AmericanChemicalSociety.com

Reports: B9 47193-B9: Simulation and Experimental Investigation of Energy Losses in Dividing Flow

Evan C. Lemley, University of Central Oklahoma

Introduction

This project involves experiments and simulations to determine energy loss coefficients of laminar flow in arbitrary geometry junctions as shown in Fig. 1. Research to determine flow characteristics in arbitrary junctions is an important but missing piece of engineering science data in the literature. The focus in the last year was refinement of an experimental system built in the previous grant periods, measurement of loss coefficients, and simulation of flow in junctions that matched exact experimental conditions. Two other achievements have been made as well: the automated simulation system that was built as part of the grant was used to throughly investigate dependence of junction loss coefficients on Reynolds number (VD/); and two students were able to obtain micro-scale versions of junctions and run experiments to determine loss coefficients at the microscale.

Milliscale System Experiments

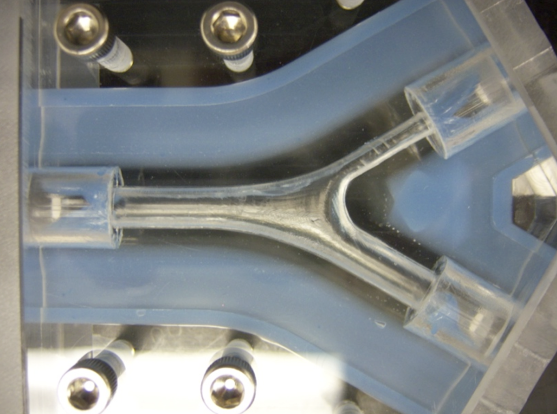

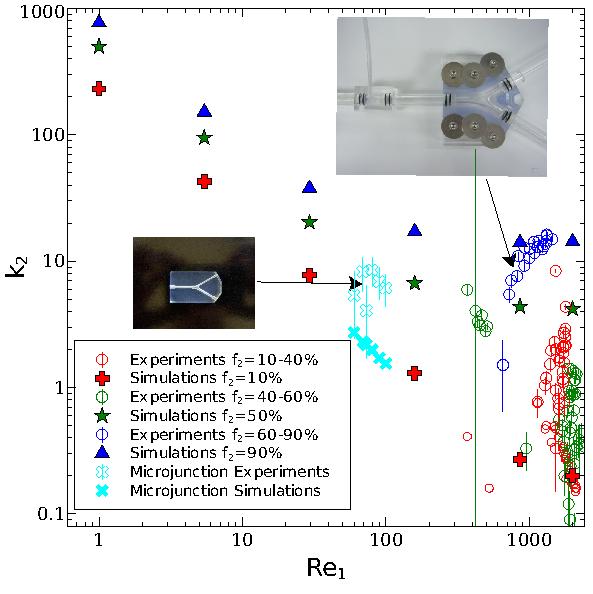

The milliscale (named this since the junctions tested with this system are millimeters in diameter) experimental system hardware (shown in Fig. 2) for loss coefficient measurement is a custom made flow system with capability to maintain constant pressure and flow conditions to junction test sections (as shown in Fig. 3) as well as provide data acquisition of pressure losses and flow rates. Procedures for system use, calibration of pressure sensors, error analysis of results, and training of students to use the system were all performed in year three. These accomplishments allowed the group to publish data for loss coefficients as a function of Reynolds number for a particular junction. These results were presented in August 2010 at an international conference on fluids engineering. Simulations matching experimental conditions were run and similar results for loss coefficients were obtained. These results are presented in summary form in Fig. 4. The measurements made with this system were made for a junction with an inlet diameter, d1, of 6.35 mm.

