AmericanChemicalSociety.com

Reports: DNI9 49744-DNI9: Effect of Polymer and Polymer Gel on Disproportionate Permeability Reduction to Gas and Water for Tight Gas

Baojun Bai, PhD, Missouri University of Science and Technology

Background

Excess water production is one of the most prevalent operational problems facing gas companies. Water production creates problems, such as water blocking, phase trapping, and liquid dropout in the wellbore which builds back pressure on the formation causing the wells to be log off. Polymers and polymer gels have widely been used to control excess water production in conventional hydrocarbon production assets. Water/oil or water/gas flows in porous media are strongly modified in the presence of polymers or polymer gels on the pore. Laboratory studies and field tests have demonstrated polymer can reduce the permeability to water (Krw) much more than that to oil (Kro) or gas (Krg). So the polymers or polymer gels are often called Disproportional permeability reducer (DPR) or relative permeability modifier (RPM). However, previous experiments on DPR were most focused on conventional rocks without fractures. However, tight gas as a promising alternative energy resource of conventional hydrocarbon, the conduits for fluid flow in tight and shale gas reservoirs are primarily the natural fractures which have high permeability but low porosity. The paths to fluid flow in tight gas after polymer treatment for water control still have to be those fractures, usually microfractures. However, there is no published literature to report to what extent that polymer can reduce water permeability more than to gas permeability in fractured flow path, and none and less on the mechanisms behind the disproportionate permeability reduction.

Objectives

The overall objective of this project is to advance the fundamental science and the in-depth understanding of disproportionate permeability reduction mechanisms of polymer to gas and water in tight gas. Using this knowledge, we can design new relative permeability reduction agents that will lead to maximize the disproportionate permeability reduction of relative permeability modifier (RPM) to gas and water in gas shales during gas production. Applications from these study results would provide information towards the implementation of the novel concepts on RPM as well as improve results of mitigating excess water production from tight gas reservoirs.

Preliminary Results

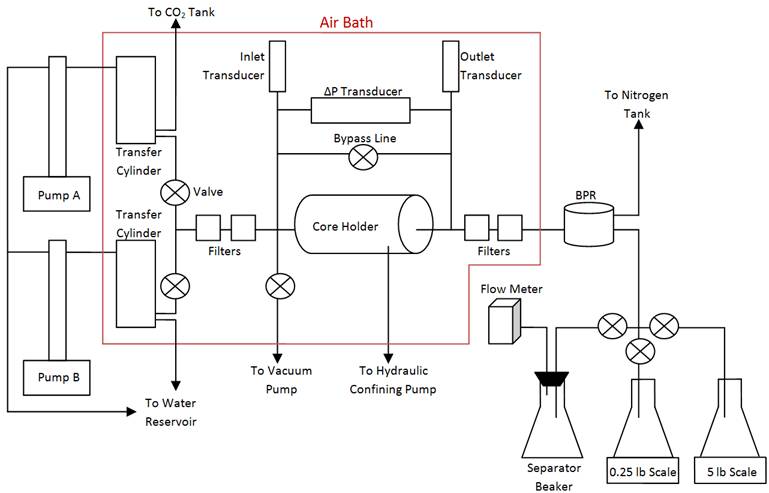

1. Core Flooding System Was Setup and Tested

We setup a new apparatus which can be used to carry out core flooding tests shown in Figure 1. Both water and gas permeability tests have been run using a sandstone core to help locate any problems or leaks.

Figure 1. Coreflooding setup 2.

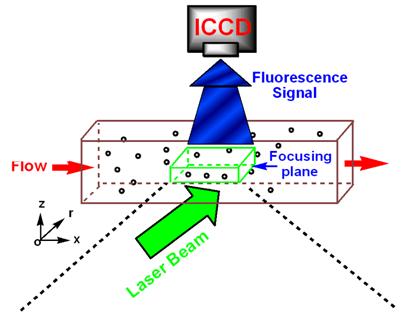

Visualized Micro model Systems Was Successfully Setup and

Tested Fused-silica

square capillary was developed to function as sample fracture for monitoring

fluid flow behavior; the capillary was equipped with holder and tubing which

was designed to fit the microscope stage. Briefly, A Figure 2. Optical arrangement

for single molecule detection system Figure

3. Localized probing region of single molecule imaging system 3.

PoreMaster Was Purchased to Measure Pore Size Distribution

in Shale PoreMaster 60 porosimeter generates pressure to 60,000

psia for pore size analysis from over 950 micron to 0.0036 micron pore

diameter. Preliminary results show that the size distribution of pores and

microfractures can be obtained (Figure 4).

(a) PoreMaster 60 (b) shale sample (c) Pore size distribution of a shale sample Figure 4. Poremaster and a representative

results of pore distribution in a shale rock Future

Work 1.

Test the extent to which typical relative permeability

modifiers (RPM) reduce water permeability more than gas permeability for tight

gas rocks with fractures using the apparatus shown in Figure 1. 2.

Study the mechanisms of disproportionate permeability

reduction using the apparatus shown in Figures 2 and 3.

Copyright © American Chemical Society