AmericanChemicalSociety.com

Reports: B7 46763-B7: New Membranes for Enhanced Purification of Natural Gas at the Wellhead

Chad J. Booth, Texas State University

The underlying goal of this project was to develop a new series of semi-fluorinated polyimides (PIs) which exhibit enhanced selectivity without loss to permeability. These new materials were designed to be utilized as permeable membranes for the separation and purification of natural gas. While traditional systems rely on a combination of the inherent chemical structure along with the “tortrous path” theory for the particular permeation to occur, our use of nano-dispersed TiO2 is designed to decrease the rate of permeation of the methane. The decrease occurs due to the surface adsorption of the methane onto the TiO2 nanoparticles. The overall system, is therefore, designed to remove any “other” gases present in the mix first (their permeation rate will not be affected by the presence of the TiO2).

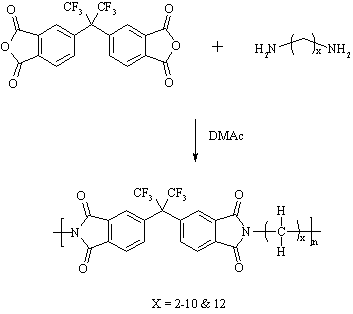

During the first year of the project we synthesized and characterized a novel homologous series of PIs (Figure 1) using 6-FDA and a series of a, w -alkanediamines. The diamines include 1,2 through 1,10 as well as the 1,12. The new materials exhibit excellent thermal stability (figure 2a) and are capable of forming transparent sustainable films.

Figure 1: Synthetic scheme used to achieve the polyimides (x = 2-10 and 12)

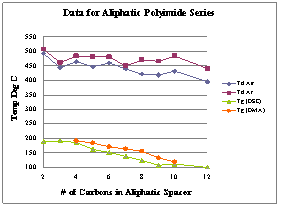

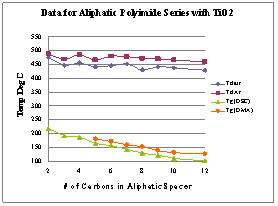

During the second year we completed the synthesis and thermo/mechanical characterization of the nanocomposite series (figure 2b). In addition, we began to obtain permeation data on several of the native series.

TGA data was recorded at 10% weight loss and molecular weight was determined using GPC (using polystyrene standards). This data, except for the molecular weights which averaged from 70,000 to 150,000 g/mol, is summarized in figures 2a and 2b.

The traditional trends expected for a homologous aliphatic series of monomers upon inclusion in a polymer system are indeed present in these materials. Not only do they display decreasing thermal/mechanical performance as the length of the aliphatic spacer is increased, they also clearly display an “odd-even” effect, out to about seven carbons.

a b

Figure 2: Thermo/Mechanical Data for a) Native Polyimide Series and b) Nanocomposite Series

In the final year we continued the testing of the above mentioned materials (both the native materials as well as the nanocomposites) to establish their gas permeation ability. These values will be used for the comparison of selectivity verses permeability of the native material and the materials with TiO2 incorporated into the matrix. The hypothesis is that if two series of PIs are examined, differing only with respect to the inclusion of the TiO2 nanoparticle, the nanocomposite will exhibit enhanced selectivity with minimal loss to permeability. The data thus far, obtained for the 5 and 6 carbon aliphatic chains, show excellent selectivity (table 1).

Table 1: Permeation data to data

Material | H2 | CH4 | CO2 | ||

2 atm | 3 atm | 4 atm | 2 atm | 2 atm | |

1,5 | 3.90 | 3.91 | 3.92 | 0.024 | 0.994 |

1,6 | 3.76 | 3.73 | 3.72 | 0.017 | 0.990 |

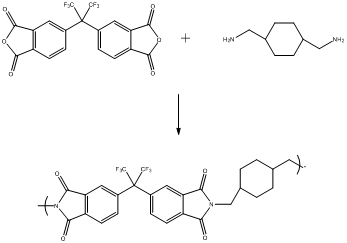

In addition, we synthesized of a polyimide (figure 3). This material contains the same dianhydride (6-FDA) shown above, but includes a rigid aliphatic diamine monomer, 1,4-bis(aminomethyl)cyclohexane (BAMC). This new series will allow the examination of the effect of polymer backbone flexibility on the materials selectivity/permeability.

Figure 3: Polyimide from 6-FDA and BAMC.

Characterization of this new material provided data as to the molecular weight and thermal stability. Molecular weight (obtained via dilute solution viscometry) gave inherent viscosities around .1 dL/g. Thermal decomposition was in excess of 465 °C with char yields less than 2% at 700 °C. Fianally the glass transition temperature (via DSC) was determined to be around 230 °C with no detectible crystallinity.

While no permeation data has yet been collected, it is interesting to note that the polyimide made using BAMC is much more brittle than those reported previously made via the use of the linear aliphatic diamine series.

Copyright © American Chemical Society