57th Annual Report on Research 2012 Under Sponsorship of the ACS Petroleum Research Fund

Reports: AC747951-AC7: Replacing Polyvinyl Chloride with Novel Thermoplastics Derived from Natural Gas

Stephen A. Miller, University of Florida

The primary research objective of this proposal is to synthesize novel polyoxymethylene copolymers—derived from natural gas feedstocks—having thermomechanical properties suitable for replacing the common thermoplastic polyvinyl chloride (PVC). The main significance of these research endeavors is linked to the growing recognition that PVC is environmentally problematic during all stages of its chemical lifecycle. The synthesis and identification of functional PVC substitutes will positively impact the polymer industry. Polyoxymethylene (POM) is already a commercial material with many excellent properties, but complex copolymers based on POM are rare and poorly understood. The organic feedstock for POM is methanol, which currently is derived from natural gas, a fossil fuel with a projected availability longer than that of petroleum

We have performed a number of enlightening computational studies. The ability of an alkyl branch to depress the melting temperature in a polyoxymethylene chain is measurably less than that in a polyethylene chain. The factors that inhibit the alkyl-branch plasticization of polyoxymethylene were considered by computational assessment of a series of model compounds at various levels of theory: DFT B3LYP 6-31+G*, DFT B3LYP 6-311++G**, MP2 cc-pVTZ, T1, and G3(MP2).

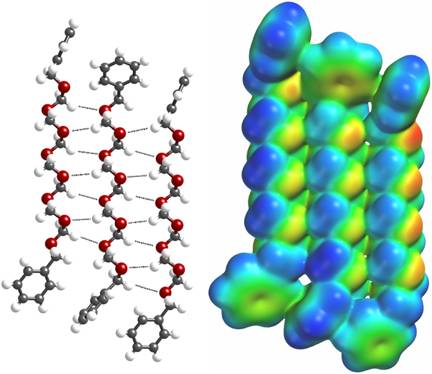

An important model for the polyoxymethylene chain can be found in 1,17-diphenyl-2,4,6,8,10,12,14,16-octaoxaheptadecane (Ph(CH2O)8CH2Ph), which contains eight oxymethylene units and has previously been structurally characterized by X-ray crystallography (J. W. Bats, C. Miculka, C. R. Noe, Acta Cryst. 2007, C63, o190-o192). We have analyzed the packing structure of this compound in search of intermolecular chain-chain interactions. Consider the lattice plane depicted in Figure 1. These chains, indeed, appear to have significant interaction between the delta+ of the acetal hydrogens and the delta– of the oxygens. The electrostatic potential map reveals significant electron density between the chains. Intramolecular interactions—characterized as acetal CH...O hydrogen bonds—are surprisingly strong and likely encourage conformational regularity in the vicinity of the alkyl branches, allowing maintenance of the intermolecular chain-chain interactions. These interactions explain the known all-gauche conformation of polyoxymethylene.

Figure 1

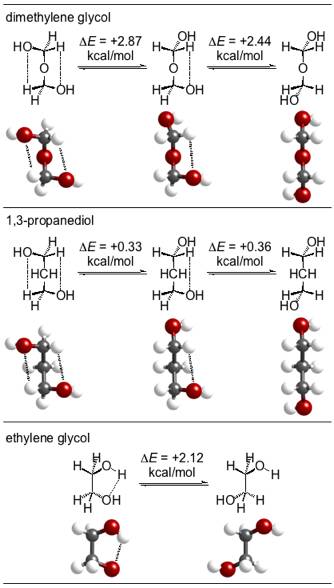

The intramolecular interactions were modeled computationally with more tractable small molecules. The acetal CH...O hydrogen bonds in dimethylene glycol average to 2.65 kcal/mol while the non-acetal CH...O interactions in 1,3-propanediol are much weaker with an average of 0.34 kcal/mol (G3(MP2)). The related, classical OH...O hydrogen bond in ethylene glycol is found to be worth 2.12 kcal/mol (Figure 2). To describe this energetic ordering, an additional stabilizing anomeric effect is invoked for dimethylene glycol, a model for polyoxymethylene.

Figure 2

The strong inter- and intramolecular forces suggest that significantly plasticized polyoxymethylene copolymers will require rather high comonomer compositions. For this and other reasons we continue our pursuit of more effective and economical approaches to polyoxymethylene plasticization.

