AmericanChemicalSociety.com

Reports: G10 47721-G10: Advanced Transparent Conducting Materials for Thin Film Solar Cells

Brady Gibbons, Oregon State University

As photovoltaic (PV) technology continues to mature, research beyond the active PV material is becoming more critical. One such area involves transparent conducting (TC) materials. TC's are an integral part of a solar cell. More and more, as the basic materials science issues are solved for the active PV materials, higher demands are placed upon the associated materials. TC's are no exception. The most common material, tin-doped indium oxide, is no longer the ‘best' material for a given solar cell. The demands on TC's have increased beyond conductivity and transparency alone. And, with the exceedingly high cost and demand of indium, the PV community is in desperate need of a functional replacement. This program was designed to explore a suite of material systems suitable for replacing current TC materials. New and existing compositions were to be investigated and implemented on the basis of transparency, conductivity, resistance to diffusion, thermal and chemical stability, and microstructure. At the conclusion of last year we reported on infrastructure development and initial TC thin film results. This year efforts continued regarding equipment development and TC research. However, late in 2009 a discovery at Oregon State resulted in an addition to our research focus aligned with this program. Along with our ongoing research on TC materials, we have developed a program for discovery of new materials used in high energy density electric storage for renewable energy and transportation applications.

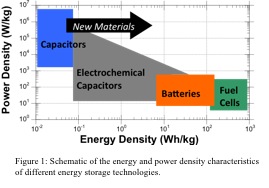

Many emerging technologies have electrical energy storage requirements that are not met by existing materials. This includes devices over many scales, from those that power portable or micro-flight systems, to electric-powered vehicles, to high power devices active on the electrical grid. Dielectric-based capacitors store charge through electronic polarization which leads to high power densities and fast discharge times, however energy densities are generally limited (as shown in Fig. 1). Electrochemical-based capacitors have shown progress utilizing a hybrid approach, however increased power densities usually come at the expense of a reduction in energy density and vice versa. Our added research focus is on the discovery and development of new dielectric materials capable of exhibiting electrical energy storage density of 100 Joules per cubic centimeter (a range previously inaccessible to dielectric capacitors). The research involves a new family of perovskite compositions that exhibit a high dielectric permittivity that persists to high electric fields: the Bi(Zn1/2Ti1/2)O3 --BaTiO3 perovskite solid solution.

Materials development on both research fronts is being undertaken in deposition systems constructed in large part with funds from this program. rf-magnetron sputtering is being used for TC development (and implementation in other collaborative work) and ozone-assisted pulsed laser deposition (PLD) along with rf-sputtering are being used for high energy density materials discovery. As described in last year's report, these deposition systems continue to significantly impact our research group via increased collaboration across our campus and with other institutions. This is an area of critical importance to the future of research in my group and the development of follow-on funding.

Figure 2 is an example of a multilayer structure of ZnO/CuO used to examine the diffusion resistance of ZnO and doped-ZnO. Microprobe analysis and spectroscopic ellipsometry are two representative techniques used to characterize these systems for microstructural stability as a function of process conditions. New high energy density thin film materials based on Bi-perovskite solid solutions have been developed with storage capabilities of up to 7 J/cm^3. Further increases are expected as structure-process-property relationships are elucidated.

From an educational perspective this program has also had an impact. In the spring of 2007 we introduced a new course -- "Experimental Techniques in Materials Science." This is a laboratory class, with modules designed to introduce students to various methods of fabrication and characterization of materials. Each offering is designed around a specific material. In 2007 and 2009 the focus was tin-doped indium oxide (the transparent conductor ITO). Both physical vapor and chemical solution deposition methods for ITO in our laboratory were extended to this class, and students were able to understand the importance of transparent conducting materials (no funds were directly used for the class).

As the end of the program approaches, I feel very strongly that the support of the PRF has been absolutely critical to my research group's success and growth. The infrastructure development has allowed us to move forward with numerous (successful and not) proposal opportunities. TC and high energy density storage materials research will remain a focus of our efforts for years to come.

Copyright © American Chemical Society