AmericanChemicalSociety.com

Reports: UR10 50070-UR10: Controlling Morphology in Bulk Heterojunction Solar Cells via Chemical Design and Surface Patterning Methods

Lee Y. Park, PhD, Williams College

The ability to harvest more solar energy more efficiently (in terms of overall cost-of-implementation as well as quantum efficiency) is a critical challenge facing the scientific community. The development of organic solar cells promises to address several of the disadvantages of traditional solid-state based technologies. In particular, these offer the possibility of tailoring the absorption spectrum of the component materials, and of solution-processing light-weight, flexible, large area devices at low cost.

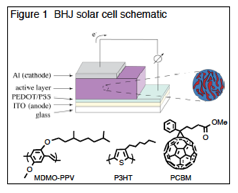

The

details of the micro- and nanoscale morphology that develop in polymer blend

films used in organic photovoltaic (bulk heterojuncction) devices play a

critical role in their performance. A schematic diagram of a BHJ solar cell is

shown in Figure 1. The "active

layer" is composed of a thin (~100 nm) phase-separated film of an electron

donating species (a soluble semiconducting polymer such as a PPV with a soluble

electron accepting species such as PCBM. Upon absorption of a photon, an exciton

is created which can then migrate within the film. At interfaces between donor and acceptor domains, the

exciton is separated into free holes and electrons. Under the influence of the inherent bias in the device

(created by the different conductive materials used as electrodes), these free

carriers can then travel to their respective electrodes. The details of the

microscopic phase separation that arises between the interpenetrating donor

(polymer) and acceptor (PCBM) networks in these films play a critical role in

device performance. The ideal

architecture is one in which light is absorbed efficiently, while at the same

time opportunities for exciton and free carrier recombination or annihilation

are minimized, thereby simultaneously optimizing charge generation, separation,

transport, and collection. Various

length scales are believed to be important in optimizing these different

aspects of device performance.

Optimal light absorption requires a polymer layer on the order of at

least 100 nm, while efficient charge separation requires a high interfacial

area between the donor and acceptor components, ideally with domain sizes comparable

to the exciton diffusion length (~10 nm) in order to minimize exciton recombination.

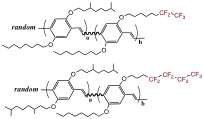

The most significant advances in performance achieved for these Our work thus far

has focused on the synthesis of new polyphenylenevinylene (PPV) type materials

containing fluorocarbon side chains.

We prepare our polymers via the commonly used base-catalyzed GILCH

polymerization (which gives rise to high MW PPVs), and have succeeded in

preparing a variety of new fluorocarbon-containing PPVs. Because of solubility

constraints encountered with these materials, we have thus far concentrated our

efforts on a series of random copolymers (of varying composition) of our

fluorinated monomers We have also begun investigating a

variety of possible strategies that might lead us to "blocky" copolymers. First, by starting with oligomers of

PPV as the monomers for the GILCH polymerization, we may be able to access

structures that have enough block-like character to further enhance the kind of

phase separation that is our goal.

Another possibility involves copolymerizations of GILCH monomers of

different reactivities as a means of preparing gradient polymers.

Finally, we have

also begun preliminary characterization of diode and photovoltaic behavior of

our fluorinated polymers, and are exploring the effect of different surface

chemistries on the transport properties of our polymer films.

devices

in recent years are attributable to improvements in domain size and ordering

within domains. We are interested in exploring the use of

fluorocarbon-hydrocarbon interactions as a means of guiding and driving

organization and domain size within the active layer of this type of solar

cell.

devices

in recent years are attributable to improvements in domain size and ordering

within domains. We are interested in exploring the use of

fluorocarbon-hydrocarbon interactions as a means of guiding and driving

organization and domain size within the active layer of this type of solar

cell.

with

hydrocarbon analogs as illustrated here.

(Because the GILCH route is not a well-controlled polymerization, block

copolymers are unfortunately not accessible, as is typically the case for

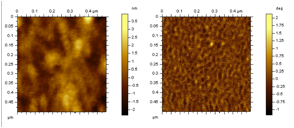

conjugated polymers.) Initial AFM

studies of these copolymers indicate that we may already be achieving enough

"blockiness" in our random copolymers to give rise to some phase

segregation. AFM images of thin

films one example of such a random copolymer are shown below: the films exhibit

a fine structure in the phase image (on the right) that is not

with

hydrocarbon analogs as illustrated here.

(Because the GILCH route is not a well-controlled polymerization, block

copolymers are unfortunately not accessible, as is typically the case for

conjugated polymers.) Initial AFM

studies of these copolymers indicate that we may already be achieving enough

"blockiness" in our random copolymers to give rise to some phase

segregation. AFM images of thin

films one example of such a random copolymer are shown below: the films exhibit

a fine structure in the phase image (on the right) that is not  visible

in the height image (on the left) that we attribute to some degree of

microphase segregation. In

addition, these materials exhibit an enhanced fluorescence (as compared with

hydrocarbon analogs) particularly in the solid state, further suggesting that

inclusion of the fluorinated side chains results in some form of enhanced

ordering.

visible

in the height image (on the left) that we attribute to some degree of

microphase segregation. In

addition, these materials exhibit an enhanced fluorescence (as compared with

hydrocarbon analogs) particularly in the solid state, further suggesting that

inclusion of the fluorinated side chains results in some form of enhanced

ordering.

Copyright © American Chemical Society