57th Annual Report on Research 2012 Under Sponsorship of the ACS Petroleum Research Fund

Reports: DNI949744-DNI9: Effect of Polymer and Polymer Gel on Disproportionate Permeability Reduction to Gas and Water for Tight Gas

Baojun Bai, PhD, Missouri University of Science and Technology

Background

Excess water production is one of the most prevalent operational problems facing gas companies. Polymers and polymer gels have been widely used to control excess water production in conventional hydrocarbon production assets. Water/oil or water/gas flows in porous media are strongly modified in the presence of polymers or polymer gels on the pore. So the polymers or polymer gels are often called relative permeability modifier (RPM). However, previous experiments on RPM were mostly focused on conventional rocks without fractures. The conduits for fluid flow in tight and shale gas reservoirs are primarily the natural fractures which have high permeability but low porosity. However, there is no published literature to report to what extent that polymer can reduce water permeability more than to gas permeability in fractured flow path.

Objectives

The overall objective of this project is to advance the fundamental science and the in-depth understanding of disproportionate permeability reduction mechanisms of polymer to gas and water in tight gas. Using this knowledge, we can design new relative permeability reduction agents that will lead to maximize the disproportionate permeability reduction (DPR) effect of relative permeability modifier (RPM) to gas and water in gas shales during gas production. Applications from these study results would provide information towards the implementation of the novel concepts on RPM as well as improve results of mitigating excess water production from tight gas and shale gas reservoirs.

Experiment Setup

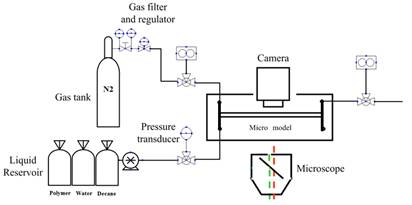

Fused-silica square capillary was developed to function as sample fracture for monitoring fluid flow behavior; the capillary was equipped with holder and tubing which was designed to fit the microscope stage. 20 cm long fused-silica, square capillaries (Polymicro, 53-μm i.d., 374-μm o.d.) were used for all experiments with 1 cm window cleared in the middle. All images were captured by a reverse microscope (Olympus, IX-51) and high-speed ICCD camera. Alexa 488 (100ppm, Microprobe) serves as fluorescence dye in the liquid phase. The experimental setup for this study is shown in Figure 1. TFE tubing was connected to the capillary, and the other end of the tubing was connected to stainless steel tubings to facilitate linking to the polymer (1000 ppm, Flopaam 3230s, SNF) and water reservoirs. High purity nitrogen gas was used as target gas phase. High accuracy regulator was used to control gas injection pressure while three gas mass flow meters (Omega Engineering) with different ranges were applied to measure the gas flow rate.

Figure 1. Experimental Setup

Experiment Results

1. Polymer Adsorption

Polymers are known to adsorb irreversibly on minerals. Figure 2 shows the microscope images of square capillary before and after polymer injection. Polymer adsorption is found to be the dominant polymer retention mechanism causing DPR effect. Polymer layers restrict the water flow after the polymer treatment and the thickness of the polymer layer is depending on the injection rate or pressure and it has an influence on the permeability reduction of various fluids. Figure 3 shows the thickness of adsorbed polymer layer at various water injection rates.

Figure 2. Microscope Images of Fused-Silica Square Capillary

Figure 3. Polymer Residual Layer Thickness at Different Injection Rates

2. Permeability Reduction

The resulting permeability reduction to water due to polymer adsorption was estimated by:

where DPwb and DPwa are the pressure drop in the capillary obtained at the same water injection flow rate before and after polymer adsorption respectively.

Figure 4 shows the results on permeability reduction to water in capillary tubes. The permeability reduction is decreasing with the increase of water injection rates. It's consistent with the trend in the thickness of adsorbed polymer layer at various water injection rates. Thicker polymer layer will reduce the pore throat size and limit the water flow which can cause the permeability reduction.

Figure 4. Permeability Reductions to Water at Various injection Rates

Gas injection before and after polymer treatment was performed to evaluate the gas permeability changes. Klinkenberg effects were used to evaluate the gas intrinsic permeability in the capillary at low mean pressure.

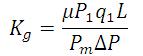

Gas apparent permeability can be calculated by using Darcy's law assuming the gas is ideal and temperature is constant:

where P1 and q1 are the gas pressure and volume flow rate at the capillary inlet, Pm and DP are the mean pressure and pressure drop in the capillary respectively given by:

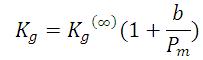

where P2 is the gas pressure at the capillary outlet. Due to Klinkenberg effects, Kg depends on gas pressure and can be expressed as:

while Kg∞

![]() is the gas intrinsic permeability

and b is the Klinkenberg constant. By plotting the

calculated apparent gas permeability on different reciprocal value of gas mean

pressure, we can determine the intrinsic gas permeability of the capillary tube

before and after the polymer treatment.

is the gas intrinsic permeability

and b is the Klinkenberg constant. By plotting the

calculated apparent gas permeability on different reciprocal value of gas mean

pressure, we can determine the intrinsic gas permeability of the capillary tube

before and after the polymer treatment.

Figure 5 shows the apparent gas permeability results before and after the polymer injection. We didn't find obvious changes (difference is less than 4%) in gas intrinsic permeability due to the adsorbed polymer layer.

Figure 5. Permeability Reductions to Gas at Various Injection Pressure using Klinkenberg Effect Plot

Results on permeability reduction to water and gas in capillary tubes illustrate and confirm the DPR effect of polymer for gas/water flow. Reduction of water permeability varies from 1.5 to 3.2 depending on different injection rates and is always larger than gas permeability reduction which remains close to 1. It means the relative permeability modifier could significantly reduce the water permeability without changing the gas flow in the micro channels. But we still need to further investigate this mechanism using tight gas and shale rocks with fractures.

Future Work

1. Test the extent to which typical relative permeability modifiers (RPM) reduce water permeability more than gas permeability using tight gas and shale rocks with fractures using the core-flooding apparatus and compare the core-flooding results with the current capillary model results.

2. Study the effect of wettability changes on the DPR to gas and water using micro models and tight gas rocks.