AmericanChemicalSociety.com

Reports: AC9 47976-AC9: Liquid Crystalline Membranes for Olefin/Paraffin Separations

Stephen M. Martin, Virginia Polytechnic Institute and State University and Eva Marand, Virginia Polytechnic Institute and State University

We are developing liquid crystal (LC) and liquid crystal polymer (LCP) based membranes which have selectivity targeted for olefin/paraffin separations using structural regularity and specific molecular interactions. The primary challenges being addressed include (1) the controlled fabrication of stable, defect-free membranes and characterization of the resulting liquid crystalline order, and (2) the characterization of transport properties and selectivities for an olefin/paraffin gas pair, in this case propane/propylene, as a function of liquid crystalline order and molecular structure. The goal is to enhance solubility and diffusion of the targeted molecules by enhancing molecular interactions and the ability of the gas component to fit into the liquid crystalline structure. <>2 Research Impact <>2.1 Supported Liquid Crystal Membranes:

Fabrication of Supported LC Membranes: Membranes consisting of a porous support impregnated with an LC material have proven useful in the evaluation of LC transport properties in solution-based separations. LC embedded membranes are prepared by impregnating the porous cellulose nitrate membrane with an LC material, such as 4-cyano-4'-octylbiphenyl (8CB) via vacuum filtration

Transport in Supported LC Membranes: A constant volume/variable pressure apparatus was used for transport property measurement. Under testing, the liquid crystals separated from the support. This was due to the increase of pressure (1.5–2.0 atm) on the feed side, which overcomes the capillary forces keeping the LC material in the porous support. For this reason, we concentrated on developing more physically robust membrane systems, such as polymer dispersed LCs (PDLCs.) <>2.2 Polymer-dispersed Liquid Crystal Membranes:

Figure 1: SEM images of the cross-section of a 55wt% 8CB/polysulfone.

Polymer-dispersed Liquid Crystal

(PDLC) Membranes: PDLC membranes

are phase-separated structures consisting of pockets of the LC material

dispersed in a polymer matrix (Figure 1.) As a result, they are more stable to applied

pressure than the supported LC membranes. A polysulfone/LC mixture is dissolved

in chloroform and cast on a glass substrate. The size and number of domains in

the membrane can be controlled via a temperature annealing step. At high

concentrations, the LC forms of separate macroscopic nematic and polymer

domains which lead to decreased membrane stability.

Transport in Polymer-dispersed

Liquid Crystal (PDLC) Membranes: We measured the permeation of propane

and propylene in pure polysulfone, and 8CB/polysulfone PDLC membranes (Table 1.) The data indicate some improvement in selectivity;

however, these membranes exhibit poor physical stability.

Table 1: Permeability and

selectivity for PDLC membranes produced using 8CB and polysulfone.

Permeability (barrers) 37 oC 50 oC Pure Polysulfone 6.4E6* 3.3E5* 34 wt% 8CB in PS 1.8E3 1.9E5 55 wt% 8CB in PS 2.0E3 4.6E3

Selectivity 37 oC 50 oC Pure Polysulfone 1.2 1.2 35 wt% 8CB in PS 2.1 1.1 55 wt% 8CB in PS 4.4 4.3

<>2.3 Side-chain

Mesogenic Polymer Membranes:

Materials and Fabrication: We

obtained a butadiene based side-chain polymer from the Institute of Macromolecular

Physics, Academy of Sciences of the Czech Republic. The polymer contained a cyanobiphenyl mesogen

and a six carbon spacer (Figure 3). The telechelic poly(butadiene)diol backbone

had an average molecular weight of approximately 2800 Da with 88 mol% mesogen

functionalization. With such a high degree of functionalization, the polymer

did not exhibit a liquid crystalline phase. We used an impregnation method to

fabricate the membranes in a porous support.

DSC indicated all transition temperatures were identical to the pure

polymer. SEM images confirm complete impregnation of the material in the

support.

Figure

3: Polymer structure of the butadiene backbone and cyanobiphenyl based

side-chains.

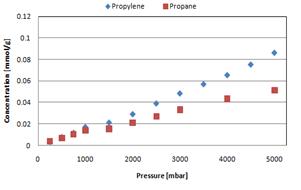

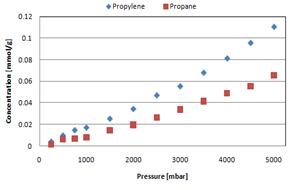

Transport in

Side-chain Polymer Membranes: Figure 5: Single gas propylene and propane sorption (left) 35 °C

and (right) 50 °C.

Sorption isotherms of propane and

propylene indicated a sorption selectivity of ~2 that remained constant when

varying both pressure and temperature. Gas

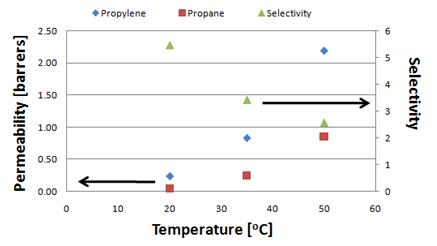

sorption increased with temperature. Permeability measurements for membrane

transport of both single and mixed gases were performed using a constant

volume-variable pressure and constant pressure-variable volume apparatus. Permeation measurements at room temperature,

the lowest temperature studied, exhibited the greatest permselectivity (Figure

6.) Permeation of both propylene and

propane increased with temperature.

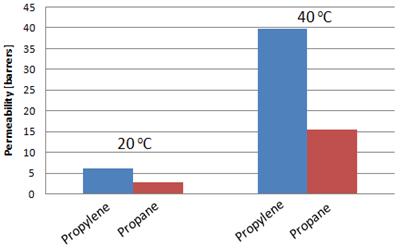

Figure 6: Single gas propylene and propane permeability and

selectivities.

Mixed gas permeability

measurements indicate that the permeabilities of both propylene and propane

increase with temperature, with no decrease in selectivity (Figure 7.) Overall permeability increased and

selectivity decreased slightly compared to single gas measurements. The

permeability and selectivity in the side-chain crystalline polymer are

promising, and we intend to study related polymers with lower fractions of

mesogen functionality in which liquid crystalline phases are observed. In the interim, we pursued the possibility of

inducing LC phases by blending the crystalline polymer with structurally

homologous small molecule liquid crystals.

Figure

7: Mixed gas 50/50 propylene/propane permeability results in BCP membranes

at 20 °C

and 40 °C. 3

Blended Polymer/Liquid Crystal Membranes:

Due to the lack of an LC phase

due to the high degree of functionalization, we have begun blending a small molecule

thermotropic liquid crystal with the polymer. The addition of a small organic

molecule should serve to plasticize the crystalline polymer, leading to an

increase in mobility and permeability and a possible LC phase. DSC measurements

indicate decreased melting temperature with added 8CB. Permeation of propylene in a 10wt% 8CB

membrane increased by a factor of 6 with only a slight reduction of selectivity

compared to the pure polymer membrane. 4

Career Impact:

The work has provided support for

one graduate student early in his PhD career and one graduate student at the

end of his PhD career. They developed expertise in membrane fabrication and

characterization (microscopy, SEM), transport property measurement, and has

gained experience in the design, fabrication, and modification of laboratory

instrumentation. In addition, the graduate student has been mentoring an

undergraduate researcher, providing valuable lab experience for the

undergraduate student and leadership experience for the graduate student. The

project has had a significant impact on the career development of Dr. Martin,

as it has allowed him to develop expertise and instrumentation in membrane

characterization and to begin exploring the area of mixed matrix (PDLC,) liquid

crystal polymer (LCP,) and blended LC/polymer membranes.

Copyright © American Chemical Society