www.acsprf.org

Reports: DNI1049903-DNI10: Nanoengineering Polymeric Membranes for Gas Separations and Proton Exchange

Rodney D. Priestley, PhD , Princeton University

Processing glassy polymeric membranes with enhanced thermal and kinetic stability

Rodney D. Priestley, Princeton University, ACS PRF 49903-DNI10

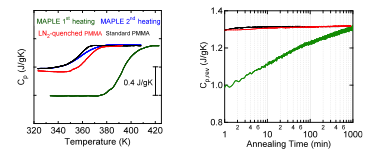

We have completed an investigation of the glass transition and stability of supported PMMA films deposited by MAPLE. A main result of this work, as illustrated in Figure 1 (left), is that, via MAPLE, we have been able to prepare films of PMMA that exhibit a remarkable enhancement in thermal stability (i.e., ~ 33 K increase in the glass transition temperature (Tg)) in comparison to ordinary PMMA. We have determined the importance of substrate temperature in the formation of stable, high Tg PMMA films when deposited at a constant deposition rate of ~ 0.25 nm/sec; films not deposited at ~ 0.85Tg exhibited large endothermic peaks during heating, an indication of glassy-state structural relaxation, i.e., instability. Furthermore, we have observed a dependence of deposition rate on the enhancement of thermal stability, i.e., a slower rate of deposition leads to a higher Tg. The results demonstrate, for the first time, the formation of a thermally stable polymer film by MAPLE. A second significant finding of this work, as illustrated in Figure 1(right), it that when isothermally annealed at Tg (Tg of the corresponding film), the time required for the glass to liquid transformation is ~ 2-orders-of-magnitude greater for MAPLE-deposited PMMA than ordinary PMMA.

Figure 1: Left) Heat capacity of ordinary and MAPLE-Deposited PMMA. Right) Reversing heat capacity of ordinary and MAPLE-Deposited PMMA as a function of time at Tg.

We have discovered that the enhancement in Tg of MAPLE-deposited glassy films is accompanied with a significantly reduced density compared to the standard glass. From refractive index (RI) measurements at room temperature, the densities of MAPLE-deposited and standard PMMA were determined to be 0.681 ± 0.008 g/cm3 and 1.184 ± 0.002 g/cm3, respectively. Hence, MAPLE-deposited PMMA can have an ~ 42 % reduced density, as estimated from RI measurements. This finding, i.e., the dramatically reduced density of MAPLE-deposited PMMA, was corroborated by X-ray reflectivity measurements that estimated an ~ 38 % reduction of density.

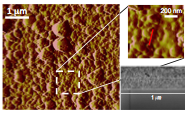

We believe the concurrent enhancement in thermal/kinetic stability and reduction in density is due to the film morphology. Figure 2 shows the surface topology of a MAPLE glass with Tsubstrate = 336 K, as revealed by AFM. Noticeably, the surface structure of the MAPLE-deposited film contains spherical-like globules. The globules range in size from ~ 20 – 500 nm and would each contain a few to tens to thousands of polymer chains. The surface structure of the film suggests that glass formation proceeded by the assembly of polymer globules to form a supramolecular nanostructured glass. The cross-sectional SEM image of Figure 4 supports this claim, as sub-surface nanoglobules are clearly visible.

Figure 2: AFM amplitude image of MAPLE-deposited PMMA film with Tsubstrate = 336 K and cross-sectional SEM image of the film.

Career and educational impact. Funding of this proposal has allowed our group to initially explore the impact of nanoscale confinement and interfaces on Tg and physical aging of confined polymer, and to investigate the stability of glassy polymeric films deposited by MAPLE. Our work is the first to show that MAPLE-deposited glassy polymeric films exhibit a significant enhancement in thermal and kinetic stability. A postdoctoral fellow and a graduate student have carried out this work. Funding of this proposal has allowed them to develop a fundamental understanding of confinement effects on the properties of polymers and develop the ability to process films by MAPLE.