57th Annual Report on Research 2012 Under Sponsorship of the ACS Petroleum Research Fund

Reports: ND751620-ND7: Polymer Single Crystals for Nanocomposite Hydrogel

Christopher Y. Li, Drexel University

Introduction:

Hydrogels are polymer networks swollen with a large amount of water. As a combination of solid and water component, hydrogels have a high permeability to small molecules and can be responsive to different types of stimuli such as pH, ionic strength, temperature, and light. During the past two decade, significantly efforts have been devoted to hydrogel study for applications such as tissue engineering, drug delivery, and sensing. However, one intrinsic drawback for conventional hydrogel is that they are mechanically weak; typically fail at a tensile stress less than one MPa and stain less than 100%. This significantly limit the application of hydrogel in tissue engineering because many load-bearing biological soft tissues are much stronger and present excellent mechanical performance with high toughness, shock absorbing, low sliding friction and robust contraction. It is generally agreed that the relative high water contents and heterogeneous structure are the two key reasons for the poor mechanical behavior of hydrogel. To this end, a number of strategies have been proposed to achieve good mechanical performance, including topological (TP) gel, double network (DN) gel and nanocomposites (NC) gel. One significant progress in searching strong hydrogel is the development of NC hydrogel. Nanoclay was used as a micro-crosslinking agent. The resultant gels are strong and transparent.

Although falling into the ideal length scale of nanosciences, polymer single crystals (PSCs) have never been considered as "nanomaterials". PSCs are always used as model morphology of otherwise polydispersed semicrystalline structures. However, comparing PSC with previous mentioned NC hydrogel, one can immediately notice that PSCs have similar morphology as nanoclay does. For 2D PSCs, the thickness of the lamellae is a few nanometers and the lateral size ranges from a few nanometers to a few hundred micrometers, which can be readily tuned. This unique dimension suggests that PSCs can be used as nanofillers for composite materials design. In the proposed research, we aim to demonstrate that PSC hydrogels can be formed with excellent mechanical properties. Polycaprolactone (PCL) is chosen as the model polymer to form PSC because 1) it is biocompatible and biodegradable, hence the synthesized hydrogels can be used for biomedical applications; 2) uniform PCL lamellar crystal can be readily achieved; 3) a variety of end functional groups can be readily introduced to PCL PSC surface, which can be used to immobilize nanoparticles to further enhance mechanical properties.

Results and discussions:

In the first year of the project, we have successfully synthesized end-functionalized PCL, fabricated PCL PSCs with functional surface, immobilized silica nanoparticles (SiNPs) on the single crystal surface, and synthesized target hydrogel, detailed as follows.

1) Functional PCL synthesis: In order to attach SiNPs on to polymer single crystal surfaces, telechelic PCL with a, ¦Ø PCL-diol was used to couple with 3-isocyanatopropyl triethoxysilane to obtain functionalize PCL-disilane. Excessive 3-isocyanatopropyl triethoxysilane (20:1 molar ratio) was used in the reaction to ensure the PCL-diol was fully reacted. NMR was used to characterize the silane functionalized PCL.

2) Functional PCL PSC growth: PCL single crystal was grown using a self-seeding method. In brief, PCL solution was seeded at 43°C for 10min and followed by crystallization at room temperature for overnight. The resultant PCL single crystals were observed under optical microscopy using a phase contrast mode. The PCL single crystal had a hexagonal shape. The thickness of the PCL single crystal was determined using atomic force microscopy and the results suggest an extended chain PSC. Therefore, all the silane groups are excluded onto the PSC surface.

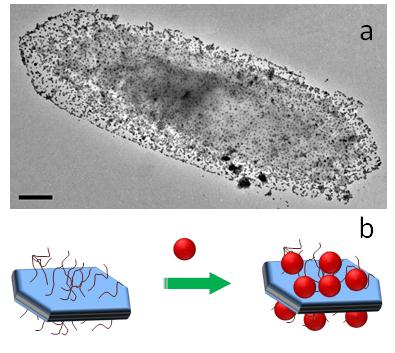

3) SiNP immobilization: Spherical SiNPs dispersed in isopropanol solution was used to fabricate the PCL-silica hybris. Two types of SiNPs with sizes of 15nm and 50nm were immobilized on the PCL single crystal surface. The particle size distribution of SiNPs was determined from TEM images with Image J software from 100 particles. 15nm SiNPs had the sizes range from 6.9 to 19.2nm with an average particle size of 13.1+/- 2.8nm. 50 nm SiNPs range from 29.0 to 72.8nm with an average sizes of 46.6+/- 8.4nm. The size distribution for 50nm SiNPs had a broader particles sizes distribution compared to 15nm SiNPs due to the commercial manufacturing process. Figure 1 shows SiNP-decorated PCL PSC.

Figure 1. (a) TEM image of SiNP-decorated PCL single crystals. (b) schematic representation shows a surface-functionalized polymer single crystal can immobilize nanoparticle onto its surface.

4) Hybrid hydrogel synthesis, Polyacryamide (PAAM) hydrogel containing previous discussed PCL-SiNP hybrid were synthesized through in-situ free radical polymerization. AAM monomer, BIS crosslinker, TEMED catalyst, APS initiator and water content were fixed in all the hydrogel samples. Reaction solutions with various filler contents (5-15 wt.%) were purged under nitrogen to remove oxygen, which would inhibit the polymerization. The reaction solution was subject to vortex mixing and sonication to ensure the filler uniformly dispersed in the matrix.

Summary:

In the first year of the project, we have successfully synthesized targeted functional polymers, fabricated SiNP-decorated PCL PSC, and synthesized a series of hybrid hydrogels. In the second year of this project, we will systematically investigate the mechanical properties of these hydrogel materials and establish the structure-property relationship.