57th Annual Report on Research 2012 Under Sponsorship of the ACS Petroleum Research Fund

Reports: DNI750581-DNI7: Phase Separations and Morphological Evolutions of Polymer Blends under Two Dimensional Confinements

Yifu Ding, University of Colorado (Boulder)

This work seeks to elaborate the phase separation and morphological evolutions of polymer blends under 2D confinements that are beyond current knowledge of thin film polymer blends. Particularly, we aim to understand the influences of preferential wetting of constituent polymers and physical confinements on the phase diagrams and the morphological evolutions. At the first year of the project, we examined the coarsening of demixed polymer blends under the severe confinement imposed by the nanoimprint lithography (NIL), and found that the phase evolution is dictated by the preferential wetting of the components. Systematic experimental studies were conducted to understand the influence of temperature, blend composition, and film thickness [1]. A range of novel metastable morphologies were obtained as a result of the confined coarsening, as highlighted in last year's report.

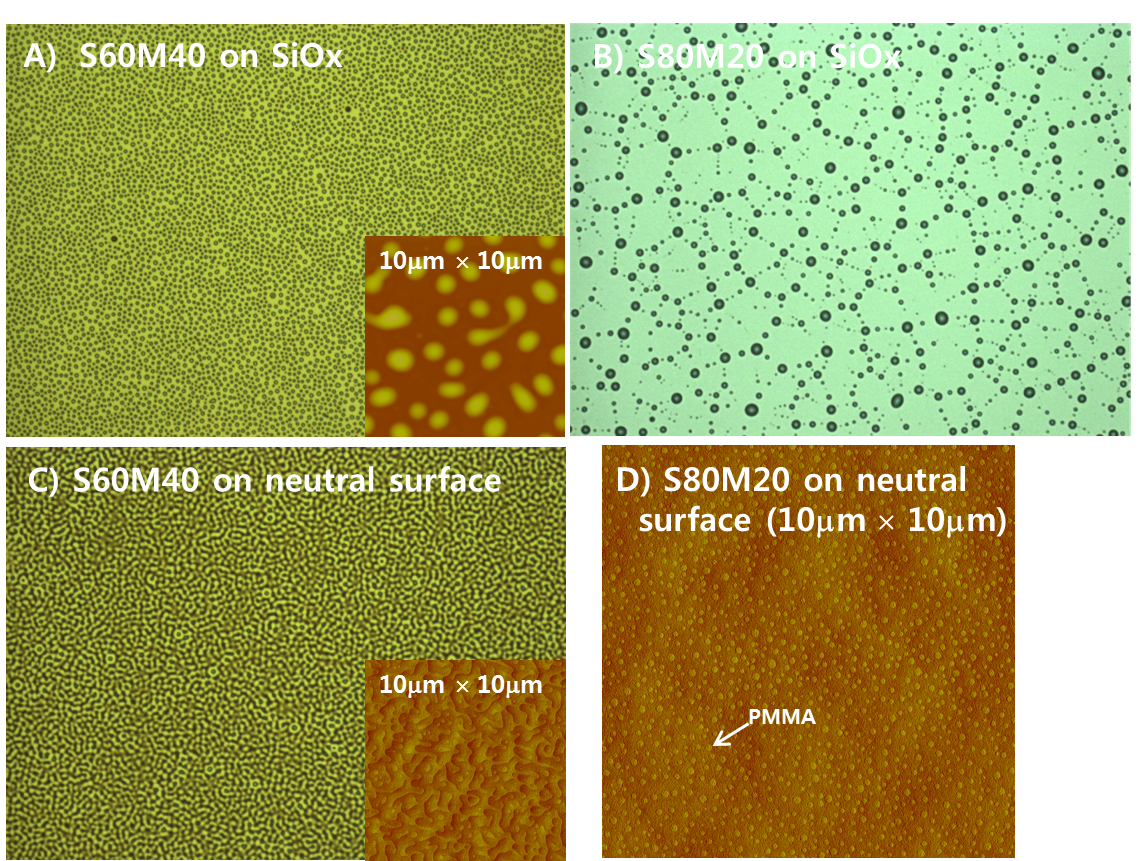

In the second year, we focus on examining the influences of pressurization and surface energy on the confined phase evolutions, particularly in comparison to that with supported films with free surfaces. First, we systematically compared the morphological evolution of thin PS/PMMA films, with varying compositions, during thermal annealing on preferential and non-preferential surfaces [2]. On native silicon oxide surfaces, the phase evolution in the films was dictated by the preferential substrate wetting of PMMA. However, the resulting PS relief structures on the PMMA wetting layer varied with the blend composition, and transitioned from capillary-fluctuation-mediated breakup to random nucleation with increased PS concentration. In particular, for PS/PMMA film with a ratio of 60/40 (referred to as S60M40) on SiOx, highly correlated PS droplets on a PMMA wetting layer formed after annealing (Fig. 1a). Such spatially correlated PS "relief" structure was resulted from the surface capillary fluctuations, in accordance with the PMMA domain coarsening and substrate wetting. Therefore, the size and correlation length of the PS droplets can be tuned by changing the PS composition. However, as PS composition increases to 80%, a bilayer (PS on PMMA) film developed quickly upon annealing, which led to the conventional random nucleation dewetting of PS films on PMMA and thus forms uncorrelated polygonal distribution of large PS droplets (Fig. 1b).

