57th Annual Report on Research 2012 Under Sponsorship of the ACS Petroleum Research Fund

Reports: DNI550429-DNI5: Fundamental Insight into the Hierarchical Engineering of Nanoparticulate and Templated Porous Films for Molecular Separations

Mark A. Snyder, PhD, Lehigh University

A facile hard-templating method has been developed to prepare porous carbon films with control over 1) film thickness spanning the nanometer to tens of nanometer range, 2) mesopore size, topology, and coordination, and 3) microporous-mesoporous morphology. These strategies aim to address challenges associated with the current paradigm for inorganic films, of 1) permeabilities that fall short of industrial needs, and 2) pore size and coordination/orientation that is poorly controlled. Development of a versatile porous thin film templating strategy should enable realization of a wide range of applications spanning membrane separations to high-efficiency electrode technologies.

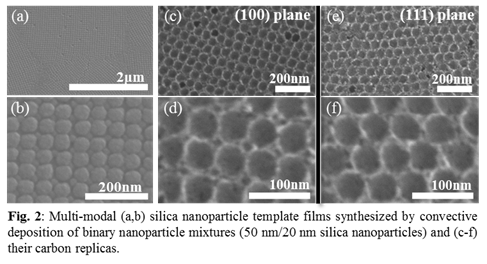

Leveraging a versatile ordered mesoporous silica for templating tunable carbon films We have leveraged fine control over monosized silica nanoparticles (i.e., 5 to tens of nanometers) and their facile convective assembly into ordered mesoporous silica films for realizing hard templates suitable for synthesizing robust carbon replica films of tunable thickness and tailored pore structure (micro-mesoporous) (Figure 1) and topology (multi-modal) (Figure 2). Recent work has focused on fundamental and technological development spanning: 1) realization of multimodal template films by facile assembly techniques (Figure 2), 2) film processing and transfer among substrates, 3) versatility of decoupled templating strategies for addressing a range of carbon (and other) sources, and 4) adaptation of hard-templating to a 'one-pot' process.

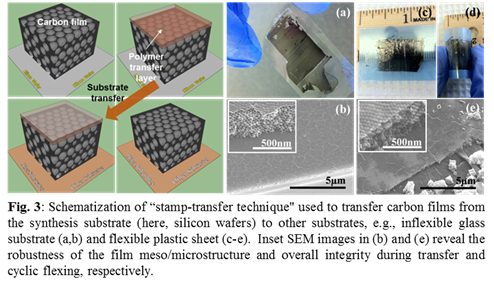

Flexibility and transferability of 3DOm carbon films Film transfer from synthesis to application substrates is important in cases where temperature instability of the application substrate exists. We have adapted recently reported polymer transfer strategies to establish a stamp-transfer technique that enables detachment and transfer of carbon films from silicon wafers to desired substrates. This approach involves the use of a sacrificial PDMS stamp, spin-coated on the carbon thin films, as a means for stabilizing the films during interfacial etching and transfer from the base silicon wafer to other substrates (Figure 3). Adherent porous carbon films on application-specific substrates result, with micro/mesostructure and film integrity robust to transfer (Figure 3b) and even cyclic bending when supported on flexible substrates (Figure 3e).

Toward high-flux mesopore-supported microporous membranes Within the arena of industrial gas separations, carbon molecular sieve (CMS) technologies show good separation of small molecules (e.g., He, N2, CO2, CH4). Among a variety of polymers, poly(furfuryl alcohol), shows specific benefits for derivation of CMS membranes, yet suffers from trans-membrane dimensions in the micron scale or larger, and thus suppressed flux. Work under this PRF-DNI reveals how microporous carbon films with tunable thickness of 10-100 nm can be successfully realized atop 3DOm carbon supports (Figure 1). Transfer of defect-free 3DOm-supported, ultra-thin microporous films to porous stainless steel substrates (Figure 4) has been accomplished. Continuing work under this grant is exploring the mechanical robustness of these films as well as their capabilities for high-selectivity, high-flux molecular separations (e.g., CO2/CH4) based on their unprecedented microporous film dimensions.

