www.acsprf.org

Reports: UNI649527-UNI6: Fundamental Studies of Atmospheric Pressure Microhollow Cathode Discharge Plasma Jet Interaction with Liquid Media

WeiDong Zhu, PhD , Saint Peter's College

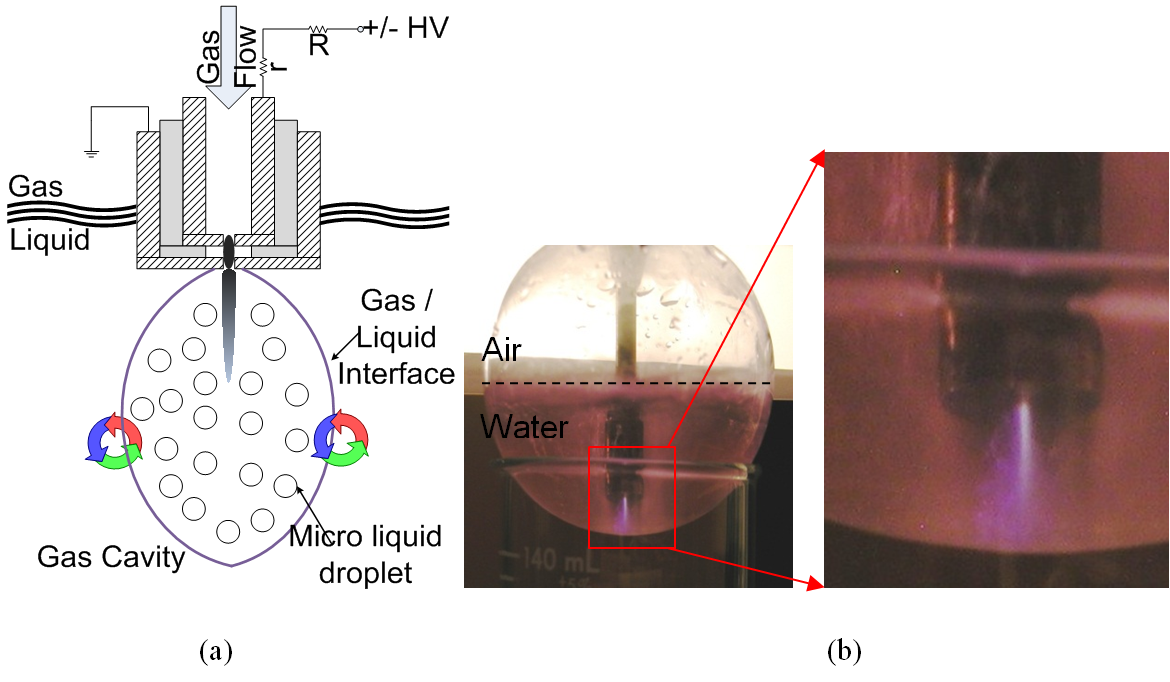

The PMJ device comprises two

metal tubes separated from each other by a third insulating tube. The key

dimensions are the inter-electrode distance and the diameter of the exit

nozzle, which are 0.5 mm and 0.8 mm, respectively. Compressed air, helium/ oxygen

mixture were used as the working gas. Gas flow rate usually ranges from 0.3 to

5 standard liters per minute. The discharge sustaining voltage varies in the

range of 230 ¨C 600 V (depending on the working gas used and its flow rate) with

an operating current in the 3 ¨C 40 mA range. A schematic diagram of the PMJ

device as well as a picture of the plasma sustained in liquid can be found in

the previous annual report. This

report focuses on the interaction of PMJ with liquid media when PMJ is

sustained in a quasi-steady gas cavity in liquid. Figure 1. (a) A schematic diagram of the PMJ generated in a

quasi-steady gas cavity in liquid

and (b) pictures of the PMJ (with compressed air as the feed gas) working

in deionized water with Rhodamine WT . When the tip of the device is

immersed in liquid media, the continuous gas flow through the orifice maintains

a quasi-steady gas cavity, which protects the powered electrode and

subsequently keeps the gas discharge plasma sustained (as demonstrated in

figure 1). The plasma activated species (such as ions, excited species, and

electrons) is directly injected into the liquid via the opening. Chemical

reaction of plasma activated species with liquid solution happens effectively

at the surface of the gas cavity and more importantly, on the surfaces of

micro-liquid droplets that exist within the gas cavity (as denoted by the

little circles within the gas cavity in figure 1 (a)). In one series of experiments,

200 ppb Rhodamine WT was used to purposely

contaminate 200 ml de-ionized water and subsequently treated with PMJ for one

hour. The concentration of Rhodamine WT was degraded

to ~ 80 ppb. Exemplary pictures of the initial liquid and the treated liquid are

shown in figure 2, qualitatively demonstrating the change of the concentration fo Rhodamine

