44403-G5

Synthesis of Inorganic Electrodes with Controlled Interfacial Structures by Crystal Engineering in Electrodeposition

(1) Synthesis

of Cu2O Electrodes Composed of Dendritic Crystals We have

demonstrated a new strategy of exploiting and manipulating dendritic growth of

Cu2O to produce photoelectrodes with high surface areas and good

electrical continuity. The

dendritic branching growth of Cu2O allowed for facile substrate

coverage and high surface roughness without growing a thick film. The resulting electrodes generated

significantly improved photocurrent compared to the electrodes composed of

micron-size faceted crystals that produced negligible short-circuit

photocurrent.

In order to

further enhance photocurrent, various methods to increase dendritic crystal

size were investigated. Increasing crystal size reduces crystal-crystal

boundary areas and ensures good electrical continuity in the larger domains of

the electrode. This can minimize

recombination losses and improve charge transport properties. Deposition potential, Cu2+

concentration, and acetate concentration were altered to regulate the

deposition overpotential, h,

which has a direct impact on nucleation

density and, therefore, on crystal size. Increasing crystal size consistently resulted in the

improvement of photocurrent regardless of the method used to regulate crystal

size. The electrode

showing the highest photocurrent was composed of dendritic crystals that

laterally expanded ca. 12000 mm2 while the thickness of the electrode was kept

below 5 mm (Figure 1).

This electrode generated more than 20 times higher photocurrent (0.45

mA/cm2) than the electrode containing the

smallest crystal size produced in our study with the average lateral size of

100 mm2 (0.02 mA/cm2). The

significant increase in photocurrent achieved simply by controlling the crystal

sizes in dendritic branching growth, without involving any compositional

changes, implies an enormous potential for morphology tailoring in improving properties of polycrystalline electrodes. (2) Synthesis of Highly

Transparent Nanocrystalline a-Fe2O3

electrodes Ferric

oxide (a-Fe2O3, hematite) is an n-type

semiconductor highly desirable for use in solar energy conversion due to its

bandgap (Eg = ~2.2 eV) that allows for utilizing the significant

portion of the solar energy spectrum. We have developed a new anodic deposition route to

prepare a-Fe2O3 electrodes using a

slightly acidic plating solution (pH 4.1). In this pH, Fe2+ ions are soluble without the

need of adding complexing agents, which simplifies the compositions of the

plating solution. Deposition in

this medium produced amorphous g-FeOOH films that can be

converted to highly transparent nanocrystalline a-Fe2O3

films by annealing. a-Fe2O3 films with

varying thickness were produced by changing deposition times in order to

investigate the effect of film thickness on photon absorption and photocurrent

generation. Films deposited for

1min, 2 min, 4 min, 8 min, and 16 min resulted in films with the average

thickness of 70 nm, 180 nm, 320 nm, 430 nm, and 680 nm, respectively, judging

from their cross sectional SEM images.

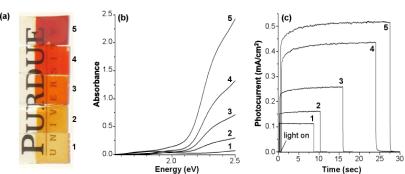

The photographs and UV-vis absorption spectra of the a-Fe2O3 films with

varying thicknesses are shown in Figure 2a-b. These films showed similar absorption features (i.e. onset

of band gap transition) but absorption increased gradually as the film

thickness increased.

The short-circuit photocurrent, which was measured

using a 60:40 solution of propylene carbonate: acetonitrile containing 0.5 M

tetrabutylammonium iodide and 0.04 M iodine, gradually increased as the film

thickness increased due to enhanced photon absorption and surface areas. However, when the film thickness

exceeds 460 nm, photocurrent decreased because severe aggregation of Fe2O3

particles at the Fe2O3/substrate interface increased

recombination losses in the film.