AmericanChemicalSociety.com

Reports: G7 47999-G7: Hierarchically-Assembled Segmented Polyurethanes: Mechanical Reinforcement in a Multi-Phase Elastomeric System

LaShanda TJ Korley, Case Western Reserve University

An examination of natural materials, such as bone, collagen and spider silk, have revealed that a key design component is a hierarchical architecture that, under deformation or stress, can utilize the multiple levels of organization to absorb energy and reinforce the material such that it will not fail or permanently deform even in complex environments.

The

goal of this research is to design hierarchically-assembled segmented

polyurethanes with enhanced mechanical function by incorporating peptidic

units within the soft phase, which is motivated by recent enhancements in

toughness through the introduction of crystalline units in the continuous

domain of polyurethanes, highlighting the role of soft domain ordering as an

additional energy-absorption mechanism in these materials.

Segmented polyurethanes (PUs) are multi-block polymers usually consisting of an

amorphous, flexible soft segment and a rigid crystalline or high glass

transition temperature (Tg) hard segment. The flexible

segments form a continuous domain, which is anchored by physical crosslinking

of the hard segment aggregates. The dynamic framework of PUs offers many

adjustable routes. We propose to modify a poly(dimethysiloxane) (PDMS)

soft segment by incorporating a polypeptide, poly(benzyl-L-glutamate) (PBLG),

that is known to fold into defined secondary structures at the terminus

of PDMS (Figure 1). We expect that the peptidic ordering within the soft

block will provide an additional energy-absorbing mechanism and enhance mechanical

toughness.

The

goal of this research is to design hierarchically-assembled segmented

polyurethanes with enhanced mechanical function by incorporating peptidic

units within the soft phase, which is motivated by recent enhancements in

toughness through the introduction of crystalline units in the continuous

domain of polyurethanes, highlighting the role of soft domain ordering as an

additional energy-absorption mechanism in these materials.

Segmented polyurethanes (PUs) are multi-block polymers usually consisting of an

amorphous, flexible soft segment and a rigid crystalline or high glass

transition temperature (Tg) hard segment. The flexible

segments form a continuous domain, which is anchored by physical crosslinking

of the hard segment aggregates. The dynamic framework of PUs offers many

adjustable routes. We propose to modify a poly(dimethysiloxane) (PDMS)

soft segment by incorporating a polypeptide, poly(benzyl-L-glutamate) (PBLG),

that is known to fold into defined secondary structures at the terminus

of PDMS (Figure 1). We expect that the peptidic ordering within the soft

block will provide an additional energy-absorbing mechanism and enhance mechanical

toughness.

During Year 1, we successfully synthesized the desired peptidic soft segment (~5000 g/mol, ~10 PBLG repeat units, polydispersity <1.1) through the Deming method (Macromolecules, 2001, 34, 4348; Macromolecules, 2002, 35, 2970). This synthetic method allows for controlled growth, through a Ni metallacycle, such that target molecular weight and polydispersity can easily be obtained. The peptidic soft segment has been incorporated into two polyurethanes, containing either a crystalline (hexamethylene diisocyanate/1,4 butanediol; HDI-BDO) or amourphous, high Tg (isophorone diisocyanate/1,4 butanediol; IPDI-BDO) hard domain as well as two model polyurethanes with either HDI or IPDI hard segment and PDMS as the soft segment. Table 1 lists GPC determined molecular weights and polydispersities. The molecular weight of the HDI-BDO-PDMS SPU was not determined due to limited solubility.

In Figure 2, it is observed that both non-peptide based PUs) lose significant mechanical properties (~-115 ºC) corresponding to the Tg of PDMS. While the non-peptidic HDI polymer maintains mechanical integrity to higher temperatures, the IPDI polymer flows at 62 ºC. The PUs containing the peptide segment retain enhanced mechanical integrity until ~15 ºC (PBLG Tg). The storage modulus (25 ºC) of both peptidic PUs was increased; the storage modulus of IPDI elastomer was increased (~100x) via peptide inclusion.

Year 2 has focused on the tensile properties and the morphological characteristics. Through the addition of the polypeptide segments, the elastic modulus has been improved by nearly a factor of 4, 71.3 MPa to 252.7 MPa, but, as expected, a reduction in extensibility is observed (Table 2). Despite the decrease in elongation, their potential as impact/scratch resistant films and coatings is highlighted by the enhancement in toughness at 3% strain, which was increased (3x) from 0.08 MJ/m3 to 0.24 MJ/m3.

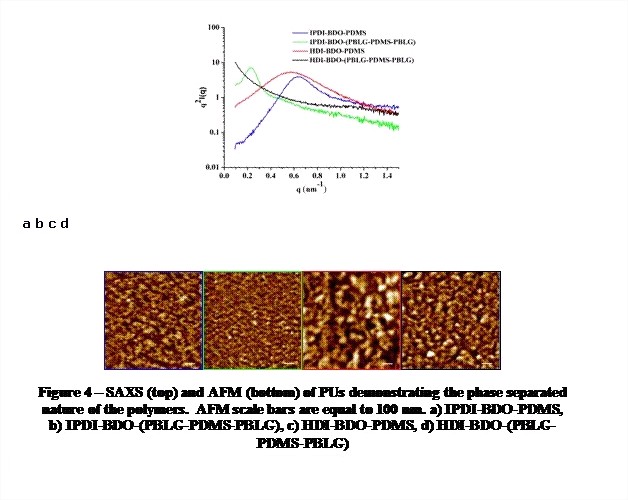

Morphological studies suggest that these multi-phase elastomers not only have short-range peptidic ordering, but are also microphase-separated Microphase segregation and well-defined soft domain ordering suggest hierarchical assembly.

Figure 3 highlights the short-range ordering, where a diffraction peak at 5.1° is indicative of a β-sheet conformation in peptidic PUs. Additionally, HS crystallinity of the HDI PUs is not disrupted. In Figure 4, SAXS and AFM data highlight a microphase-separated morphology. Both non-peptidic PUs have ~11 nm domain spacing, while the peptidic, IPDI based PU has a 29.5 nm domain spacing. A phase-separated microstructure is essential to realizing the synergistic contributions of each PU component to the overall mechanical behavior.

|

|

Funded by a NSF CAREER grant with preliminary data supported by this ACS PRF, further X-ray analysis and AFM will be utilized to understand how the peptide units contribute to this enhanced thermomechanical behavior. Coupled X-ray scattering and deformation studies will contribute to a structure-property profile that will support development of hierarchically-structured materials with tailored mechanical response. A manuscript is in preparation summarizing these findings.

Copyright © American Chemical Society