57th Annual Report on Research 2012 Under Sponsorship of the ACS Petroleum Research Fund

Reports: DNI950554-DNI9: Gas Expanded Lubricants - Improving Energy Efficiency Using 'Smart' Fluids

Andres F. Clarens, PhD, University of Virginia

Over the past two years,

laboratory efforts have been focused on characterizing the chemical and

physical properties of GELs under a variety of bearing-relevant conditions. In

Year 2, the phase behavior of the mixtures was characterized with a goal of

compiling results and inputting them to an industry standard model of bearing

performance. The results from this analysis are the basis for a paper under

review in Tribology Transactions. A

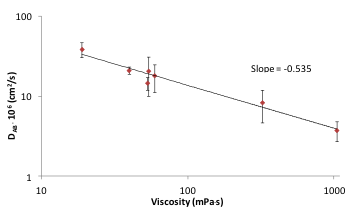

brief overview of some of the data that was collected is presented here. Diffusivity CO2 diffusivity

into a variety of representative lubricants was measured and the resulting

diffusion coefficients are plotted as a function of lubricant viscosity in

Figure 1. These results indicate greater diffusivity of CO2 into the

lubricants with lower viscosities. Polyalkylene glycols, polyalpha olefins, and

ester-based synthetic lubricants of the same viscosity have also been found to

have the same degree of CO2 diffusivity. These results are

consistent with our hypothesis and they will provide valuable practical

understanding in the design of gas exchangers and other unit operations needed

to support GEL technology deployment. Figure 1. Carbon dioxide diffusion

coefficients as a function of lubricant viscosity. Oxidative

Stability Oxidative stability of GELs

has been measured over the past year and the results suggest that the

lubricants are highly resistant to oxidation over time undergoing less

oxidation than conventional petroleum based lubricants, even in the presence of

high-pressure CO2. Our results showed little change in the viscosity

of GELs and synthetic lubricants alone over the six-week period. Modest

increases in viscosity were observed for the petroleum-based lubricants over

the same time period and under similar temperature conditions. Visually, the

GELs showed no change during this period while the petroleum-based lubricants

quickly became darker in appearance as higher molecular weight sludge formed. CO2

