AmericanChemicalSociety.com

Reports: ND5 48982-ND5: An Investigation of Rolling and Sliding Friction on the Nanoscale

W. Garrett Matthews, PhD, University of South Florida

The primary objective of the proposed research is to develop an understanding of how a nanoscale object's physical characteristics, including linear dimensions, adhesion, and elasticity, affect the tendency to slide versus roll when lateral forces are applied. The interplay between these properties will determine the transition point where a rolling mode of translocation (preferred for macroscopic objects) changes to a sliding mode. The work primarily focused on translating polystyrene microspheres across planar surfaces using the tip of an atomic force microscope cantilever while recording the torsion of the cantilever to measure the required force. Polystyrene microspheres are available in a broad range of diameters and provide a convenient system exhibiting controlled surface chemistry and mechanical properties. They also lend themselves well to surface modification through coupling chemistry, providing an additional avenue of investigation. The planar surface used as the underlying substrate is polished silicon wafer, again providing controlled chemistry and mechanics. In particular, the silicon exhibits silane reactivity via its oxide layer, allowing for facile modification of the substrate surface chemical properties. Additionally, the surrounding environment has a strong influence on the work of adhesion. Thus, the experiments will need to be done under controlled fluid environments.

Initial experiments were performed in

air to assess the suitability of the proposed experimental plan for Imaging and manipulation of the

microspheres were performed using an Asylum Reseach MFP-3D atomic force microscope

(AFM). MikroMasch cantilevers with

spring constants of 7.5 ~N/m were used, giving a torsional spring constant of

113.4 N/m. Typical experiments consisted

of 1. Imaging polystyrene microspheres deposited on polished silicon wafer

using the low shear intermittent contact mode, 2. Using the collected image, a

starting location for the tip and trajectory passing through a particle and perpendicular

to the long axis of the cantilever (for maximal lateral force sensitivity) was

selected, 3. The automated motion of the tip was performed in the so-called

contact mode, 4. During the force experiment, the cantilever position, torsion,

and normal deflection were recorded.

Such experiments were performed on the symmetric microspheres, followed

by repeating the procedure on microsphere which were subjected to large

indentation forces by the sharp point of the AFM cantilever. The indentation should introduce an

asymmetry, which would be detected in Fourier transforms of the lateral force

data collected during translation of a rolling particle across the planar

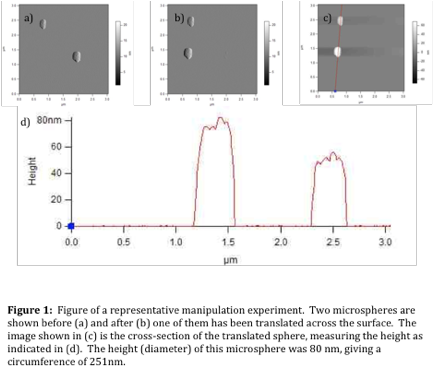

substrate. Shown in Figure 1 are two microspheres

and cross-sections measuring their diameters. Also shown is an image indicating the change in their

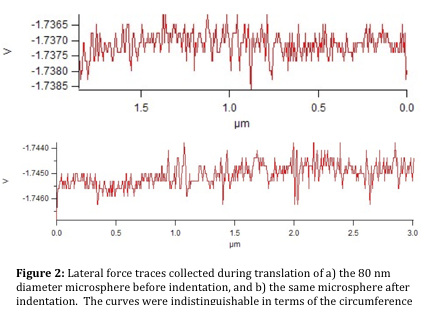

relative position after the manipulation experiment. Figure 2 shows the lateral force trace for translations

before and after indentation.

Periodic features corresponding to the dimensions of the particles were

not observed. Potentially, these results indicate

that the sphere was sliding during translation under these conditions. However, we believe the reliability of

the test for rolling behavior as described is likely to be unreliable for the following

reason. If the sphere rotated

about the axis parallel to the surface but perpendicular to the direction of

motion, it would have removed the asymmetry introduced by the indentation from

the area contacting the tip or the substrate. Thus we have begun developing an alternative experimental

approach. In conclusion, we have performed initial trials of the proposed

experiments investigating rolling friction. It was found that the experiments, as proposed, are likely

to be unsuccessful. An alternative

experimental plan has been developed and is being implemented. This new method is quite novel and has

several advantages, including increased through put for data collection.

determining the translation mode. Deposition of the microspheres was as

follows. Polystyrene microspheres were

washed three times in nanopure water: the microspheres were diluted in water,

vortex mixed, and pelleted via centrifugation. The final dilution was 0.05% solids as calculated from the

manufacturer's specification. 30 mL was then pipetted onto a 1cm2

piece of plasma cleaned polished silicon wafer and incubated for 60s at room

temperature. Afterward, the

surface was lightly rinsed with nanopure water and dried under a nitrogen

stream. The samples were then

ready for imaging/manipulation.

determining the translation mode. Deposition of the microspheres was as

follows. Polystyrene microspheres were

washed three times in nanopure water: the microspheres were diluted in water,

vortex mixed, and pelleted via centrifugation. The final dilution was 0.05% solids as calculated from the

manufacturer's specification. 30 mL was then pipetted onto a 1cm2

piece of plasma cleaned polished silicon wafer and incubated for 60s at room

temperature. Afterward, the

surface was lightly rinsed with nanopure water and dried under a nitrogen

stream. The samples were then

ready for imaging/manipulation. We are changing our procedure to test

for rolling by using a fluorescence technique. We have found a method to produce microspheres with

fluorescent dye inhomogeneously distributed on the surface of the microspheres. When imaged from below while exciting

in total internal reflection, the intensity of the fluorescent emission will

fluctuate if the particles roll – the surface bound dyes will be excited

at varying distances from the substrate surface, producing fluctuating

intensities in emission intensity.

This substrate must be transparent, so we are using quartz cover slips

instead of the silicon wafer. The

surface chemistry remains essentially unchanged. This approach has the additional advantage of allowing us to

use shear flows in microfluidic channels to produce our lateral forces,

increasing the rate of data collection.

The method also greatly simplifies the collection of data under liquids,

expanding the types of experiments that can be performed.

We are changing our procedure to test

for rolling by using a fluorescence technique. We have found a method to produce microspheres with

fluorescent dye inhomogeneously distributed on the surface of the microspheres. When imaged from below while exciting

in total internal reflection, the intensity of the fluorescent emission will

fluctuate if the particles roll – the surface bound dyes will be excited

at varying distances from the substrate surface, producing fluctuating

intensities in emission intensity.

This substrate must be transparent, so we are using quartz cover slips

instead of the silicon wafer. The

surface chemistry remains essentially unchanged. This approach has the additional advantage of allowing us to

use shear flows in microfluidic channels to produce our lateral forces,

increasing the rate of data collection.

The method also greatly simplifies the collection of data under liquids,

expanding the types of experiments that can be performed.

Copyright © American Chemical Society