57th Annual Report on Research 2012 Under Sponsorship of the ACS Petroleum Research Fund

Reports: UR1051438-UR10: Geometrically Cohesive Granular Materials: Experiment and Simulation

Scott Victor Franklin, Rochester Institute of Technology

We have made significant progress in the two primary goals of our project: 1) an experimental investigation into the extensional rheology of U-shaped staples and 2) developing parallelized molecular dynamics code that runs on a graphics processing unit (GPU).

Experimental Findings

Stress-strain experiments subject a cylindrical pile of U-shaped

staples (diameter d and initial length L to an axial

stress that, in the absence of deformation, increases linearly. Pile

deformations are measured to sub-millimeter accuracy, and a force

transducer that is rigidly in-line with the pile axis measures the

applied force to ~.01N. The force fluctuates; increasing as the pile

is nominally at rest and dropping sharply when the pile elongates.

Analysis code extracts the critical points in the force data and the

statistics of these events analyzed. As it is not clear that the

normalized quantities stress and strain are in fact appropriate, we

continue to report the applied force and pile elongation.

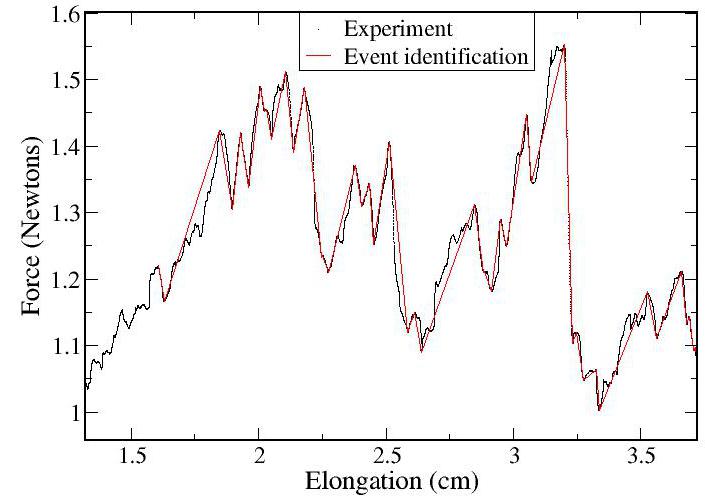

In Figure 1(left) the applied force is plotted as a function of pile

elongation. We find significant plastic "creep" --- periods where the

pile slowly grows slowly with increasing force. This contradicts the

naive interpretation of a pile that deforms only elastically until

suddenly yielding. The red line in Fig. 1(left) is a linear

interpolation between the critical points found by the analysis

software. This allows us to extract, for example, the distribution of

creep moduli (slopes of the upward lines), as shown in Fig. 1(right).

We have confirmed that the distribution of event characteristics ---

measured as either the increase in length, drop in applied force, or

yield force --- does not depend significantly on the pile history.

Specifically, the distribution after largest event is

indistinguishable from the distribution before this event.

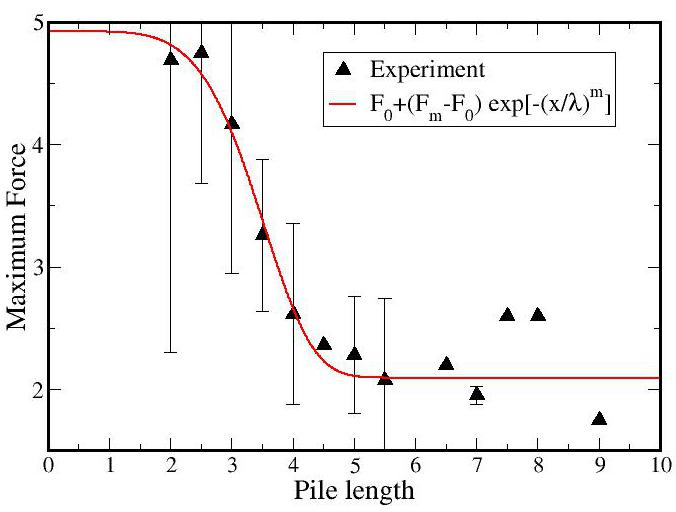

The most intriguing finding to date is that longer piles are

significantly weaker than short piles. In Figure 2(left) is plotted

the maximum force (throughout a single experiment) as a function of

the initial pile length. Short piles (<3cm) require forces of 4-5

Newtons to ultimately break, whereas longer piles (>5cm) require only

2 N. The drop appears well-fit by a stretched exponential (red line).

The underlying mechanism of the functional form, as well as the

inflection point (which is of order the pile's diameter) is unknown.

