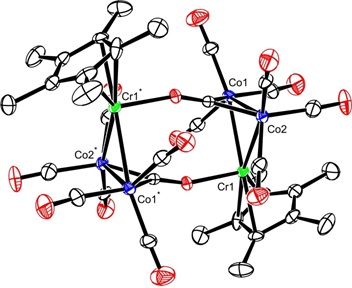

The mixed metal dimer appears to react more rapidlywith trimethylsilyl

diazomethane yielding the corresponding ketene but it is prone to decarbonylation