AmericanChemicalSociety.com

Reports: ND9 49302-ND9: Bubble Detachment on Micro/Nano Structured Solid Surfaces in Energy Applications

Sung Kwon Cho, PhD, University of Pittsburgh and Chang Hwan Choi, PhD, Stevens Institute of Technology

The goal of this project is to develop a new method to enhance bubble detachment and to investigate the detachment mechanism. A key idea is to engineer micro/nano structured surfaces. This is a collaborative project between University of Pittsburgh and Stevens Institute of Technology. In this first year, our efforts have been mainly focused on developing and manufacturing nanostructures surfaces. To do that, we developed a new Lloyd-mirror interference lithography (IL) system that can significantly increase the nanopatterning area with great controllability of pattern periodicity.

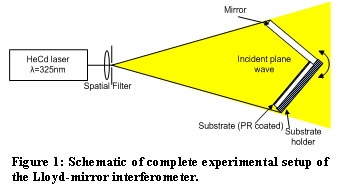

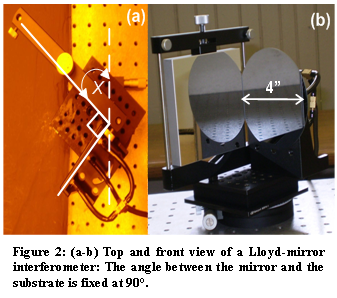

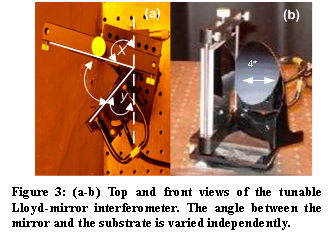

IL via a Lloyd-mirror interferometer is a popular configuration that has been widely used as a simple and efficient nanopatterning method with superior control of pattern periodicity over a relative large area. Figure 1 shows the schematic of the interference lithography set-up developed for the study. However, due to the constrained geometries in the Lloyd-mirror interferometer (i.e., a fixed mirror angle relative to a substrate), a coverage area begins to diminish significantly as a pattern periodicity passes a critical threshold at a given mirror size. Figure 2 shows the constructed Lloyd-mirror interferometer of the fixed angle at 90°. When an angle of rotation is applied in a Lloyd-mirror interferometer, the relative distance between two interfering beams is changed, affecting the total area exposed. The additional distance required for one beam to travel with respect to the other beam is called as optical path difference (OPD). A higher OPD results in a lowering of the fringe visibility or contrast. In turn, the contrast determines the quality of patterns covering the maximum possible area in an IL system. Therefore, to achieve maximum coverage area, it is essential that the total OPD of the interfering light beams is kept at a minimum, while the total area exposed is maximized. In this project, in contrast to the conventional Lloyd-mirror configuration of a fixed mirror angle, a reconfigurable Lloyd-mirror configuration of a variable angle has been designed, analyzed, and tested. Figure 3 shows the modified Lloyd-mirror interferometer capable of independently tunable angles. For a light source, a HeCd laser (a wavelength of 325 nm, a coherence length of 30 cm, power of 50mW, and σ of 425 MHz) was used. A 4”x4” square mirror with UV enhanced aluminum coating and a surface flatness of l/4 was chosen for the interferometer. The laser beam was spatially filtered in a spatial filter system equipped with a 5 µm pinhole. The filtered beam was then expanded over a distance of ~1.6 m before impinging on the interferometer. The expanded beam upon reaching the stage had a diameter ~36 cm. This large beam diameter made sure that the exposed region contained a uniform power distribution as well as a plane wave approximation necessary for uniform patterns. For PR, the PR1-2000A (Futurrex) was diluted with the principal solvent SD1 (1:10) and then spun on a 4” silicon wafer at 6000rpm/1000ramp for 30 seconds, followed by a soft-bake at 115°C for 6 minutes, giving the thickness of ~50 nm. The PR was specifically designed for the thickness to provide a quarter-wave film thickness to reduce excessive reflections off the substrate during exposure. The exposure dose for the spun thickness was experimentally determined to be 20 mJ/cm2 and development was done in developer RD6 diluted 1:1 with water for 10 seconds.

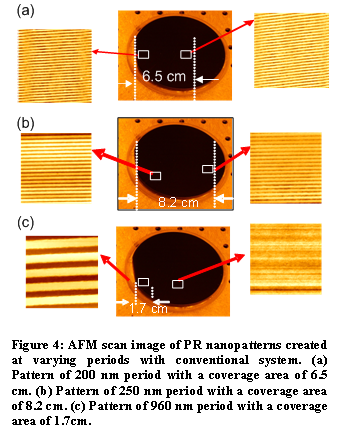

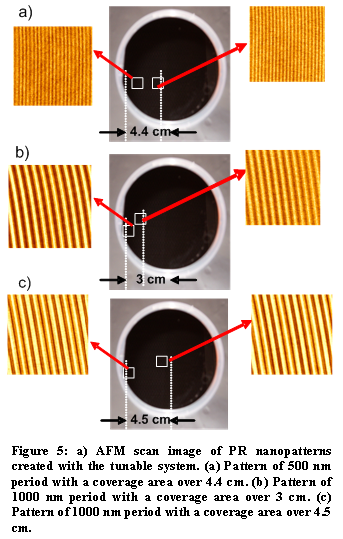

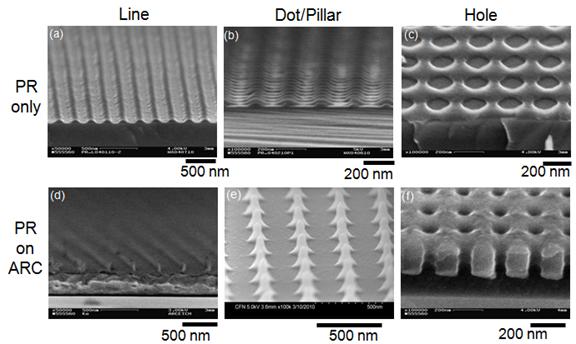

Figures 4 and 5 show the fabrication results of nanostructures for varying pattern periodicity, showing the correlation between the pattern period and the maximum coverage area for the conventional (Fig. 4) and new (Fig. 5) IL systems, respectively. If we compare Fig. 4c with Fig. 5c, it clearly demonstrates that much larger pattern coverage area can be obtained by using the tunable Lloyd-mirror system developed in this study (i.e., 4.5 cm vs. 1.7 cm for periods ~1000 nm). Figure 6 also shows various nano-pattern types created on a silicon substrate by using the interference lithography processes. It shows that high-aspect ratio PR nano-patterns can be fabricated by using the anti-reflective coating (ARC). Such high-aspect-ratio nanostructures are essential to enhance the bubble detachment.

The tunable-angle Lloyd-mirror system developed through this project keeps most of the advantages of a traditional Lloyd-mirror interferometer such as stability and simplicity of operation in place, while the overall productivity of the system, i.e., the pattern coverage area for large periods is significantly increased. The tunable system would work as complimentary system to the fixed angle system. Smaller periods could be exposed on the fixed angle system, and for large periods the system could be easily modified for large periods. Such enhanced nanopatterning capability will benefit research on nanoscale materials and fabrication technology. In parallel, we are establishing an experimental setup including a video system and a measurement system of detachment force using a MEMS load cell. In the second year, we will focus on examining the fabricated nanostructured surface to minimize the detachment force and to investigate the detachment mechanisms.

Copyright © American Chemical Society