44857-AC9

Surface Deformation from Particle Impacts in a Liquid Environment

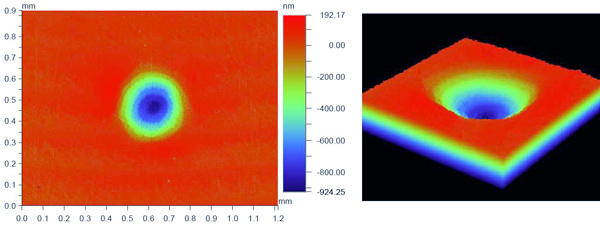

Fluid-particle flows encompass a diverse range of industrial and geophysical problems. In some applications, the particles impact the wall or bounding surface causing significant surface deformation. These erosion processes can affect equipment performance, as well as reducing reliability and operation life of piping and machinery. The research work at Caltech involved a series of experiments involving particle collisions with a ductile surface in a liquid environment. The goal of the work is to develop models of the collisional interactions of individual particles that can be incorporated into simulations of flows with many particles. The experiments have involved a range of impact conditions, material properties of the impacted surface, as well as fluid properties. The material properties of the particle and the sample allowed us to assume that the particle is rigid and does not deform plastically. The plastic deformation occurs only on the samples. All collisions were recorded with a high speed camera to determine the impact (Ui) and rebound particle (Ur) velocities. For the combination of materials used, the elastic limit was reached at relatively low speeds. The deformation produced by the collisions was analyzed using an optical profilometer. Since the deformations are small, the sample surfaces were polished and the resulting surface roughness was at least an order of magnitude less than the smallest indentation. An example of a crater resulting from particle impact is shown in the figure below. |

|

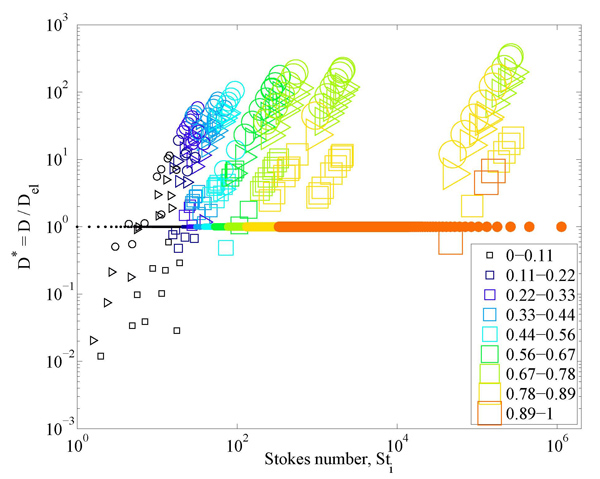

The crater resulting from a 0.013 m diameter steel sphere impacting an aluminum surface at a speed of 0.24 m/sec in a glycerol/water mixture. The resulting crater diameter is 400 µm with a depth of 0.92 µm and a surface roughness of 0.017 µm. Surprisingly, the measurements showed that the size of the indentations is independent of the properties of the surrounding fluid, and depends only on the impact velocity and material properties. The normal coefficient of restitution, however, is affected by the liquid lubrication between the colliding surfaces and the inelasticity. The collisional effects are characterized by the impact Stokes number (St=ρpUi/dµ) defined from the particle density (ρp), the impact velocity just prior to collision (Ui), the particle diameter (d), and the fluid dynamic viscosity (µ), and a deformation parameter, D*, which is a ratio of the kinetic energy of the impacting particle to the kinetic energy of a particle that would result in a plastic deformation. Hence, D* less than unity would denote completely elastic collisions; D* greater than one are inelastic. Lubrication effects are significant when St<1000. The experiments clearly show four different regimes depending on the impact Stokes number and a deformation parameter: lubrication and elastic deformation (St<1000 and D*<1); lubrication and elastic-plastic deformation (St<1000 and D*>1) ; elastic deformation with no hydrodynamic losses (St>1000 and D*<1) ; and elastic-plastic deformation with negligible lubrication effects (St>1000 and D*>1) . As shown in the figure below, the resulting coefficient of restitution (e=-Ur/Ui) depends on the magnitude of these two parameters. |

|

A regime map of the deformation parameter D* and impact Stokes number showing the variation in the coefficient of restitution (defined in terms of the rebound velocity normalized by the impact velocity). The symbol size and color correspond to the value of the coefficient of restitution. When the coefficient of restitution is small, all of the incoming kinetic energy is lost to either lubrication forces or plasticity effects. When the coefficient of restitution is close to one the particle rebounds at a speed nearly equal to the impact speed; the collision is nearly inelastic and lubrication effects are small. An analysis of the erosion of the ductile materials in a liquid environment was also performed. The size of the crater formed by the impact of a single particle against a ductile target can be estimated from theoretical calculations. The estimates of the size of the craters agree well with experimental measurements. |