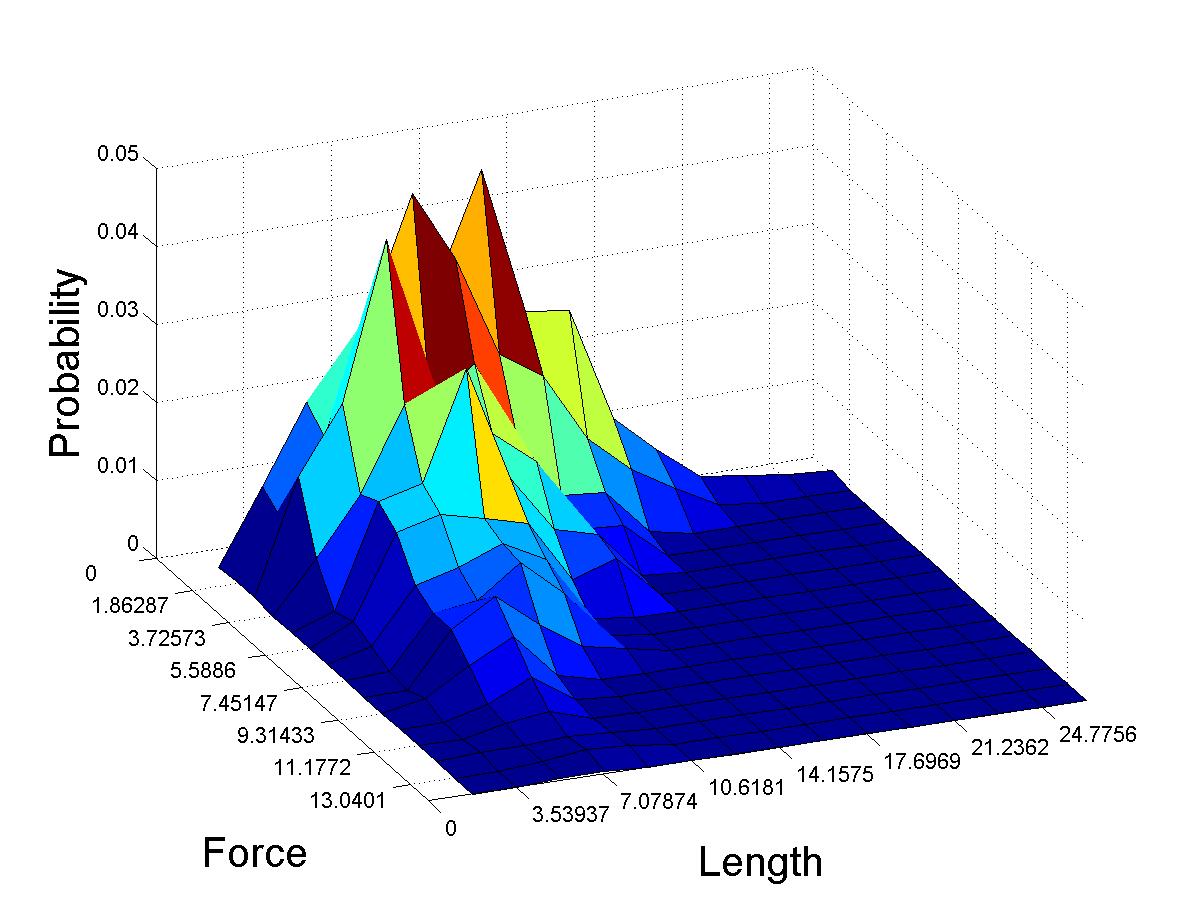

We are currently applying a weakest-link theory to the yield. This incorporates Weibull statistics, which posits that there is a fundamental lengthscale, and long piles are composed of a discrete number these sub-units. Our data indicates that the pile is not rearranging in a significant manner as it lengthens, and hence a single experiment with multiple yield point accurately samples a number of different pile lengths. By integrating the 2-dimensional probability distribution function P(F,L) (Figure 2(right)) across a given length we can predict the distribution of yield forces at specific actual length. This work is currently in progress.

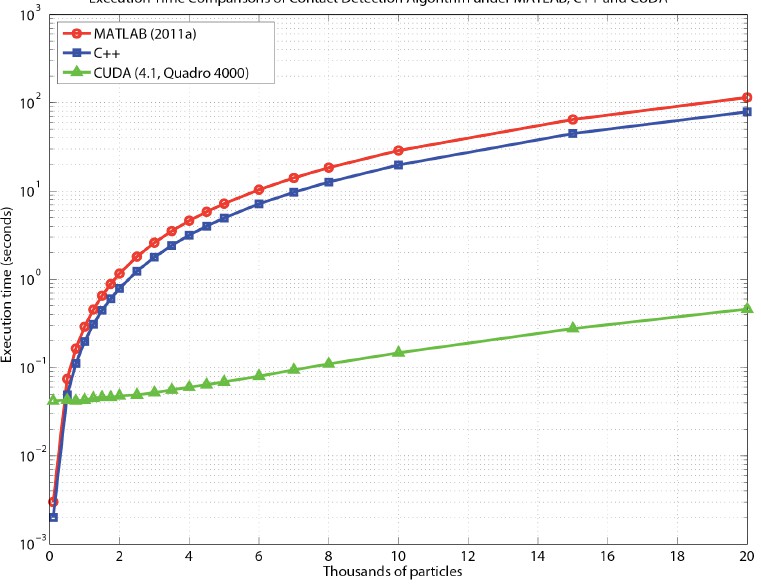

Computational Work

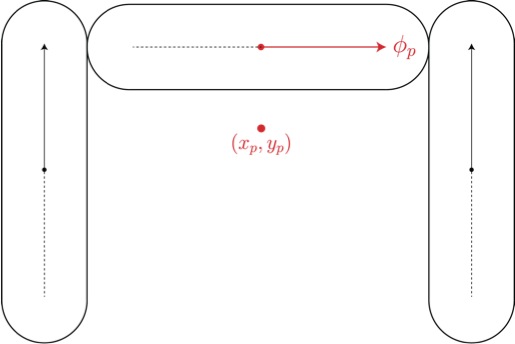

We have written 2d molecular dynamics code that simulates the shear of

"spherostaples" --- U-shaped particles composed of three

spherocylinders (Fig. 3(left)). The contact detection of

spherocylinders can be expressed analytically, and so is well-suited

for parallelization. Our current implementation is for a few thousand

particles, and so it is possible to assign each particle pair to a

separate GPU thread, enabling extremely efficient code. The scaling

of computational time with number of particles comparing Matlab, C,

and parallelized GPU code is shown in Fig. 3(right). The scale in

Fig. 3(right) is log-log; the GPU code (green triangles) is

approximately 2 orders of magnitude faster than Matlab or C code, and

makes possible 2- and 3-d simulations of these complex particles.