Back to Table of Contents

46326-AC10

Surface Enhanced Fluorescence in Polymer Semiconductors

Sue Carter, University of California, Santa Cruz

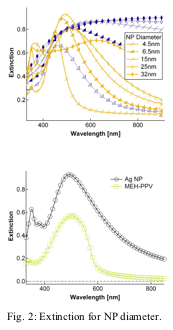

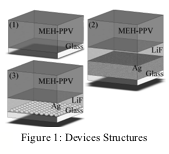

Figure 1: Devices Structures |

Our

research focused on understanding surface enhanced fluorescence in thin films

of polymer semiconductor poly[2-methoxy-5-(2'-ethylhexyloxy)-p-phenylene

vinylene] (MEH-PPV). Three

different types of device structures were created as shown in Figure 1,

consisting of (1) polymer film alone, (2) with Ag mirror, and (3) with Ag

nanoparticles (NP). For the NP devices, the Ag films were annealed in air using

a four stage anneal process to allow the particles to coalesce from varied

morphologies to a film of spheroids with minimal dispersion of diameters. The

LiF was then deposited by thermal evaporation before a spun cast thin film of

MEH-PPV completed the device structure.

The Ag deposition ranged from 5 nm to 25 nm, the LiF film thickness was

varied from 5 nm to 110 nm, and the thickness of the MEH-PPV was constant at 40

nm. Several data acquisitions were

performed at different sample orientations with several samples to check for

variation and ensure uniformity.

Our

research focused on understanding surface enhanced fluorescence in thin films

of polymer semiconductor poly[2-methoxy-5-(2'-ethylhexyloxy)-p-phenylene

vinylene] (MEH-PPV). Three

different types of device structures were created as shown in Figure 1,

consisting of (1) polymer film alone, (2) with Ag mirror, and (3) with Ag

nanoparticles (NP). For the NP devices, the Ag films were annealed in air using

a four stage anneal process to allow the particles to coalesce from varied

morphologies to a film of spheroids with minimal dispersion of diameters. The

LiF was then deposited by thermal evaporation before a spun cast thin film of

MEH-PPV completed the device structure.

The Ag deposition ranged from 5 nm to 25 nm, the LiF film thickness was

varied from 5 nm to 110 nm, and the thickness of the MEH-PPV was constant at 40

nm. Several data acquisitions were

performed at different sample orientations with several samples to check for

variation and ensure uniformity.

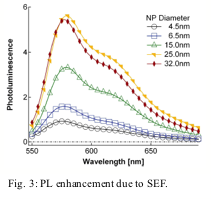

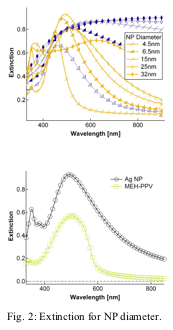

Fig. 2: Extinction for NP diameter. |

Electromagnetic

theory shows that the frequency of the surface plasmon resonance has a

dependence on the diameter, ellipticity, density, and dielectric properties of

the surrounding medium and the NP itself. To

achieve a surface plasmon peak resonance that matches the MEH-PPV peak

absorption (490 nm), Ag deposition was varied from 5 nm to 25 nm in 5 nm

increments. Annealing of the Ag layer resulted in a nanoparticle (NP) layer

that was a uniform dense layer of Ag NPs with resonance peaks varying about the

MEH-PPV absorption peak. Surface

analysis showed the RMS surface roughness to be an accurate estimation of

particle diameter and the average measured width of particles show elliptical

spheroidal characteristics with aspect ratios around 1:7, which is advantageous

for SP excitation.

The

extinction of the Ag layer changes with evaporation thickness and anneal as

shown in Figure 2(a). The blue curves show the extinction of the deposited Ag

layers whereas the orange curves show the extinction of the Ag layers after

formation of the NP layer. Upon annealing the particles making up the Ag layer

become more uniform and the surface plasmon peak tightens. For larger

thicknesses no surface plasmon peak is seen pre-anneal and an approach of the

bulk dielectric properties is observed and a shift toward larger wavelength

resonances is seen after anneal. For a maximum enhancement, the extinction peak

of the Ag NP layer and the peak absorption of MEH-PPV should be matched,as

shown in Fig. Figure 2(b).

