Back to Table of Contents

43857-AC9

An Integrated Numerical and Experimental Study of Scaling Effects in Stirred Tank Reactors

David F. Hill, Pennsylvania State University

An Integrated

Numerical and Experimental Study

of Scaling Effects in Stirred Tank Reactors

Second Year

Report

Overview

This project

proposed to conduct an integrated numerical and experimental study of

the

turbulent flow in stirred tank reactors.

These flows are widely used in the chemical, petroleum, and

environmental engineering industries.

Knowledge of the mean and turbulent velocity fields in these

flows is

important as the large and small scale flow structures help to control

reaction

and blending rates. The work was

motivated by the need to be able to scale up small laboratory-scale

experimental results to full prototype scale.

Presently, the literature contains many experimental studies of

these

flows. Aggregated together, the studies

span a modest range of physical scale and operating conditions. Individually, however, the studies are

individually

quite limited in terms of the range of parameter space covered. As a result of differences in experimental

configuration from one study to the next, which lead to differences in

derived

results, it is difficult to arrive at any substantive overall

conclusions about

the scaling of the flow field. The

funded project sought to conduct the most extensive set of scaling

experiments

to date. In addition, computation

simulations of the flow, using the experimental results, were performed.

Project

Management

The funded

project

spans a period of two years, which ended in August 2008, with an

unfunded

extension presently ongoing. The first

year was conducted at the Pennsylvania

State University,

under the direction of Dr. D. Hill. The

second year was conducted at the University of Florida,

under the

direction of Dr. S. Balachandar.

Work

Accomplished

- We have

completed our experimental work on the geometric and Reynolds number

scaling. Regarding the Reynolds number

scaling, we have found that the mean velocity fields collapse well over

a wide range of Re, as expected. The

turbulent velocity fields were found to approach Re invariance for

values of Re > 100,000. Regarding the

geometric scaling, we found that the scaled results from the four

differently sized experimental facilities did not collapse well,

despite the extraordinary care taken to ensure exact geometric

similarity in the facilities. This

relative lack of agreement was found both in the mean and in the

turbulent velocity fields.

- We performed

extremely unique volumetric three-component (V3V) particle image velocimetry (PIV) measurements in our

experimental facility. This technique is

able to measure the instantaneous velocity field over a finite

three-dimensional volume, yielding an extremely dense grid of velocity

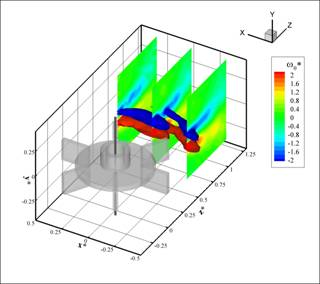

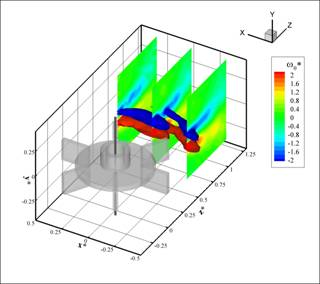

data. As Fig. 1 shows, these measurements

allow, for the first time, the instantaneous visualization of the

vortex pairs that are shed by the blade tips and that are responsible

for the mixing in the tank.

Figure SEQ Figure \* ARABIC 1: Isosurfaces

(and slices) of vorticity, illustrating

the vortices

shed by the blade tips.

- We have

developed a versatile finite volume code that uses an immersed boundary

(IB) technique. This code has several

attractive features that make it suitable for the investigation of

complex geometries, such as the mixing tank, as in the present case. We have conducted several direct numerical

simulations to study the applicability of the code to present problem

of a mixing tank with Rushton impellers. During the ongoing unfunded extension of this

project, we are actively working to make the code meet our final goal,

which is to simulate a wide array of cases and find out the physical

understanding for high Re turbulent flow in a mixing tank. The improvements we are pursing include the use of Large

Eddy Simulations (LES), fully parallelized MPI (message passing

interface), scalar mixing, and the direct integration of the numerical

and experimental results.

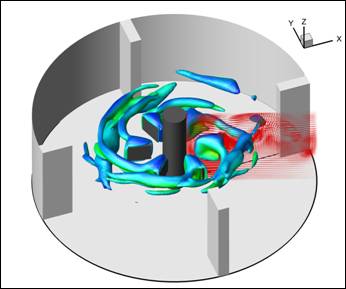

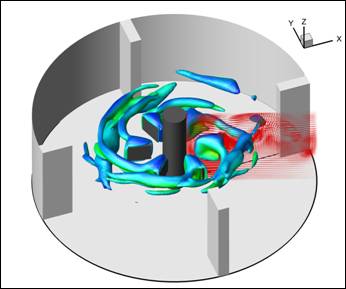

Figure SEQ Figure \* ARABIC 2: Numerical simulation of the

flow in a

cylindrical tank stirred by a Rushton

turbine.

Project

Deliverables, Presentations, and Publications

- Hill, D.F., Troolin, D., Walters, G., Lai, W., Sharp, K.V.,

2008, “Volumetric three component velocimetry

measurements of the turbulent flow in stirred tank reactors,” 14th International Symposium on Applications of Laser

Techniques to Fluid Mechanics, July 7-10, Lisbon, Portugal.

- Sharp, K.V.,

Hill, D.F., Troolin, D., Walters, G., Lai,

W., 2008, "Volumetric 3-component velocimetry

(V3V) measurements of the turbulent flow in stirred tank reactors," Experiments in Fluids, submitted.

- Walters, G.,

2008, “An investigation of geometric scaling of mean and turbulent

flows in cylindrical stirred tank reactors,” The Pennsylvania State University,

M.S. Thesis.

- Vergara, A.,

Hill, D.F., 2008, “Destratification by mechanical mixers: mixing

efficiency and flow scaling,” Penn State College of

Engineering Research Symposium, April, University Park, PA.

- Walters, G.,

Hill, D.F., 2008, “An investigation of geometric scaling of mean and

turbulent flows in cylindrical stirred tank reactors,” Penn State

College of Engineering Research Symposium, April, University Park, PA.

In addition

to these, the PIs are presently

drafting additional manuscripts for submission in 2009.

Back to top