Reports: ND752132-ND7: Biomimetic IPNs - Harnessing the Power of Phase Interactions

LaShanda TJ Korley, Case Western Reserve University

(1) Spectroscopic examination and mechanical response of photocurable supramolecular elastomers

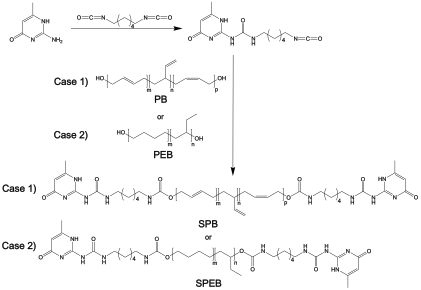

Ultraviolet (UV) irradiated supramolecular polybutadienes (PBs, 1200 and 3000 g/mol) containing 2-ureido-4-[1H]-pyrimidone (UPy) linkages were examined as a simple model for curable supramolecular elastomers (Figure 1). Control systems utilized saturated poly(ethylene-co-1-butene) (PEB) cores were also synthesized for comparison.

Figure 1. Synthetic scheme for the design of supramolecular PB elastomers.

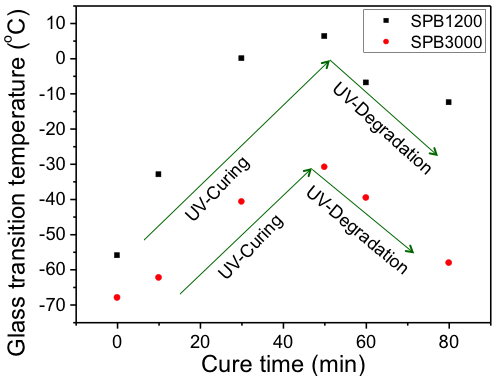

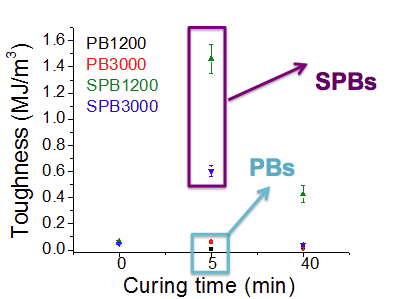

Examination of the role of UV irradiation on the curing of the PB core revealed that the UV-initiated crosslinking dominated up to ~50 min exposure time as revealed by changes in the glass transition temperature (Figure 2), spectroscopic studies, and contact angle measurements. Synergistic mechanical response was observed at 5 min-UV cure, yielding toughness enhancement up to ~200X due to the balance of UPy dynamics and PB curing during deformation (Figure 3). It was determined that the presence of UPy hydrogen-bonded aggregates accelerated the UV crosslinking process during the irradiation stage. This observation was attributed to the microphase-separated structure of UV-irradiated supramolecular elastomer, where UPy aggregation increased the probability of interaction between the pendant vinyls involved in UV-crosslinking. The molecular weight of the PB core influences overall UPy concentration, impacting mechanics and phase segregation. These fundamental studies have informed our main investigation of semi-IPNs derived from supramolecular PEB and hydroxyl-terminated PB.

Figure 2. Effect of curing time on glass transition temperature in supramolecular PB elastomers.

Figure 3. Toughness response in PB-based elastomers: SPBs and PBs

(2) Morphology, thermal behavior and mechanics in semi-IPNs using supramolecular and photocurable elastomers

