www.acsprf.org

Reports: DNI748927-DNI7: Structural Relaxation of Polymers in Nanoconfined Geometries: Reconciling the Accelerated and Suppressed Physical Aging Observed in Different Systems

Connie B. Roth, PhD , Emory University

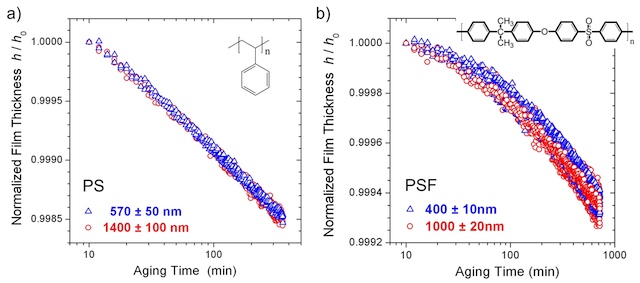

Our recently developed streamlined ellipsometry procedure [2] is able to characterize the physical aging rates of polymer films with varying chemical structure. We compare the physical aging rate as a function of film thickness of two canonical polymers supported on silicon using this common experimental technique. Figure 1 plots the normalized film thickness, h/h0, as a function of the logarithm of the aging time for films supported on silicon as measured by ellipsometry. Polystyrene (PS) (Fig. 1a) is a common C-C backbone polymer with a large bulky aromatic side-group that limits packing (Tg = 100 oC, fractional free volume FFV = 0.176). Polysulfone (PSF) (Fig. 1b) is a common polymer used in gas separation membranes, whose packing is limited by the stiff aromatic groups along its backbone (Tg = 186 oC, FFV = 0.156). For each polymer, the same aging rate is observed independent of film thickness: for 570 and 1400 nm thick PS films aged at 65 oC for 6 h, and for 400 and 1000 nm thick PSF films aged at 100 oC for 12 h. The aging temperatures were chosen to be close to the peak in aging rate for the two polymers.

Figure 1: Varying chemical structure.

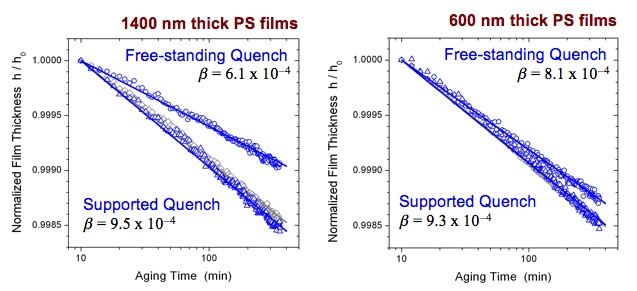

We have found that faster physical aging rates with decreasing film thickness at large micron length scales can been observed in a flexible C-C backbone polymer, with a lower Tg than the polymers typical of separation membranes, when these films are quenched in a freestanding state matching the sample preparation procedure used in the gas permeation work. Figure 2 compares the physical aging behavior of PS films that have been thermally quenched under different conditions at the start of the aging measurement. The graphs plot the normalized film thickness, h/h0, as a function of the logarithm of the aging time for films aged at 65 oC for 6 h. The upper lines (circles) correspond to 1400 nm or 600 nm thick PS films quenched in a freestanding state held by a square wire frame and then gently transferred to a silicon wafer for the aging measurement. The lower lines (triangles) correspond to the same film subsequently reheated above Tg and quenched in a supported state on the silicon. The gray data underneath correspond to PS films of equivalent thickness spin coated directly onto silicon and quenched in a supported state. Clearly, the difference in physical aging rates between films quenched in a freestanding vs. supported state is much less for the thinner (600 nm thick) films. The data shown in Fig. 2 demonstrate that accelerated aging, i.e., faster physical aging rates for thinner films, is observed when PS films are quenched in a freestanding state, consistent with the measurements from the gas permeation community. However, no film thickness dependence to the aging rate is observed when the films are quenched in a supported state. Thus, the factor that affects the aging characteristics of the film is the state of the film during the thermal quench and formation of the glassy state. The state of the film in the glassy state during the aging measurement, freestanding vs. supported, does not affect the physical aging rate.

Figure 2: Varying film support during thermal quench.

In order to identify the cause of this behavior, we have investigated the effects of annealing time and temperature above Tg, cooling rate, quench temperature, and various film geometries during the thermal quench.[3] Based on process of elimination, we believe the film thickness dependence of the aging rates observed at micron length scales in the gas permeation studies is due to small differences in stress inadvertently applied to the freestanding films by the film support during the thermal quench. Since all thin films must be supported in some manner, understanding the unintended stresses resulting from thermal expansion mismatches between film and support are important. These studies indicate that even small stresses, only present during the formation of the glassy state, can strongly influence the subsequent stability of these films even when this stress is removed during the aging process. An improved understanding of how quench conditions affect glass formation could be used to control glassy film properties leading to materials with improved stability.

[1] Roth, C. B. J. Polym. Sci., Part B: Polym. Phys. 2010, 48, 2558-2560. "Mobility and Stability of Glasses"

[2] Baker, E. A.; Rittigstein, P.; Torkelson, J. M.; Roth, C. B. J. Polym. Sci., Part B: Polym. Phys. 2009, 47, 2509-2519. "Streamlined Ellipsometry Procedure for Characterizing Physical Aging Rates of Thin Polymer Films"

[3] Gray, L. A. G.; Yoon, S. W.; Pahner, W. A.; Davidheiser, J. E.; Roth, C. B., "Effect of Quench Conditions on the Subsequent Physical Aging Rate of Polymer Glasses," in prepration.