www.acsprf.org

Reports: DNI950554-DNI9: Gas Expanded Lubricants - Improving Energy Efficiency Using 'Smart' Fluids

Andres F. Clarens, PhD , University of Virginia

Building

the foundation of the chemical understanding necessary to selecting the proper

components and operating conditions is critical to delivering this technology

to the power generation industry. In order to develop this understanding, the

focus of this work is guided by two primary research objectives: (1) Characterize

the relationship between GEL composition and bulk properties and (2) Establish

the influence of GELs on gear behavior. In order to fulfill these objectives, two

principal research tasks have been defined. During the first year of the project period, significant progress has been

made in the development of both of these tasks, outlined below.

The work in this task is

focused on measuring three important chemical properties of binary CO2/lubricant

mixtures: 1) the diffusion of CO2 into the lubricant 2) the

oxidative stability of the mixtures and 3) the rheology of these mixtures under

elevated temperatures and pressures. The diffusivity is being measured using

custom built pressure vessels in which liquid and gas phase mixtures are

combined and the pressure is measured for 20-hours. The experiments are

performed in a temperature-controlled bath to minimize temperature fluctuation.

The pressure history is then fit to an analytical expression using a non-linear

regression tool to calculate constants for rate of change and equilibrium

pressure. Results indicate greater diffusivity of CO2 into the

lubricants with lower viscosities. A similar type of experimental setup is

being used to measure oxidative stability. A pressure vessel is fitted with a

two-way valve immediately above the CO2 intake to allow for

pressurization, isolation, and subsequent disconnection from the syringe pump

used to pressurize the vessels. For our purposes, oxidative degradation of

lubricant has its most important impact on the viscosity of the lubricants. After

allowing the mixtures to sit for 1-4 weeks at elevated temperatures, the lubricant

is degassed and the viscosity of the lubricant is measured. Oxidation of synthetic

lubricants generally results in decreased molecular weight and consequently

viscosity. The

viscosity of GELs under a variety of conditions is being characterized under

pressure using an Anton Paar MCR 301 rheometer equipped with a high-pressure

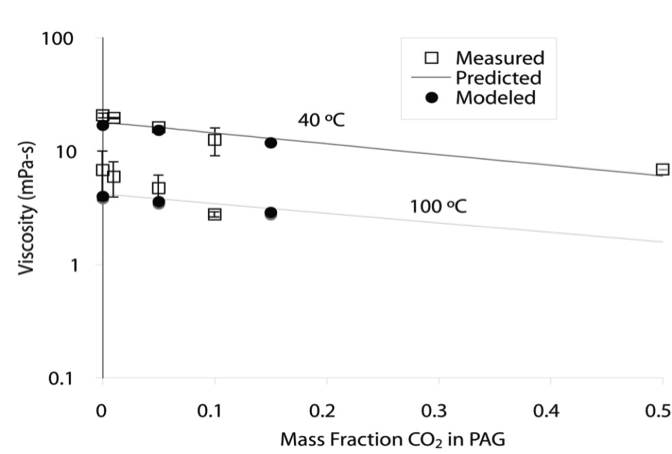

measuring cell rated up to 15 MPa. Figure 1 demonstrates the relationship

between the mass fraction of CO2 in the mixture and the viscosity.

The data shows a good fit with Equation 1. Mass fraction values were obtained

by extrapolating pressure-mass fraction data from previously published work. As

predicted, the viscosity of the GEL decreases logarithmically with increasing

mass fraction of CO2 according to equation 1: The

viscosity-composition data being generated here will form the cornerstone of

the controllers that will be developed to regulate the composition of the GELs

being delivered to the bearing. Figure 1. Viscosity of PAG-CO2

mixtures as a function of mixture composition at 40°C and 100°C. The results were

obtained experimentally while the predicted value is obtained using a

theoretical equation. The modeled values were used to develop modeling

estimates of power loss reductions in tilting pad journal bearings. Task 2. Develop an experimental testbed to measure

bearing performance using GELs A

major focus of the first year of the project has been to design the mechanical

test rig to be used to measure the performance of GELs in tilting pad bearings.

The test rig will utilize a 10 hp motor capable of reaching 10,000 rpm to drive

a 1.5" rotor of approximately 42" in length. This rotor will be supported by

two tilting-pad journal bearings supplied by Lufkin-RMT, Inc., who will also

finalize all designs for the test rig and manufacture the individual

components. This task was particularly challenging because custom bearing

housings had to be designed to ensure that they would be capable of reaching

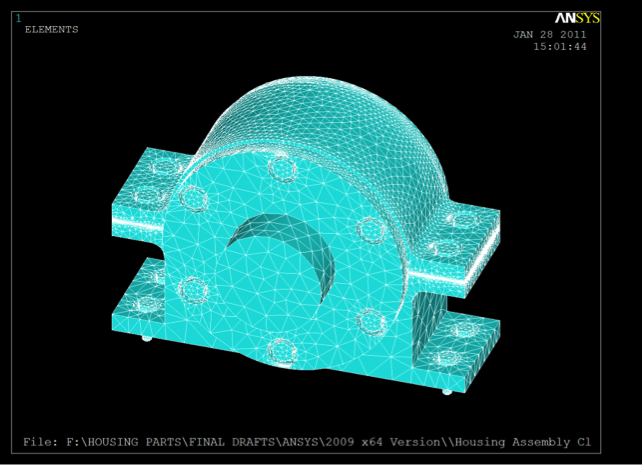

pressures of up to 17 MPa. A finite element analysis was used to optimize key

design parameters such as material selection and thickness, number and size of

bolts, and accommodations for seals, instrumentation, and lubricant inlets and

outlets. Figure 2 presents a rendering of the finite element model of the final

housing design. The

design of the oil seals was especially challenging because of the pressures and

speeds being used in this system. To meet these difficult conditions we maximized

the face area exposed to the pressure and utilizing a Teflon-coated steel

o-ring to allow the oil seal to form a tight seal without becoming overly rigid

and acting as a bearing, which would introduce forces that could cause the test

rig to become unstable. The final step in designing the GEL testbed was to

develop a GEL delivery system. That system has been designed and the

construction of the unit has been contracted out. All elements of the this test

rig are now in production and we expect the rig to be built by end of 2011. Figure 2. Finite element model used to

analyze the effects of high pressure on a bearing housing design.