AmericanChemicalSociety.com

Reports: G10 48227-G10: A Systematic Study on Vapor-liquid-solid (VLS) Growth Process of Metal Oxide Nanodendrites

Pu-Xian Gao, University of Connecticut

During the past year, we have conducted the investigations on the self-catalyzed vapor-liquid-solid growth process of metal oxide nanodendrites directly converted from metal oxide nanofilm. Particularly, we have investigated the graphite effect on nanofilm-nanowire/dendrite conversion under carbothermal condition.

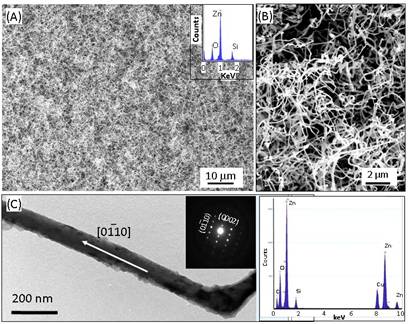

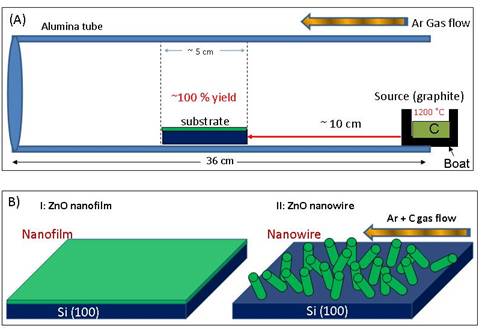

In the last report, the graphite was found to demonstrate a unique ‘catalyst' effect on in-situ conversion of ZnO nanofilm into nanowires and into nanodendrites. To investigate the graphite effect, a comparative experimental and theoretical study has been carried out. To start with, ~3 gram graphite powder loaded was used as the source material and kept in the tube furnace center, as shown in the Fig. 1a. Silicon substrate sputtered with 50 nm ZnO nanofilm was placed ~10 cm away from the source. During the experiment, the furnace was heated to 1200 °C with a 25 °C/min ramping rate and kept for 2 hours. The pressure was controlled at ~100 mbar when temperature reached 1000 °C and carrier gas Ar was initiated at 20 sccm. During the cooling period, Ar gas was stopped when temperature reached at 1000 °C. Fig. 1b shows the schematic of final result where silicon substrate sputtered with ZnO nanofilm (50 nm) converted into uniformly distributed ZnO nanowires with a ~100 % yield at a temperature range of ~800-900 °C. A JEOL JSM 6335F field emission SEM and an FEI Tecnai 12 STEM were used to characterize the morphology and structure of the converted nanowires. The composition was determined by EDX spectrometers attached to the SEM and TEM.

Fig. 1 (a) A schematic in-situ

carbothermal set-up of ZnO nanowires. (b) A Schematic diagram of ZnO nanofilm conversion

into ZnO nanowires in the presence of graphite source and carrier gas

flow.

Fig.

2a is a top-view SEM image of large scale as-converted zig-zag ZnO nanowire and

the inset displays the EDX spectrum revealing the presence of Zn, O and Si.

Silicon peak appears due to the Si substrate. Fig. 2b shows the converted ZnO

nanowires ~100 nm wide and microns long. A typical TEM image of zig-zag ZnO

nanowires and the corresponding selective area electron diffraction (SAED)

pattern in Fig. 2c reveals the single crystalline wurtzite structured nanowire

grown along [01-10] direction. Fig. 2d is an EDX spectrum of a single nanowire

confirming the composition of ZnO nanowire, while the copper peak due to TEM

grid. Here, sputtered ZnO nanofilm has a (0001) orientation as proved by the

x-ray diffraction pattern shown in Figure 3a, which is energetically more

favorable, compared to (11-20) and (01-10). The zig-zag nature of the grown ZnO

nanowires with growth direction of [01-10] is consistent with the early report

suggesting that zig-zag structure of nanowires results from the periodic change

in equivalent growth directions of <01-10>, i.e., from [1-100]à[10-10]à[01-10]à[10-10].8 Fig. 2 (a) Low magnification SEM image

of zig-zag ZnO nanowire. Inset picture shows the EDX spectrum of ZnO nanowires.