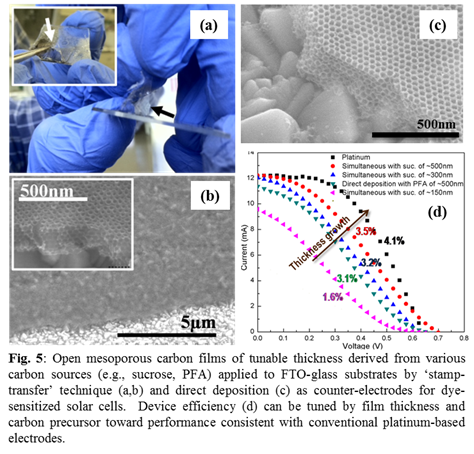

Toward efficient, cost-effective electrode materials Beyond membrane separations, the high surface area and tunable properties of the 3DOm carbon thin films (Figure 1e) offer possibilities for applications as alternative low-cost electrode materials to costly and chemically susceptible Pt-based counter-electrodes currently used in dye-sensitized solar cells (DSSCs). Through systematic study of film thickness and deposition type (adhesion), we have begun elucidating structure-property relations and demonstrated how such 3DOm carbon films, especially when deposited directly on the conductive FTO-glass substrate (Figure 5), can result in device efficiencies approaching those of Pt substrates. Continuing work under this grant is exploring how graphitic content, identified in these films, can be tuned to bolster conductivity, and, thereby enhance DSSC performance.

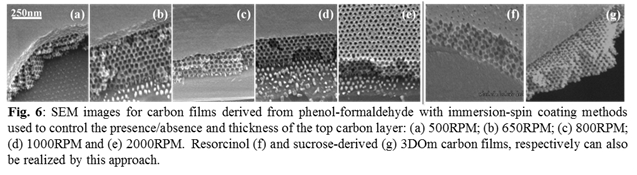

Accommodating versatile carbon precursors: An additional property handle The alternative to the technology developed under this grant is the 'soft'-templating approach that is limited to amphiphilic surfactants and block-co-polymers as templates and only a few carbon sources for replication. The decoupling of template assembly and carbon film formation offered by the hard-templating strategy enables replication by a wide range carbon sources beyond FA/OA, thus establishing its material, and, thus application, versatility. As shown in Figure 6a-e, using phenol-formaldehyde as an example carbon source, the thickness of the microporous carbon top layer on the final 3DOm carbon replica film can be easily controlled. Similar control over mesostructure and film morphology is achievable in the case of FA/OA, resorcinol-formaldehyde, and sucrose/sulfuric acid solutions, via the immersion-spin coating method as shown for the latter two cases in Figures 6fg. The breadth of this (non-exhaustive) list of viable precursors underscores the versatility of the hard-templating approach developed herein within the CMS arena for low cost alternatives to common polyimid CMS precursors, such as phenol and resorcinol resins and bio-renewable sucrose, glucose, and fructose.

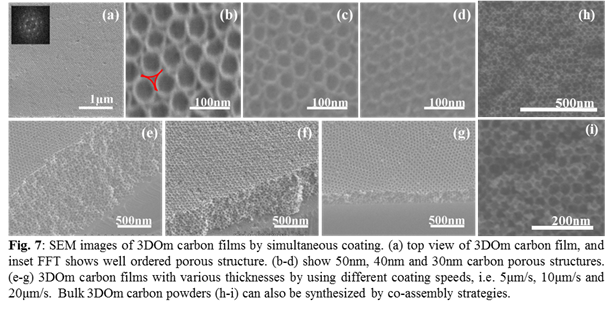

Toward a 'one-pot' hard templating of ordered bulk and thin-film carbons The inherent 'multi-step' nature of the hard templating approach is persistently cited as a critical drawback. In lieu of expensive amphiphilic surfactant or block-co-polymers employed as templates in 'one-pot- 'soft'-templating strategies, we employ monosized silica particles as effective "template molecules." Therefore, co-assembly of such silica "template molecules" with the replicating material into ordered porous structures requiring only template etching, could revolutionize the concept of hard-templating. Here, we have demonstrated how carbon sources such as sucrose and glucose can be simultaneous assembled with dispersed template nanoparticles into either bulk powders by drying or tunable thin films by convective deposition (Figure 7). In the case of the thin films, smaller, secondary mesopores (outlined in red in Figure 7b) can be observed. Ongoing work is focused on better understanding the mechanism of formation, and thereby controllability, of the hierarchical and mono-modal pore structure.

Impact We believe that this templating strategy employing cheap and easily assembled silica nanoparticles represents a versatile approach to realizing films of a wide range of compositions. Support through this ACS-PRF grant has provided the resources to catalyze and develop a growing research area for the PI, and has proven critical for generating new insights and preliminary data for proposals of an expanded scope. The grant has supported two doctoral researchers and has provided the infrastructure for carrying out related research with one undergraduate.