Reports: DNI1056144-DNI10: New Dimensions in Designing Nanohybrid Membrane Materials for Energy-Efficient Gas Separations

Ruilan Guo, PhD, University of Notre Dame

The overarching goal of this project is to develop a new and versatile platform of nanocomposite membrane materials that utilizes the unique supramolecular “interlocking” interactions induced by hierarchical iptycene units to address the interface incompatibility issue in composite membranes for gas separations. In this reporting period, following tasks have been pursued to achieve the goal:

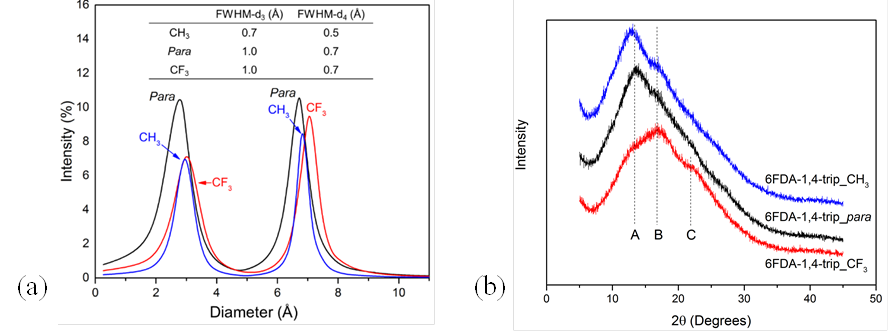

Task 1. Microstructure characterization and gas transport properties of triptycene-containing polyimides. Comprehensive characterization of the matrix polymers (i.e., triptycene-based polyimides) that would be used for the preparation of mixed-matrix membranes (MMMs) has been performed. Studies have been focused on the correlation between microstructure characteristics and fundamental gas transport properties. PALS (positron annihilation lifetime spectroscopy, Figure 1a) and WAXD (wide-angle X-ray diffraction, Figure 1b) showed that polymer chain packing and transport properties of triptycene-polyimide are highly sensitive to the substituent group adjacent to the triptycene unit. The results provide the evidence for the “internal free volume” and π-π interactions of triptycene units that can be utilized to promote the polymer-filler contact in the nanocomposite membranes. Analysis of diffusivity and solubility coefficients showed that kinetic diffusion is the dominating transport mechanism in these triptycene-polyimides whereby gas separation is realized via size discrimination. Triptycene-polyimide with CF3 groups (Figure 2) was used as the matrix to fabricate MMMs.

Figure 1. (a) Microcavity diameter and size distribution determined by PALS for triptycene-polyimides. The inlet table displays the full-width at half-maximum (FWHM) values; (b) WAXD patterns of the triptycene-polyimides showing amorphous chain packing (A), a more-ordered chain-packing domain (B), and π-π stacking (C).

Figure 2. Chemical structure of the triptycene-polyimide used for MMMs fabrication.

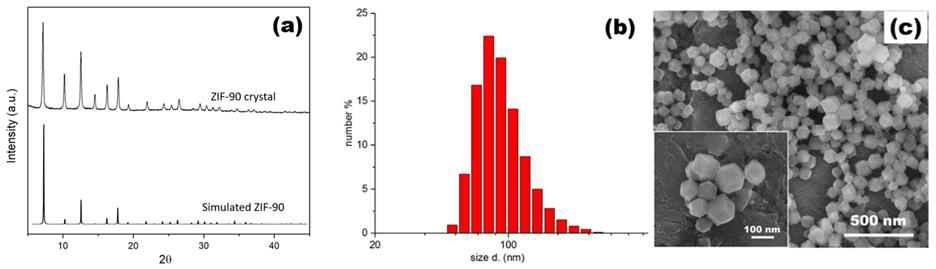

Task 2. Synthesis and surface rafting of ZIF-90 nanoparticles. A previously reported procedure was adopted to prepare ZIF-90 which could produce nanoparticles with relatively small size and high yield desired for MMMs fabrication. The synthesized ZIF-90 particles showed high crystallinity (Figure 3a) that agrees with the simulated WAXD pattern. DLS (dynamic light scattering) showed a number-average particle size of ~79 nm (Figure 3b), which is consistent with the average particle size visually observed in SEM images (Figure 3c). The calculated BET surface area (1,426 m2∙g-1) confirmed high porosity of the particles. The pristine ZIF-90 particles were used in the fabrication of MMMs with systematically varied filler loadings as controls.