(b) high magnification SEM image. (c) TEM image of ZnO nanowire and inset shows

the SAED pattern of the nanowire with growth direction along (01-10). (d) EDX

spectrum of single nanowire in TEM.

In order to investigate the

conversion process of [0001] oriented ZnO nanofilm into [01-10] nanowires, an

array of comparative experiments has been designed and conducted, as listed in

table I.

Table 1.

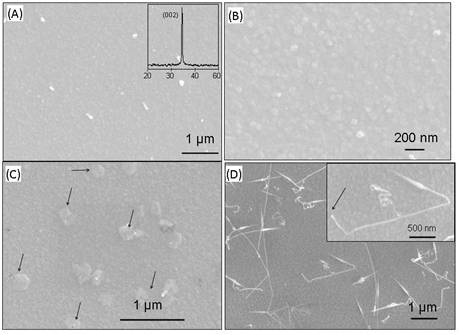

Temperature Duration (minutes) Argon (20 sccm) Carbon (~3g) Result 1200 °C 60 absent absent Nanoislands formation (Fig. 3a) 60 present present Bigger nanoisland formation due to coarsening (Fig. 3c) 90 present present Nanowires grown from nanoisland, ~30-40% yield (Fig. 3d) 120 Present Present ~100 % yield ZnO nanowire (Fig. 2a-b) The involvement of graphite and

Ar flow simultaneously has been suggested to be necessary through the

experiments observations and rational comparison. With a 50 nm ZnO coated

silicon substrate subjected to the annealing at ~800-900 oC for 1

hour in absence of graphite and carrier gas, 20-50 nm ZnO nanoislands formed

quite uniformly (Fig. 3). The inset x-ray diffraction pattern in Fig. 3a shows

that the nanoisland-based ZnO film kept its textured (001) orientation. The high

temperature process clearly transforms as-sputtered ZnO nanofilms from smooth

flat surfaces to rough surfaces with coarsened grain.9 These

nanoislands still has preferential alignment along (001) direction after

annealing. Upon annealing for 1 hour at 800-900 oC, with Ar carrier

gas and graphite source (Fig. 3c), the ZnO nanoisland size further increased

and some nanoislands were bigger compared to others due to coarsening effect.

This coarsening phenomenon is due to a natural self-organization of the surface

adatoms driven by the reduction of surface area, therefore surface energy. The

equilibrium state could not be attained here, as the nanoisalnd ripening

process is opposed by diffusion or interface mass-transfer barriers. With

graphite source and Ar carrier gas, another hour and half long annealing

process clearly bring up the nucleation and growth of nanowires, as evidenced

in Fig. 3d. These nanowires are 2-10 mm in

length and less than 100 nm in diameter. Inset picture clearly shows that

nanowire has grown from the nanoisland as indicated by an arrowhead. This

result suggests that as the temperature increases, nanofilm breaks down into

the nanoislands12 (Fig. 3c), with increasing temperature, induced

stress on the nanofilm leads to the formation of nanorods or nanowires to

reduce the surface energy and the pass-by gas flow (carbon + Ar) during

synthesis could provide the transient reduction and in-situ recombination of

comprised atoms in the deposited compound (Zn-O in our case), therefore could

favor nanowires formation11.

Fig. 3 (a) A typical SEM image of ZnO-coated

silicon after 1-hour annealing in absence of graphite source and Ar carrier

gas. Inset shows the XRD pattern retaining (001) orientation before and after

annealing of 50 nm ZnO sputtered silicon substrate. (b) high magnification SEM

image revealing nanoisland formation. (c) SEM image of sputtered ZnO nanofilm

for 1 hour in presence of graphite source and Ar carrier gas. (d) ZnO nanowires

grown from the nanoisland at 1 hour 30 minute in presence of Ar and graphite.

Inset picture shows that nanowire growing from nanoisland.

Copyright © American Chemical Society