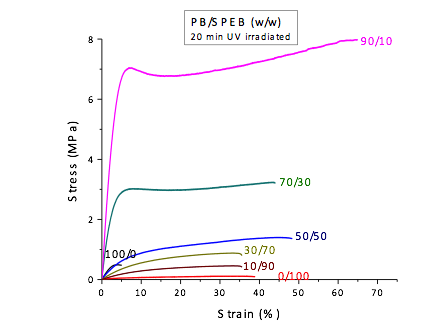

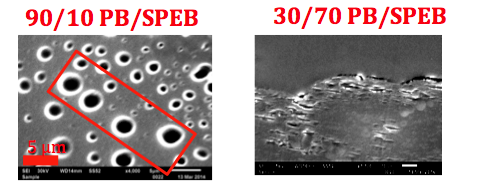

Semi-IPNs are the ideal framework to investigate concepts related to synergistic mechanics, phase dynamics, and network morphology. We fabricated the semi-IPNs via simultaneous mixing of the PB and SPEB components at weight ratios varying from 90/10 to 10/90 followed by solvent casting to form films. Irradiation via ultraviolet light was then conducted for up to 40 min. Using toughness as our mechanical target, 20 min-UV irradiation produced significant enhancement compared to controls and amo ng the PB/SPEB series. It is important to note that the degree of phase separation increased with curing time as determined by droplet size from scanning electron microscopy (SEM). Several key trends were also observed in the stress-strain response (Figure 4).

Figure 4. Stress-strain response of SPEB/PB semi-IPNs at 20-min UV irradiation

At low levels of SPEB incorporation (90/10, 70/30), yielding, significant extensibility, and high tensile strength were observed compared to when SPEB was the major phase. To understand these phenomena, we examined the blend morphology. SPEB formed droplets with a crosslinked PB matrix until 50/50 PB/SPEB at which point phase inversion occurred. Droplet size increased as well with increasing SPEB content until 50/50 composition, and then followed the opposite trend. Variations in droplet morphology (round vs. elliptical) were also noted depending upon SPEB fraction. Fracture experiments (Figure 5) highlighted that the dominated mechanism in the PB/SPEM 90/10 and 70/30 is dilatational shear banding, which contributes to energy absorption (e.g. toughness) during deformation. In contrast, crazing and cavitation is observed for the PB rich semi-IPNs.

Figure 5. Examination of the fracture behavior in SPEB/PB semi-IPNs

This behavior was attributed to distinct, overall phase incompatibility coupled with minor interphase interpenetration in semi-IPNs with SPEB as the minor phase. The interphase region drives the yielding behavior in the 90/10, 70/30 SPEB/PB systems, suggesting a delicate balance between organization and interactions. It is assumed that the hydrogen-bonding character of the PB component is responsible for this interphase behavior. Future studies are in progress, which probe the effect of the PB end-group on assembly and interphase region.

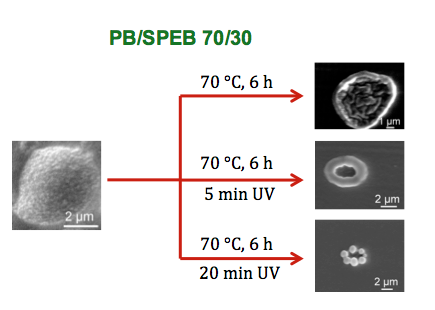

(3) Assembly behavior of semi-IPNs as a function of UV irradiation and temperature

One of the most promising aspects of this work is the self-assembly observed in these non-reactive immiscible polymer blends. We can tune the degree of irradiation or crosslinking in the PB phase and the dynamic nature (e.g. temperature) of the SPEB phase independently to transition from macro to nanophase separated structures (Figure 6). For example, in the 20 min-UV irradiated 70/30 PB/SPEB semi-IPNs, a micron-size, SPEB micron-size spherical phase was observed at 70 °C, which is above the UPy dissociation temperature. Irradiation of the PB phase for 5 min after 6 hrs heating at 70 °C resulted in a shift to hollow micron-size SPEB spheres. Increasing the irradiation time to 20 min produced hollow micron-sized structures with nanospheres decorating the perimeter. It is proposed the UPy motifs and the hydroxyl end groups mediate interfacial interactions crucial to this assembly, while phase separation is modulated by incompatibility between PB and SPEB cores. The combination of temperature and UV crosslinking are necessary for the evolution of this novel three-dimensional, nanostructure development. Kinetics of evolution and the impact of these parameters are the subject of ongoing investigation.

Figure 6. Promoted self-assembly in PB/SPEB semi-IPNs via SEM