Figure 3. Characterization of ZIF-90 nanoparticles by (a) WAXD, (b) DLS, and (c) SEM.

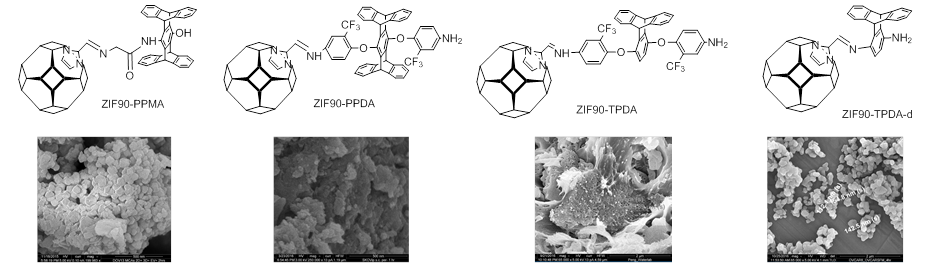

Surface modification of ZIF-90 nanoparticles has been carried out via condensation reaction between the amine functional groups of select iptycene derivatives and the aldehyde functionality of ZIF-90 particles. Various iptycene-amine derivatives were attempted for surface grafting of ZIF-90 to identify the optimal grafting chemistry (Figure 4). It was found that grafting with TPDA-d showed the balanced reactivity whereby the ZIF-90 crystallinity was well maintained after grafting without forming the “crosslinked” particles in the cases of PPDA and TPDA and the condensation was much more efficient than in the case of PPMA. As such, TPDA-d modified ZIF-90 particles were used for fabricating MMMs.

Figure 4. ZIF-90 particles grafted with various iptycene moieties.