Microscale Junction Experiments

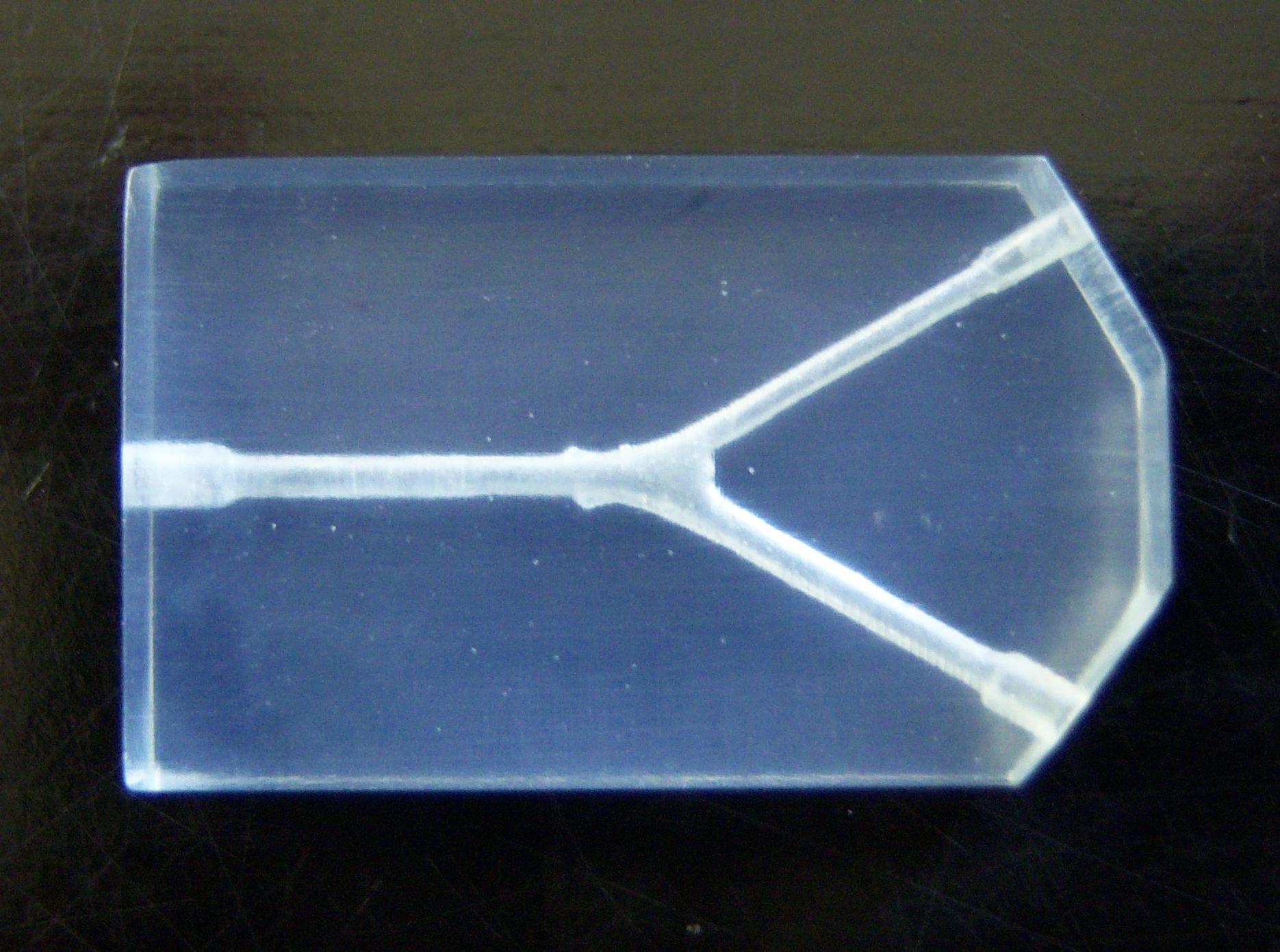

Additional experiments were carried out for a junction at the microscale by two students working on the larger junctions. This related project served as the student's senior engineering design project. The microjunctions were made using stereo lithography, but the geometries were generated by the same automated system that makes computational models for simulations and the larger milliscale experiments. An example of the a microjunction is shown in Fig. 5. A system was constructed including a syringe pump and the data acquisition system from the milliscale system was used to measure loss coefficients for the microjunction pictured in Fig. 5. The microjunction with mixtures of glycerin and water allowed experiments to be performed at smaller Reynolds numbers than the milliscale system. Some results for the microjunction are shown in Fig. 4 with the the milliscale results. Note that the geometry of the microscale and milliscale junctions are slightly different. Simulations run at the same conditions as the microscale experiments (also shown in Fig. 4) show good agreement with the experimental results. The results of the microscale junction experiments is yet to be published, but with some additional data and system refinement these results will be presented and published.

Tee and Wye Simulations to Determine Reynolds Number Dependence

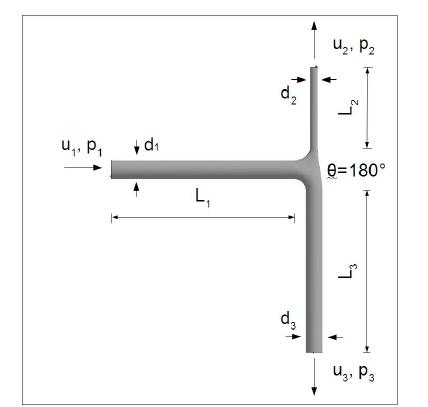

A number of simulations of laminar junction flow were performed for a tee (as shown in Fig. 6) and wye geometry to assess the effect of Reynolds number on the loss coefficient. These results were presented at an international conference in August 2010. A sample plot of results for a tee are shown in Fig. 7. Note the loss coefficient can be very large for Reynolds numbers of 10 or less, which is the flow regime that often exists in porous media and in microfluidic devices. These large relative losses may be important in understanding flow in porous media networks and in microfluidic devices. Also our work indicates that the effects of the disturbance of a junction persist far downstream of the junction. This persistence leads to the new consideration that a system of bends and junctions in a flow network may need to be considered as a whole and may not be combined as individual loss coefficients to determine flow and pressure effects.

Future and Ongoing Work

The following are related projects that have support and on which students are currently working

Simulations and experiments are continuing for both milliscale and microscale junctions to measure loss coefficients at intermediate Reynolds numbers (100 -- 1000).

Large scale "simple" simulations of networks of junctions to model porous networks

Experiments to measure flow through networks of microscale junctions.

Measurements of pressure losses of liquids in microchannels less than 25 microns.

Biomedical applications of junction pressure losses and junction networks.

Simulation of flow in combining flow (as opposed to dividing flow) in a tee.

Support for some of these projects is from the UCO Office of Research and Grants. Also I have submitted two NSF grant proposals in the last 14 months to extend our research of flow in junctions and junction networks by performing Particle Image Velocimetry. These have been declined to date, but I plan to resubmit as soon as possible.

Copyright © American Chemical Society