In contrast, the morphological evolution of the PS/PMMA films on non-preferential surfaces was also dictated by the coarsening of PMMA domain, but proceeded without the formation of a PMMA wetting layer (Fig. 1c and 1d). Both the PS and PMMA domains maintain direct contact with both the substrate and free surfaces throughout the evolution of the morphology. The morphologies at the interfaces were highly correlated, but with distinctive length scales. A variety of dispersed and continuous phase separated structures can thus be obtained. For example, the S60/M40 films formed bi-continuous type morphology on the neutral surface, with PS and PMMA direct contacting the substrate. As the PMMA composition dropped to 20% (S80M20), 100 nm or less PMMA cylinder domains stable within PS matrix film was obtained (Fig. 1d). Besides the different morphological paths observed on the neutral surface, the overall kinetics of the morphological evolution also significantly slowed down. Details of these can be found in the published article (ref. 2)

Fig. 1. Morphology of annealed PS/PMMA films: (a)S60/M40 and (b)S80M20 on SiOx surface, as well as (c)S60M40 and (d)S80M20 on neutral surface, respectively.

Further, we examined the influence of pressure on the phase evolution of PS/PMMA thin films. This was achieved with NIL, by using Si wafer as the confining bottom and top substrates. Specifically, we used NIL to make a sandwich film, with PS/PMMA films confined between the two Si wafer, which was then annealed under different pressure. Under vacuum oven at 170 oC, the coarsening and substrate-wetting of the PMMA domains caused the film to delaminate from the one substrate. This suggests that the Laplace pressure associated with the domain size in the blend films, can cause the film delamination from the substrate. As a result, a PS relief structure on PMMA wetting layer, identical to that annealed in free surface (Fig. 1a) was obtained. In contrast, when the sandwiched film was annealed under a 3 MPa pressure, no film delamination was observed, instead, slow coarsening of PMMA domains were observed. However, the domain coarsening is drastically different from the substrate wetting observed in Fig. 1a. Particularly, the PMMA domains grew with increasing length-to-width ratio, i.e. coarsen back into a continuous phase with increasing annealing time. Such a disperse to continuous phase is unique to the blend films under rigid confinement, suggesting that the pressurization can overcome the wetting tendency and balance the Laplace pressure of the non-circular domain shape. These results are currently being prepared for submission for publication.

1. Zhen Wang, Dae Up Ahn, and Yifu Ding, "Topographically Uniform but Chemically Heterogeneous Nanostructures by Nanoimprinting Demixed Polymer Blends", Langmuir 2010, 26, 14909-14914.

2. Dae Up Ahn, Zhen Wang, Ian Campbell, Mark Stoykovich, and Yifu Ding, "Influence of Substrate Surface Energy on the Morphological Evolution of Thin Films of PS/PMMA Blends", Polymer 2012, 53, 4187-4194