44245-G10

Novel Boron-Based Nanomaterials for Thermoelectric Energy Conversion

During the period from September 1, 2007 to August 31, 2008, the following tasks have been completed.

Synthesis and characterization of alkaline-earth metal hexaboride (MB6, M=Sr, Ba) 1D nanostructures:

The MB6 1D nanostructures are appealing candidates for high temperature thermoelectric energy conversion. In last reporting period, catalyst-assisted growth of MB6 1D nanostructures was achieved by pyrolysis of B2H6 over alkaline-earth metal oxide (MO) or alkaline-earth metal carbonate (MCO3) powders at elevated temperature (~890-960 ºC) and low pressure (~165 mTorr). In this reporting period, more systematic work has been done to understand the growth mechanism of MB6 1D nanostructures. An untraditional vapor-liquid-solid growth mechanism was identified. A manuscript based on the finding from this project has been submitted to Chemistry of Materials, and is currently under revision.

Mechanical property study of alkaline-earth metal hexaboride (MB6, M=Sr, Ba) 1D nanostructures using:

The motivation of this part of work is to study the mechanical properties of boron-based 1D nanostructures. Good thermoelectric materials not only need to have remarkable thermoelectric figure of merit, but also need to be robust. Therefore, it is important to study their mechanical properties.

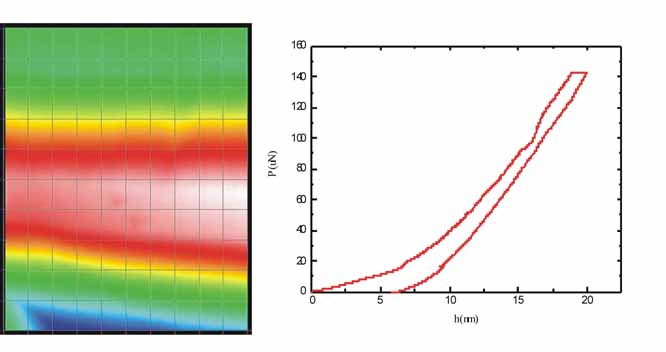

A MTS nanoindenter G200 with nano-vision option and continuous stiffness measurement option was used to image and indent the MB6 1D nanostructures. The two ends of each 1D nanostructure were fixed to the substrate by electron beam induced deposition (EBID) in a Scanning Electron Microscope (SEM). The indentation loading schedule was defined as: loading with a constant ratio of the loading rate to the current load of 0.05 s-1. A small sinusoidal force oscillation was superimposed on the quasistatic main loading schedule and the harmonic displacement amplitude was controlled to be a constant of 1.0 nm. Figure 1(left) shows the image of a BaB6 nanowire after two indentations. Figure 1(right) is one of the corresponding load vs displacement into surface curve. The Young's modulus of the nanowire is around 200 GPa based on standard Oliver-Pharr method. More accurate determination of Young's modulus is under way by incorporating the effect of substrate material.

Figure

1. (left) An image of

a BaB6 nanowire after indentations; (right) A load vs displacement into surface (P-h) curve on the BaB6

nanowire. The project “Design and Instrumentation of

a Micro-Compression Apparatus in a Scanning Electron Microscope” initiated in

last reporting period is still underway. The basic design has been finalized,

and the idea was presented in 2007 MRS fall meeting. The next step is to

machine the components and implement the apparatus.

Working together with a SRF fellow: The SRF fellow: Dr. Lei Zhang from Other important achievement: Based on the preliminary results obtained from this ACS PRF

Type G grant, the PI received two NSF grants. They are (1) CAREER: Boron-based

one-dimensional nanostructures for thermoelectric energy conversion; and (2)

Collaborative Research: Novel Boron-based One Dimensional Nanostructures:

Synthesis and Measurement of Transport Properties. In addition, a Ph.D. student

(Syed Amin) was graduated

in this reporting period. The student was supported by both the PI's start up account and the ACS PRF Type G Grant.