46864-G7

Templating Ion-Conducting Membranes Using Block Copolymers

The need for clean and sustainable energy sources is growing rapidly,

and electrochemical devices such as batteries and fuel cells are considered

promising solutions. Polymer

electrolyte membranes for use in lithium batteries and fuel cells require high

ionic conductivities to decrease the internal potential losses. Besides ionic

conductivities, adequate mechanical strength is necessary to prevent

short-circuiting between electrodes and to reduce dendrite formation in lithium

batteries. Additionally, thermal

stability, chemical resistance, and controlled permeabilities To achieve the above requirements for lithium ion batteries, block

copolymers containing conducting blocks like poly(ethylene oxide), and

complementary blocks, have been employed to vary the morphology and properties of

conducting materials. The self-assembly of these copolymers permits the design

of flexible and sturdy membranes that contain conducting channels for ion

transport. Most

copolymer/salt doping has focused on the low salt concentration regime,

analogous to ether oxygen to lithium cation ([EO]:[Li]) ratios ranging from 50:1

to 12:1; however, recent literature has shown the promise in using higher salt

concentrations. For our

studies to date, we have employed cylinder-forming poly(styrene-b-ethylene oxide) [PS-PEO] block copolymers, where the polymer electrolyte cylinders were

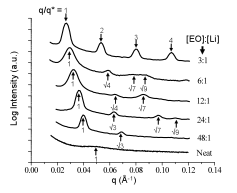

formed via a self-assembly process inside a polystyrene matrix. We show that the domain spacing of our polymers increased as the degree

of salt-doping within the PEO domains increased. This trend is shown succinctly in the SAXS profiles in

Figure 1, where the primary scattering peak shifts to smaller q with increased salt. Additionally, the neat (non-doped) material,

along with the polymers at salt doping ratios ranging from 48:1 to 6:1, d*=2p/q*

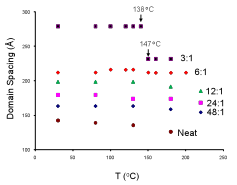

(equation 1) The complete temperature dependent behavior of the PS-PEO:LiClO4

block copolymer complexes is shown in Figure 2. One particular point of interest is the discontinuity in

domain spacing for the 3:1 sample as the temperature is cooled from 147 oC

to 138 oC. This

discontinuity was linked to the crystallization of the 3:1 EO:LiClO4

complex in a recently published work. We note that the crystallization occurred

above the glass transition temperature of the PS matrix; however, the increased

segregation strength upon doping likely promoted the confined crystallization

of the PEO domains, leading to the larger domain spacing of the lamellae below

the discontinuity. Differences

in the domain spacing between copolymers doped lithium salts at similar ratios,

but with the various counterions, also were found in this study. The LiAsF6-doped polymer

exhibited the largest characteristic size, while the LiCF3SO3-doped

polymer showed the smallest domain spacing. These differences in domain spacing are likely related to

alkali metal – counterion interactions in the presence of the We

will continue to evaluate the influence of the lithium counterions on the

thermodynamics of block copolymer self-assembly, to understand and stabilize

conducting networks and explore the conductivity of these self-assembled

materials. Figure 1.In-situ

SAXS profiles of LiClO4-doped PS-b-PEO

as a function of salt concentration. Samples were held in the SAXS under vacuum

and at 1

Figure 2.(color online) Domain spacing vs temperature

calculated from in