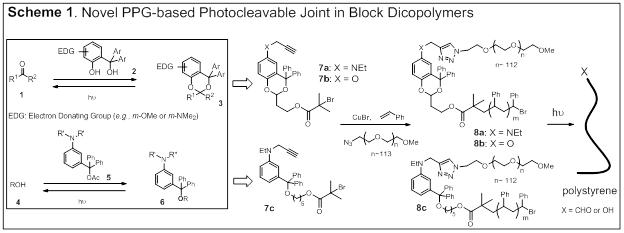

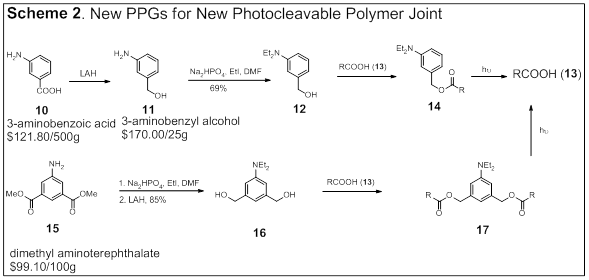

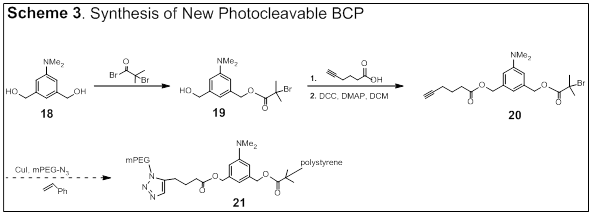

Reports: ND751827-ND7: Photolabile Protecting Group-Based New Method for the Development of Photodegradable Polymers

Pengfei Wang, University of Alabama at Birmingham

Pengfei Wang, University of Alabama at Birmingham

Copyright © American Chemical Society