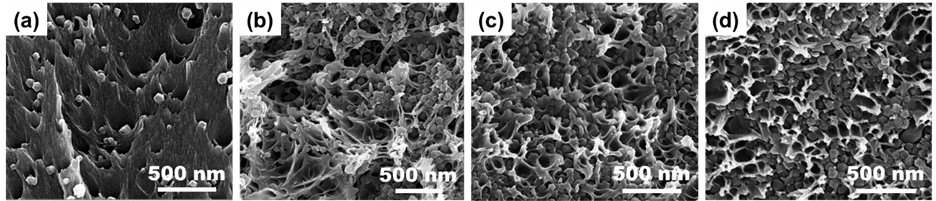

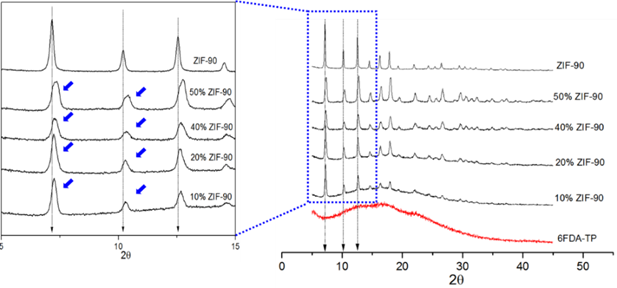

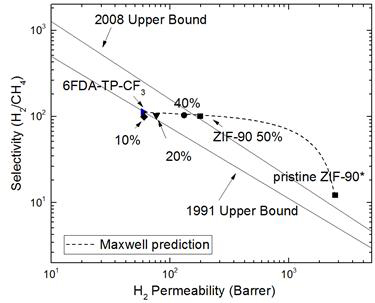

Task 3. Preparation and characterization of mixed-matrix membranes from (modified) ZIF-90 nanoparticles and triptycene-polyimide. Solution casting method was applied to prepare the composite films coupled with priming technique to promote filler dispersion in the polymer matrix and prevent particle aggregation. Composite membranes with 10-50 wt% of pristine ZIF-90 particles were prepared as the control to provide the base information of interface morphology and gas transport properties such that the results can be compared with the composite membranes with modified ZIF-90. As shown in Figure 5, no obvious interfacial voids/defects were observed in all composite membranes containing pristine ZIF-90 even at very high loadings (50 wt%), indicating excellent polymer-filler compatibility. Additionally, the overall spherical shape of the fillers as compared to the angular shape of pure ZIF-90 particles (Figure 3c) suggests strong polymer-filler affinity. Notably, WAXD analysis (Figure 6) showed that the characteristic ZIF-90 peaks in MMMs shifted toward higher 2θ angle than those of pure ZIF-90, suggesting that ZIF-90 crystals were slightly constrained and contracted by the surrounding polymer chains. This observation further suggests good filler-polymer compatibility in these composite membranes. Gas transport properties were analyzed for these control membranes via pure gas permeation tests (35 °C, 3-17 atm feed pressure). The composite membranes show significantly enhanced gas permeability with relatively constant ideal selectivity with increasing ZIF-90 loading. Membrane separation performance surpassed the 2008 upper bound at 50 wt% loading (Figure 7). The trend matches reasonably well with the Maxwell model, corroborating the SEM observations of defect-free interfacial morphology.

Figure 5. SEM cross-section images of ZIF-90/6FDA-TP composite films with (a) 10 wt% (b) 20 wt% (c) 40 wt% (d) 50 wt% loading of pristine ZIF-90 nanoparticles.

Figure 6. WAXD patterns of the pristine triptycene-polyimide film and composite membranes. Arrows indicate the shifts in peaks of ZIF-90 particles.

Figure 7. Permeability-selectivity upper bound plot for ZIF-90/6FDA-TP composite films at different loadings for H2/CH4. The dashed curve indicates Maxwell model prediction.

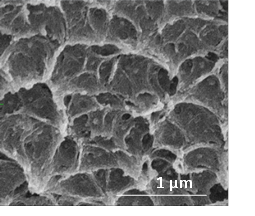

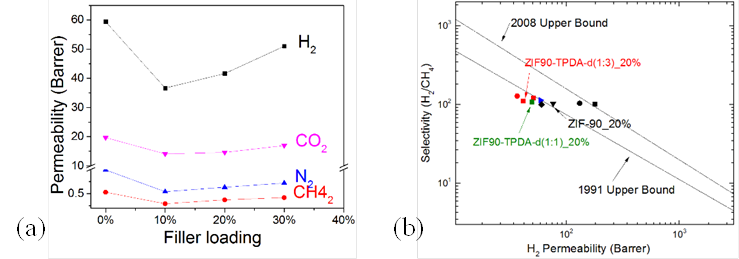

Composite membranes containing TPDA-d grafted ZIF-90 nanoparticles were also prepared to investigate how surface grafting affects the interface morphology and transport properties. SEM image (Figure 8) shows tight contact between the filler particles and the polymer matrix due to the strong supramolecular interactions between triptycene units as expected. Due to this strong polymer-filler interaction that possibly is accompanied with pore blockage, the composite membranes showed reduced gas permeabilities yet relatively constant selectivities compared to the pure polymer (Figure 9). The ZIF-90 particles with lower grafting density (ZIF-TPDA-d(1:1)) exhibited slightly higher permeability than the fully grafted one (ZIF-TPDA-d(1:3)) suggesting possible pore blockage when grafting density is high.

Figure 8. SEM image of composite membrane with 20 wt% of TPDA-d grafted ZIF-90 nanoparticles.

Figure 9. (a) Gas permeabilities as a function of filler loading and (b) H2/CH4 Robeson upper bound plot for composite membranes with modified ZIF-90 particles.

Ongoing and future work includes surface grafting ZIF-90 particles with longer “arm” to mitigate pore blockage and the preparation of composite membranes from (modified) single-wall carbon nanotubes and triptycene-containing polyimides.