has been shown to accelerate oxidation of other compounds. Viscosity Extensive

efforts to characterize the viscosity of a library of GELs were initiated in

Year 1 and completed in Year 2. The viscosity of various mixtures of lubricant

and CO2 was measured for a range of pressure and temperature

conditions. Different base viscosities were selected to illustrate the effect

that CO2 can have on these mixtures. Mass fraction values were

obtained by volumetric readings on the carbon dioxide pump and mass balance

calculations. The experimental data shows a good fit with an Arrhenius type

mixing relationship. This mass fraction-viscosity relationship has been found

to accurately predict the viscosity of GELs of all lubricant types and base

viscosities for a wide range of applicable carbon dioxide concentrations. The

viscosity-composition data being generated here will form the basis for the

controllers that will be developed to regulate the composition of the GELs

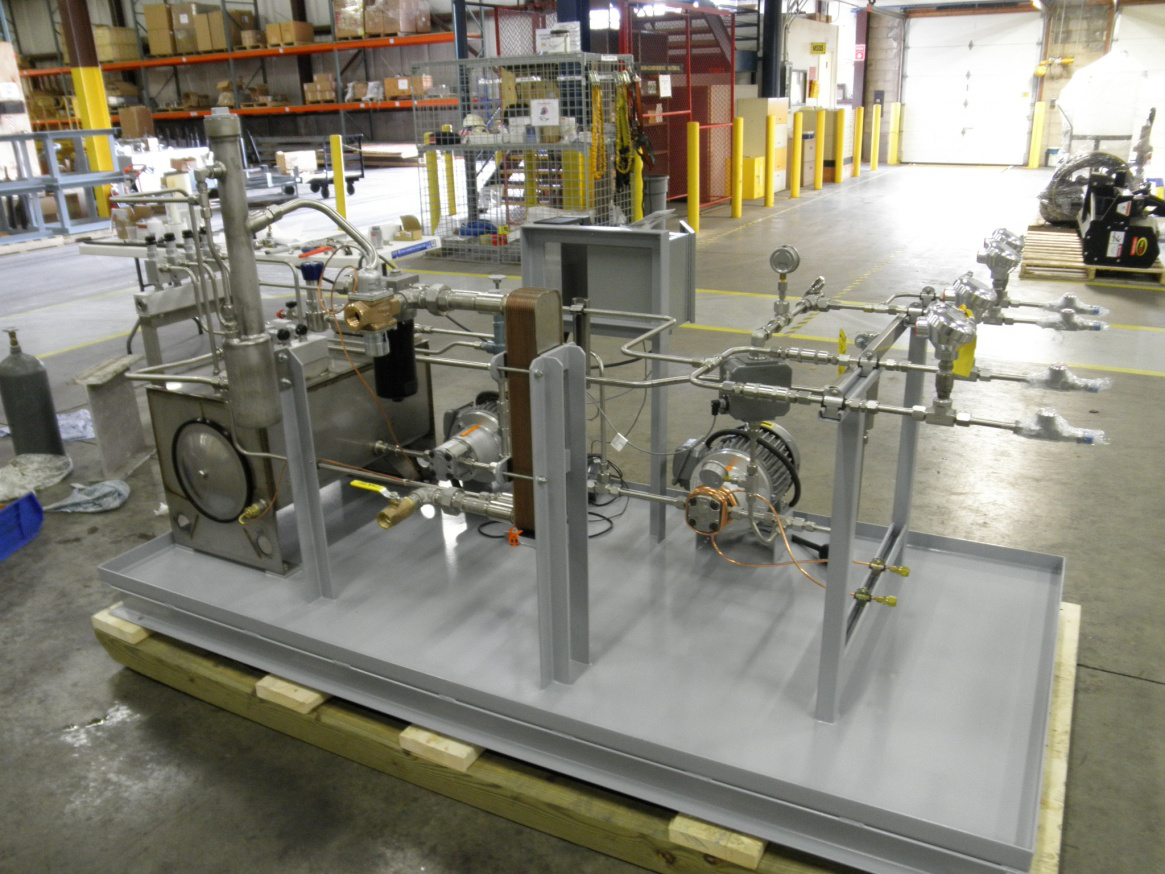

being delivered to the bearing. Task 2. Develop an experimental testbed to measure

bearing performance using GELs During

Year 2, we completed the design and began construction and assembly of the mechanical

test rig that will be used to measure the performance of GELs in tilting pad

bearings. The only remaining design detail that we are finalizing is related to

the high pressure seals that will be used to maintain the high pressure in the

bearings. These have to be custom built and we are currently conducting

computational fluid dynamic (CFD) testing of the seal design. These CFD

simulations are providing us with leakage rates and we expect that the design

will constitute novel contributions for the literature since no off-the-shelf

technology currently exists to maintain high pressures under the speeds we

expect to test. The test rig will use

a 10 hp motor capable of reaching 10,000 rpm to drive a 1.5" rotor of

approximately 42" in length. This rotor will be supported by two tilting-pad

journal bearings supplied by Lufkin-RMT, Inc., who is currently working to manufacture

the individual components. A major focus this past year has been on developing

the gas and lubricant delivery system that will generate the GELs and supply

them to the bearings. Lubricant will be fed into the system at a rate of 2 gpm

from an oil reservoir while CO2 will be provided by one or more

liquid CO2 canisters. Two pumps will supply these mixtures to each

housing. After exiting the bearing housing, the lubricant will flow back into

the reservoir where CO2 can be removed in an open-loop design. The

design of this delivery system was completed during this second year of the

project and the system has been received, pictured below in Figure 2. The

installation of this system is currently taking place as we prepare to receive

the rest of the test rig. The installation of the test bed and preliminary

experiments will be completed in the final year of the project. Figure 2. Delivery

system, built in Year 2, for pumping GELs to the test rig bearings.