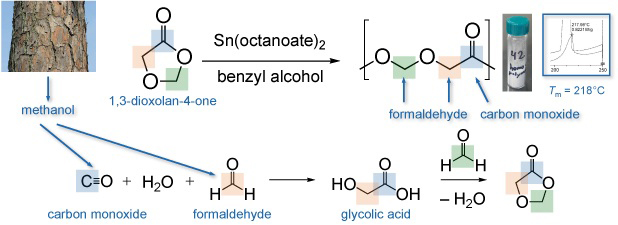

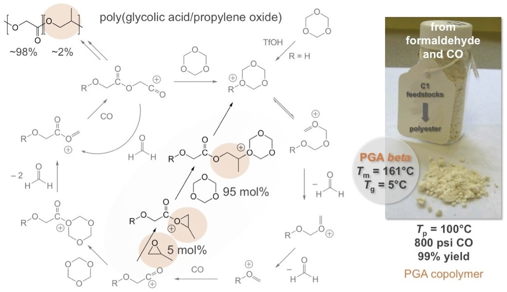

Figure 3 depicts strategy that exploits C1 feedstocks and achieves a greater effective comonomer content in polyoxymethylene chains. The synthesis of 1,3-dioxolan-4-one is achieved by the condensation of glycolic acid with formaldehyde. Since glycolic acid can be obtained via the carbonylation of formaldehyde, this 3-carbon heterocycle can be made exclusively from C1 feedstocks. Upon ring-opening polymerization, the obtained polymer is a regioregular polyesteracetal, which contains a novel juxtaposition of functional groups in polymer chemistry. Poly(1,3-dioxolane-4-one) is, fundamentally, the regular copolymer made from two parts formaldehyde and one part carbon monoxide. This is a new, semicrystalline thermoplastic that has a melting temperature near 218 degrees C. The monomer 1,3-dioxolane-4-one can also be copolymerized with a variety of lactones. This is a viable strategy for modulating the physical properties and the degradation pathways of polylactide and polycaprolactone.

Figure 3

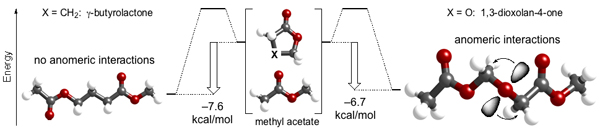

Computational studies (G3(MP2)) imply that the ring-strain of this five-membered 1,3-dioxolane-4-one (deltaH = –6.7 kcal/lmol) is similar to that of gamma-butyrolactone (deltaH = –7.6 kcal/mol), which has unfavorable ring-opening polymerization thermodynamics (Figure 4). Nonetheless, opening of 1,3-dioxolan-4-one engages two specific anomeric interactions with oxygen lone pair donations into the sigma* of an adjacent C–O bond (worth 2.8 kcal/mol) and an adjacent C–C(O) bond (worth 1.5 kcal/mol). These presumably restrict polymer conformations, contribute to crystallization polymerization, and allow for overall favorable polymerization thermodynamics.

Figure 4

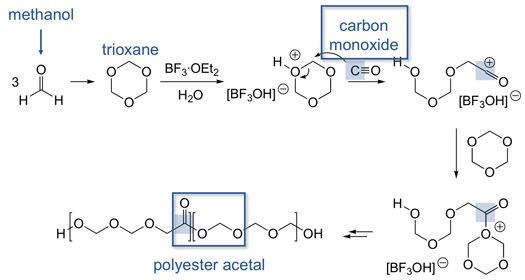

A method for modulating the properties of polyoxymethylene with a very inexpensive and practical comonomer is the cationic copolymerization of trioxane and carbon monoxide. Figure 5 depicts our strategy for this copolymerization. Reaction of the cationic chain end with carbon monoxide results in an acylium ion that can continue to react with trioxane. At that point in the polymer chain, an ester functional group will result.

Figure 5

Although carbon monoxide can be a reluctant nucleophile toward cations, high pressures of CO (800 psi) and high temperatures (100°C) have allowed significant incorporation, presumably resulting in the targeted ester functionality. Figure 6 confirms the presence of the ester functional group in the polymeric product (IR stretch at 1780 cm-1 vs no peak in the trioxane homopolymer) and we are now focused on making a series of such polymers and characterizing them fully.

Figure 6

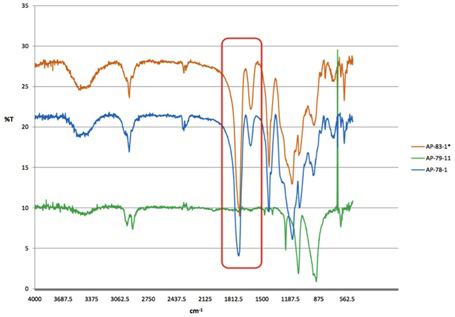

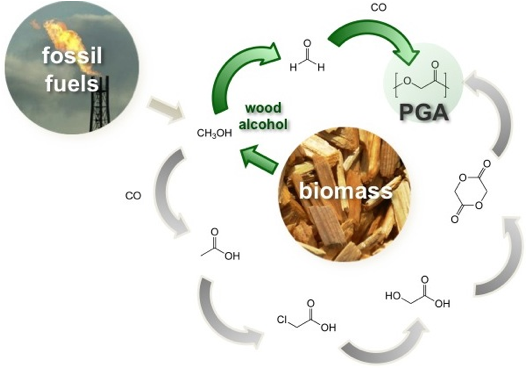

Our continued efforts to focus on C1 feedstocks have led us to novel methods for converting C1 feedstocks into a variety of polymers ideally suited for commodity thermoplastic applications. For example we can copolymerize carbon monoxide with formaldehyde to synthesize polyglycolic acid (PGA). This direct approach avoids several inefficient and wasteful steps (Figure 7).

Figure 7

This direct C1 polymerization also allows for the incorporation of other comonomers, affording tunable control over the polymeric properties. Inclusion of epoxides results in PGA/poly ether polymers with lower melting temperatures and overall thermal properties (Tm = 161°C; Tg = 5°C) similar to those of polypropylene (Figure 8). Importantly, the feedstocks employed do not require fermentation and do not compete with food sources. Moreover, the obtained PGA copolymers are readily degraded—converting to harmless glycolic acid under conditions that require only water or seawater and no enzymes, organisms, or oxygen.

Figure 8