AmericanChemicalSociety.com

Reports: UR5 50095-UR5: Adsorption of CO2 by MgO Aerogels for Enhanced Steam Reforming

Mingheng Li, PhD, California State Polytechnic University

Introduction

Adsorption Enhanced Reforming (AER) is a novel steam reforming technique that enables the production of fuel-cell grade hydrogen in a single step. When CO2 is removed from the reforming process, the water gas shift (WGS) reaction (CO + H2O = CO2 + H2) shifts to the right which results in a relatively lower reforming temperature and also an enhancement of the yield and purity of H2. The major CO2 adsorbents reported in AER are hydrotalcites (Mg6Al2(CO3)(OH)164H2O) and CaO-based materials. This research project is to investigate the potential application of MgO aerogels as a new adsorbent at low temperatures. The research aspects include materials synthesis and characterization as well as thermodynamic modeling.

Synthesis and Characterization of MgO Aerogels

In order to study the effects of surface defects, dopant modification, and composition on CO2 absorption of sol-gel derived MgO and MgO composites, the following materials were synthesized and characterized.

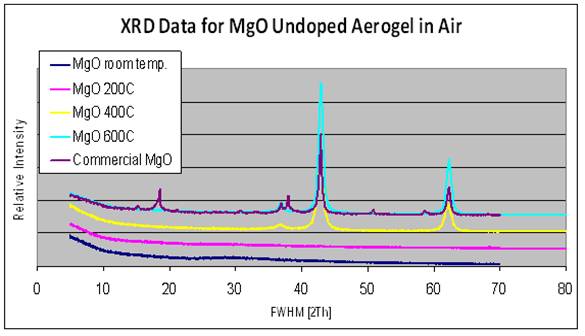

Amorphous MgO aerogels (with surface areas ~ 500 m2/g) and xerogels (with surface areas ~ 100 m2/g) were synthesized through the sol-gel process using a modified Pechini process. The MgO aerogels and xerogels are amorphous and crystallize to the periclase phase at ~ 450°C in air, without passing through the brucite phase (Figure 1).

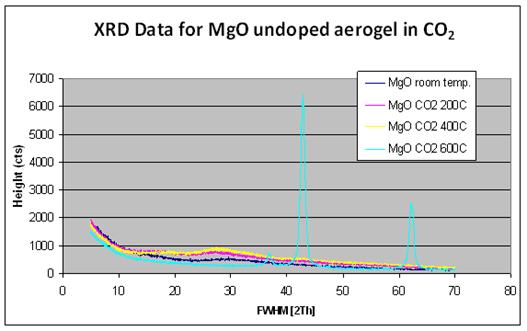

Figure 1: XRD shows that sol-gel derived MgO are amorphous and

crystallize to the periclase phase at ~ 400°C. The commercial MgO contains both

brucite and periclase forms.

This is important to note since the crystalline MgO synthesized

from sol-gel derived aerogels and xerogels are purer forms of MgO, whereas

commercially available MgO contain traces of the brucite (Mg(OH)2)

phase. The periclase phase has XRD peaks at 2¦È = 38o, 43o,

and 62° whereas the brucite phase has primary peaks at 2¦È = 19o and

39°.

When sol-gel derived MgO were heat treated in CO2

instead of air, the transition to the periclase phase was delayed until 600°C

(Figure 2). Brucite formation was also not observed for this treatment process.

Figure 2: XRD of sol-gel derived MgO

heat-treated under CO2.

MgO doped with 3 mol% of Ni and 2 mol% of Co were also

synthesized. Neither dopants changed the crystallinity of the MgO matrix and

were too low in concentration to be detected with XRD. For CO2

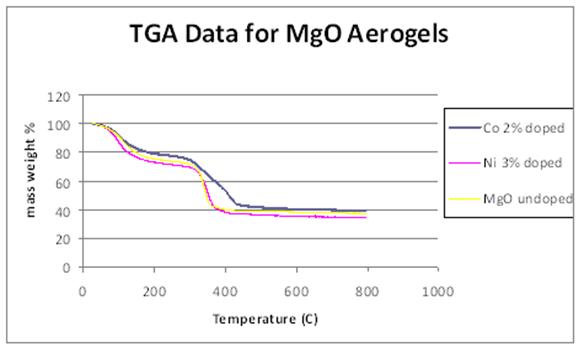

adsorption between ambient to 800°C a thermogravimetric analyzer (TGA, TA

Instruments, SDT 2960) will be used. Preliminary studies with TGA under air

were conducted to determine material evolution with heat treatment. Figure 3

shows that all samples lost approximately 60% of their initial mass due to loss

of surface adsorbed water, organic solvents (80 - 180°C, physisorbed water and

organic solvents (300 - 400°C). Doping with Ni did not change the mass loss

profile of the MgO. Doping with Co appeared to slow the desorption process. A

similar study under wet-CO2 and dry-CO2 will be conducted

to determine the adsorption behavior of these materials.

Figure 3: Mass loss profiles of MgO, Ni-doped

MgO, and Co-doped MgO.

Current work includes synthesizing Rh-doped MgO as well as a

sol-gel derived MgO-Al2O3 composite that is similar to

hydrotalcite but with higher surface areas and exhibit metastable phases not

available through the traditional synthesis process.

Thermodynamic analysis of CO2 adsorption on steam

reforming A thermodynamic model has been developed to study the effect of

CO2 adsorption on steam reforming. The model is based on the

minimization of Gibbs free energy of the reactive system with the assumption of

Langmuir isotherm:

The above model was applied to the steam reforming of ethanol

at T = 500°C, P = 5 bar and molar ratio H2O/EtOH = 3. The model was

solved based on Langrage multiplier method for and some of the results are

summarized below.

The gas composition in the product mixture under different CO2(ads)/CO2

(a parameter approximately proportional to the capacity of the adsorbent) is

shown in Figure 4. As CO2(ads)/CO2 increases,

the fraction of CO2(g) rapidly decreases to a minimal level (at CO2(ads)/CO2=101~2),

beyond which a significant reduction in the CO or CO2 concentration

is not obvious. The low partial pressure of CO2 in the gas phase

makes it difficult for a further adsorption. When CO2 is gradually

adsorbed on the surface, the forward reaction in the reversible water gas shift

reaction CO + H2O = CO2 + H2 is favored. As a

result, part of the CH4 is converted to CO through the methane

reforming reaction CH4 + H2O = CO + 3H2. In

this sense, the entire system behaves like a buffer solution. Due to the

coupling of multiple equilibrium phenomena, a complete removal of CO2

is very difficult. However, the fact that the primary carrier of carbon in the

gaseous phase is CH4 (instead of CO or CO2) at CO2(ads)/CO2

> 101 implies that a complete removal of CO2 is not

necessary.

Figure 4: Gas compositions of ethanol reforming at equilibrium

as a function of CO2(ads)/CO2 (H2O/EtOH

= 1/3, P = 5 bar and T = 500°C).

A parametric analysis based on Eq. (1) was made in a wide range

of operating conditions such as temperature, pressure, steam-to-carbon ratio and

with/without the presence of oxygen. It was shown in all cases that CO2

adsorption not only enhances H2 yield and purity, but also

suppresses the formation of coke, an undesired material that could deactivate

the reforming catalyst. For example, Figure 5 shows clearly that the coke

formation is suppressed by increased CO2 adsorption at a fixed

pressure.

Figure 5: Contour of coke formation as functions of system

pressure and CO2 adsorption.

Copyright © American Chemical Society