Back to Table of Contents

44743-B10

Glow-Discharge Plasma as a Synthetic Medium for Nanocrystalline Non-Molecular Metal Oxides

Richard W. Schaeffer, Messiah College

Introduction

The plasma synthesis

project has continued to build on the progress from 2006-2007, which improved the

plasma chamber design, added a second plasma chamber, and added a mass-flow

controller system to better regulate gas delivery to the plasma. During 2007-2008, we were able to synthesize

more than two dozen metal oxide films on glass and metal substrates. These films were characterized for

stoichiometry using atomic absorption spectroscopy, phase composition using powder

x-ray diffraction, and morphology using optical and atomic force microscopy.

The

Plasma Reactor and Associated Systems

We continued modifying the

shape and orientation of the reactant cathode and substrate this year. The hollow cathode design implimented last

year (using custom made glass sheaths to house the metal cathode) did not

resolve all of the problems associated with the plasma synthesis. Although, as reported last year, the hollow

cathode design resulted in a more spatially directed plasma, a more concentrated

deposition of product on the substrate, and improved product deposition rates,

we are still struggling with poor reproduciblity. We are successfully making metal and mixed

metal oxides, but product yields, stoichiometry, and morphology vary significantly

from sample to sample. We attempted to

exercise better control over the system by directing the plasma gas flow

through the cathode to promote a more uniform product formation in the plasma

and a more evenly and completely deposited product on the substrate, however,

improvements were not consistently realized.

We are currently working on another cathode design to address these

difficulties. The

enhancements to the plasma system made at the end of the last report period

have worked well. The electronic mass

flow control of the plasma gases, argon and oxygen, have vastly improved the

control and stability of the plasma gas composition and flow. The MKS

type M100B mass-flow controllers and M10MB mass-flow meters allow excellent

stability and reproducibility in both gas pressure, flow, and mixing. We are confident that the problems in product

formation (described above) are not derived from control over the plasma

gases. Moreover, we have been successful

in stabilizing the second plasma chamber so that it now behaves very

consistently like the first plasma system with respect to gas control and

voltage-current realtionships. Therefore

our continuing work will focus on redesigning the plasma cathode and substrate

to improve product yield, stoichiometry, and morphology.

Formation

and Characterization of Products

As mentioned

previously, we have made about two dozen different samples of metal oxides from

the plasma system over this reporting

period. As before, the products have

been analyzed for stoichiometry via atomic absorption spectroscopy, phase

composition via powder x-ray diffraction, and in several cases, morphology via optical

and atomic force microscopy. As reported in 2006-2007, products from the reaction

of a copper cathode in an oxygen plasma have shown a curiously wide ranging and

unusual elemental composition. This

reporting period values ranged from Cu(1.05)O to Cu(1.22)O

in an argon rich plasma (3:1 moles Ar to O2) to Cu(2.31)

to Cu(3.27)O in an oxygen rich plasma (3:1 moles O2 to

Ar). Again, the reproducibility of the

stoichiometry is not as good as desired, ranging between 10-30% rsd. Like past work, part of the difficulty has

been the small yield of product ranging from less than 1.00 to 2.14 mg for

24-48 hour run times. This increases the

relative uncertainty of stoichiometric determinations. We are hopeful that continued work on the cathode

design will lead to higher and more reproducible yields and more consistent and

predictible product stoichiometry. We

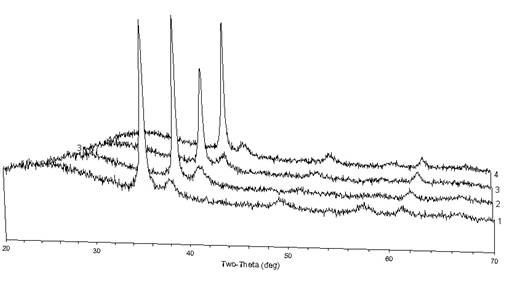

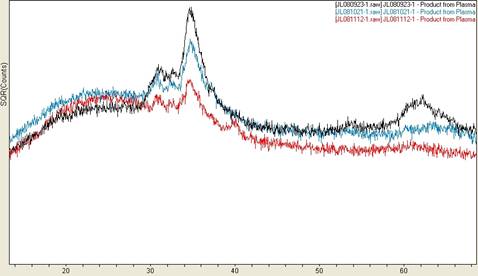

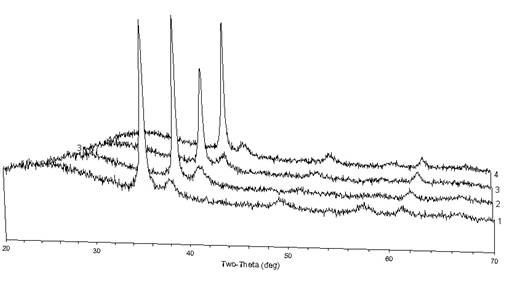

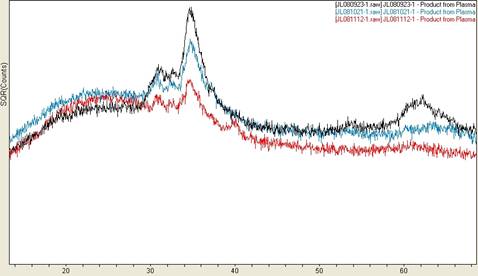

have analyzed many of the plasma products with powder x-ray diffraction, which typically

reveal a crystalline phase of CuO (tenorite) with varying peak profiles and an

amorphous phase as illustrated in Figure 1 and Figure 2. The variation in peak profile probably

represents differences in particle size and crystallinity. Finally, for many of

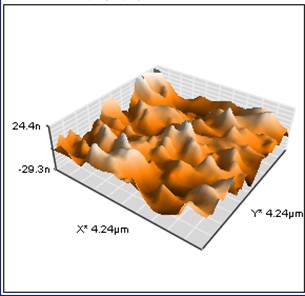

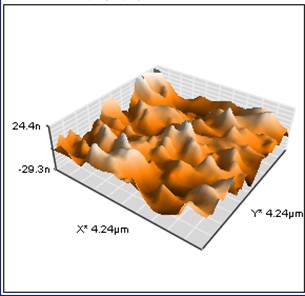

the samples, atomic force microscopy revealed

an uneven “mountain range” product morphology on the surface of the substrate as

illustrated in Figure 3. The height and diameter

of the individual “peaks” were about 50 and 400 nm, respectively.

Figure SEQ Figure \* ARABIC 1.

Powder XRD patterns from four product films from a plasma synthesis

with a copper hollow cathode design. The

peak 2θ positions are consistent with

CuO, but with apparently varying stoichiometry.

Figure 2. Powder XRD patterns

from four product films from a plasma synthesis

with a copper hollow cathode design. The

peak 2θ positions are consistent with

CuO, but with profiles that indicate smaller particle size or less

crystallinity.

Figure SEQ Figure \* ARABIC

3. Three

dimensional AFM image of CuO

plasma product.

Back to top