AmericanChemicalSociety.com

Reports: AC9 45927-AC9: Measurement of Molecular and Thermal Diffusion Coeffcients in Model Petroleum Fluids

Abbas Firoozabadi, Yale University

In the following, we will present the modeling work, and then discuss the measurements.

Modeling of Fickian diffusion coefficients of CO2-water mixtures

The increase of CO2concentration in the atmosphere is believed to affect global warming. Various options are being examined for storage of CO2 from major sources. CO2 storage in geological formations is perhaps the most attractive and practical option (Firoozabadi and Cheng, AIChE J., 2010). CO2 injection in oil reservoirs for the purpose of improved recovery is also a partial short-term solution.

The effectiveness of CO2 storage in saline geological formations, and CO2-improved oil recovery depend on the rate of dissolution of CO2 in the brine and in the oil (Hoteit and Firoozabadi, SPE J., 2009; Firoozabadi and Cheng, AIChE J., 2010). The rate of dissolution depends strongly on diffusion flux and consequently on diffusion coefficients. While there are limited data for CO2-hydrocarbons over a wide temperature and pressure range, this is not the case for CO2-water. Most of the data for diffusion of CO2 in water are at temperatures less than 90°C. There are few data points for diffusion coefficients of H2O-CO2 system at pressures encountered at CO2 sequestration in saline aquifers.

We have developed a simple model that accurately describes the infinite-dilution diffusion coefficients for CO2 in water at both dilution limits. We also estimate the composition-based Fickian diffusion coefficients in CO2-rich and water-rich mixtures. We account for the polar nature of water molecules and polarizability of CO2 molecules. Water molecules have a large permanent dipole moment that causes formation of aggregates of its molecules. CO2 has no net dipole moment, but due to its polarizability, it can have induced in the presence of an electric field. When a water molecule approaches a CO2 molecule, a dipole-induced-dipole interaction is produced. The result is the formation of water-CO2 clusters.

Our unified approach for infinite-dilution diffusion coefficients of CO2-H2O mixtures is based in part on the corresponding state principle. We take into account the temperature effect in the total dipole moment of water and the induced-dipole moment of CO2, along with other thermodynamic variables. A single expression is found to describe diffusion coefficients of water infinitely diluted in CO2 as well as CO2 infinitely diluted in water as function of temperature, pressure, molecular mass, dipole moment, molar density and viscosity.

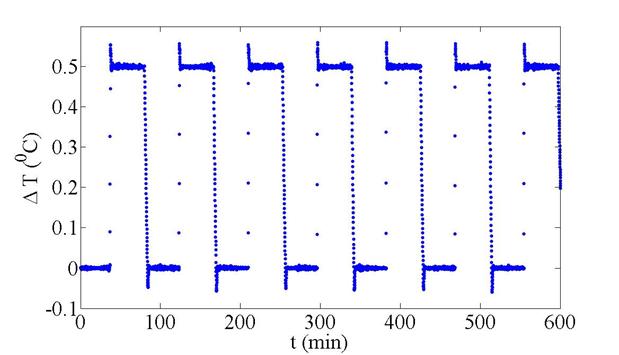

Figure 1 shows comparison of our model results with experiments based on 180 data points for 273 K ≤ T ≤ 368 K and 0.1 ≤ P ≤ 39.2 MPa and 8.9 × 10-10 ≤ D∞ ≤ 2.45 × 10-5 cm2/s.

The model is then used to predict infinite dilution diffusion coefficients outside the range of data used for CO2 -H2O, and for propane-H2O, pentane-H2O, and H2S-H2O. The predictions are in agreement with data.

We have also used the irreversible thermodynamic approach (Ghorayeb and Firoozabadi, AIChE J., 2000) to predict the effect of concentration on diffusion coefficients of H2O-CO2 mixtures.

Figure 1.

Diffusion coefficients of CO2 and water at infinite dilution (D∞)

Experimental Measurements

of Thermal Diffusion and the Soret Effect Using a

Deflected Laser Beam Thermal diffusion arises when a

temperature gradient is imposed across a material, and can cause either mixing

or unmixing of the components. Measurements are available in the literature

for the thermal diffusion of liquid mixtures and large solute systems. However, unanswered questions remain about

the underlying physical phenomena, including the dependence on solvent

interactions and the molecular size and shape of the components. In practical applications, thermal diffusion

can facilitate separations and provide sample characterization, as seen in

thermal field flow fractionation for polymeric characterization (Weigand, J. Phys. Cond. Matt., 2004).

At the same time, measurements of

the diffusion constant provide a basis for theoretical investigation of real

mixtures. Thermal diffusion can be an

important aspect of reservoir modeling and simulations.

Our setup to measure thermal

diffusion consists of a temperature controlled cell through which we pass a

laser beam. We impose a temperature

gradient across the sample and monitor the resulting change in concentration by

recording the deflection of the laser beam as a function of time. Both thermal and molecular diffusion

coefficients can be extracted from the deflection of the laser beam using

established theory (Haugen and Firoozabadi, J. Phys Chem. B, 2006; Zhang,

Briggs,Gammon, Sengers, J. Chem. Phys.,1996).

This past year we have rebuilt

our experimental set-up and improved both the stability of the laser line and

the closed loop temperature control system.

This set-up consists of two copper plates sandwiching a quartz glass

ring. The temperature on the copper

plates is controlled through an electric circuit consisting of power supplies

directing current through thermofoil heaters on each

plate. The setup is controlled in a

close loop fashion through PID software run through LabView,

which allows for all aspects of the experiment to be monitored and controlled

simultaneously. The implementation of

this closed-loop computer control system has resulted in tight temperature

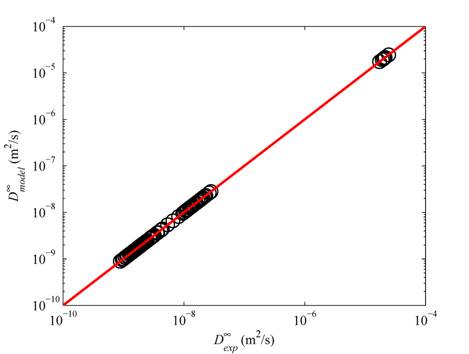

control on the copper plates. Figure 2

shows the PID-controlled temperature on the top and bottom plates. Figure 3 shows the imposed temperature

difference, stable to within 2.3 mK,

which can be turned on and off many times in a row, to allow for a more

thorough assessment of the experimental measurements.

Testing demonstrates that the setup

is working properly. Measurements of an equimolar mixture of hexane and toluene give a Soret coefficient of ST =

4.6x10-3 K-1, which paramaterizes

the fit shown in Figure 4. This value is within 5% of other laser-beam

deflection measurements on the same system.

During the coming months we intend to extend measurements using this

setup to novel systems.

Figure 2: The temperature on the

top plate is shown in green, and the bottom plate in

blue, controlled by thermofoil heaters and a PID

loop, for approximately 3.5 hours.

Figure 3: The temperature gradient between the two

plates can be stably turned on and off for many cycles at a time.

Figure

4: Laser beam deflection in an equimolar mixture of hexane and toluene, given

an imposed temperature gradient of 0.5 °C.

Copyright © American Chemical Society