With the introduction of Ag NP in close

proximity of the photoactive polymer, we observe large enhancements in PL. With

a small 5 nm shift in peak PL emission wavelength, the resulting enhancement

above the maximum PL of the control can be larger than a factor of 3 at the

absorption peak of MEH-PPV with out much parameter tuning for optimization

(Figure 4). In contrast, there is an overall reduction in PL for Ag mirrored

devices. This strongly suggests that the SP play a critical role in the PL

enhancement seen in the near-field region.

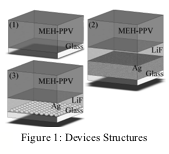

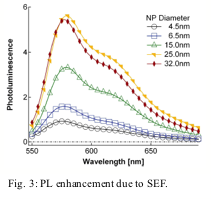

Fig. 3: PL enhancement due to SEF. |

Figure

3 shows the PL of Ag nanoparticle devices for different Ag evaporation

thicknesses, and a fixed LiF spacer thickness of 20 nm. A general increase in

PL is seen for thicker layers (NP diameters) of Ag with the enhancements much

larger than the mirror control devices.

The peak in PL occurs for a 45 nm LiF thickness which is drastically

different than the surface plasmon enhanced PL in fluorescent dyes such as

rhodamine 6G where the canonical separation distance for dyes is ~4 nm. This

effect can be explained by the differences in the quenching distance dependence

between dyes and polymers. The distance range in which significant quenching in

dyes occurs extends out to 10 nm where

as in polymers the distances range out to 60 nm. So,

for polymers a larger separation distance is needed before maximum enhancement

takes place.

In

summary, our research shows that the PL of MEH-PPV in the presence of Ag NPs is

found to have enhancement for varying NP sizes and varying plasmon- polymer

separation distances. As we would expect within the near field optical range,

the difference in the mirrored and NP devices suggests that the large PL

enhancement is clearly not due to interference effects but may be due to a

superposition of effects including SP electric field enhancement and reflectivity

dependence on change in dielectric constant. Furthermore, we find that, because

polymers are more sensitive to PL quenching than the small molecule systems,

larger separation distances are required to achieve maximum PL enhancement.

Back to top

Our

research focused on understanding surface enhanced fluorescence in thin films

of polymer semiconductor poly[2-methoxy-5-(2'-ethylhexyloxy)-p-phenylene

vinylene] (MEH-PPV). Three

different types of device structures were created as shown in Figure 1,

consisting of (1) polymer film alone, (2) with Ag mirror, and (3) with Ag

nanoparticles (NP). For the NP devices, the Ag films were annealed in air using

a four stage anneal process to allow the particles to coalesce from varied

morphologies to a film of spheroids with minimal dispersion of diameters. The

LiF was then deposited by thermal evaporation before a spun cast thin film of

MEH-PPV completed the device structure.

The Ag deposition ranged from 5 nm to 25 nm, the LiF film thickness was

varied from 5 nm to 110 nm, and the thickness of the MEH-PPV was constant at 40

nm. Several data acquisitions were

performed at different sample orientations with several samples to check for

variation and ensure uniformity.

Our

research focused on understanding surface enhanced fluorescence in thin films

of polymer semiconductor poly[2-methoxy-5-(2'-ethylhexyloxy)-p-phenylene

vinylene] (MEH-PPV). Three

different types of device structures were created as shown in Figure 1,

consisting of (1) polymer film alone, (2) with Ag mirror, and (3) with Ag

nanoparticles (NP). For the NP devices, the Ag films were annealed in air using

a four stage anneal process to allow the particles to coalesce from varied

morphologies to a film of spheroids with minimal dispersion of diameters. The

LiF was then deposited by thermal evaporation before a spun cast thin film of

MEH-PPV completed the device structure.

The Ag deposition ranged from 5 nm to 25 nm, the LiF film thickness was

varied from 5 nm to 110 nm, and the thickness of the MEH-PPV was constant at 40

nm. Several data acquisitions were

performed at different sample orientations with several samples to check for

variation and ensure uniformity.