WT. Figure 2. A picture of deionized water with Rhodamine WT contamination before and after 1 hour PMJ

treatment (totally treatment volume is 200 ml and with compressed air as

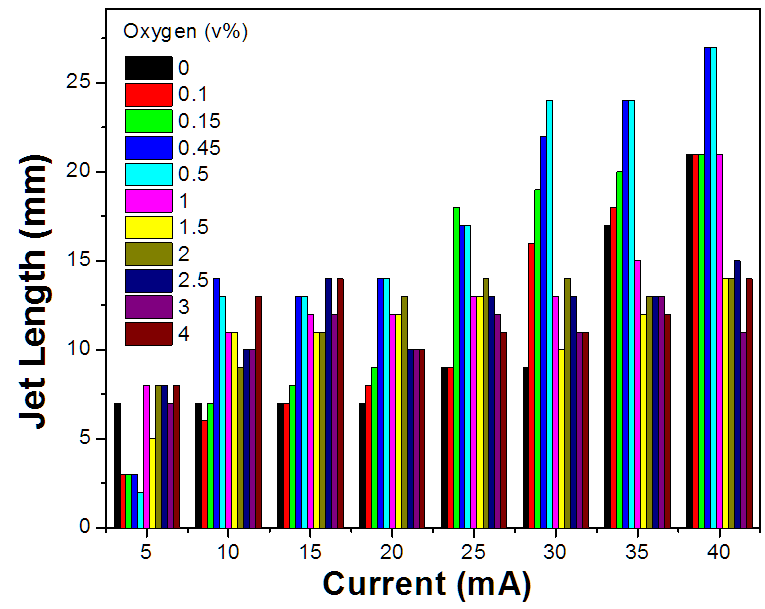

working gas). Figure 3. Jet length as a function of discharge current at

different oxygen volume concentration (flow rate: 2 standard liters per minute) No matter what gas is used as

the working gas and at what flow rate or discharge current, it is important

that a stable PMJ has to be generated in air before the interaction with liquid.

In the case of helium/oxygen mixture as working gas, a general trend observed

is that with the increase of oxygen concentration, the overall voltage needed

to sustain the plasma is increased. The visible length of the jet in general

increases with the increase of the discharge current (at oxygen concentration

below 1%). This phenomenon is not as obvious when oxygen concentration is

increased to above 1%. At a fixed oxygen concentration (<2%), the jet length

also increases with the flow rate until it reaches a plateau when entering the

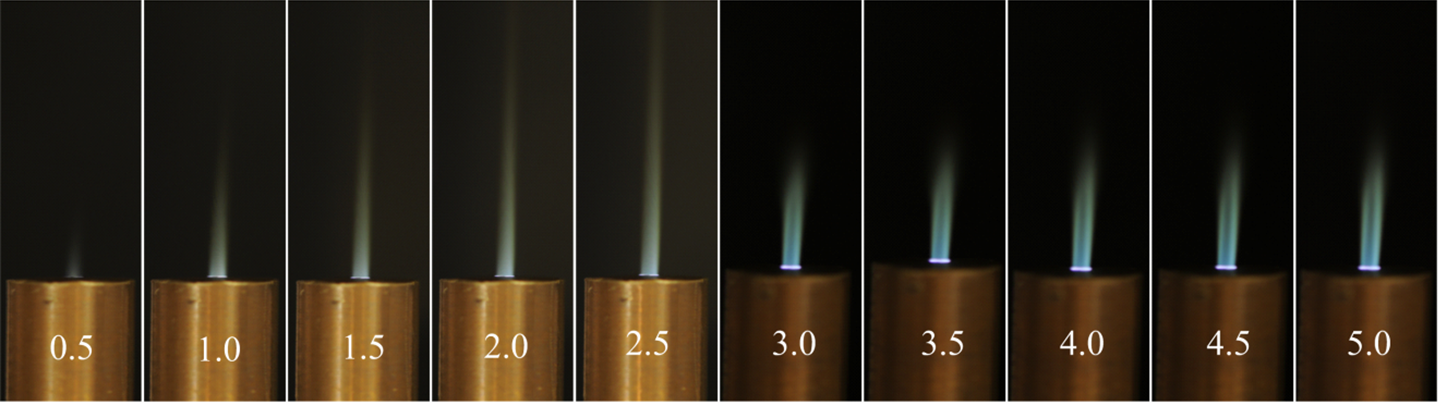

turbulent mode (as shown in figure 4). Figure 4. Pictures

of a He/O2 (2%) plasma microjet (a) at

flow rates from 0.5 to 5 slm (diameter of the end cap

opening: 800 mm), Discharge current: 30 mA The transition from laminar

flow to turbulent flow happens between a flow rate of 2.5 slm

and 3.0 slm which correspond to Reynolds number

between 603 and 724. Atomic oxygen is considered

as one of the key components in the plasma generated species as they can

directly participate in the oxidation process of organic and inorganic species in

air and in liquid, as well as serving as the precursor of other reactive oxygen

species (ROS). Atomic oxygen (with optical emission at 777.4 nm) was monitored

via visible optical emission spectroscopy (OES) when different volume percent

of oxygen was added into helium carrying gas. It is interesting to note that

relative oxygen emission intensity reaches a peak value at around 0.1% oxygen

concentration (as shown in figure 5 (a)). This oxygen emission can originate

from the O2 added to the helium stream as well as the air

entrainment. Emission monitored from side-on of the jet at a distance 3 mm away

from the exit nozzle revealed similar trend. Figure 5. Relative optical emission of oxygen at 777.4 nm at

(a) different oxygen volume percent from end-on and side-on at 3 mm and (b)

different flow rate

When fixed

at a certain oxygen concentration (0.1%), the optical emission of oxygen peaks

at a flow rate of 4 slm. It is very likely that at a

higher flow rate, mixing of surrounding air exceeds the optimal oxygen volume

concentration that can lead to the maximum oxygen emission.

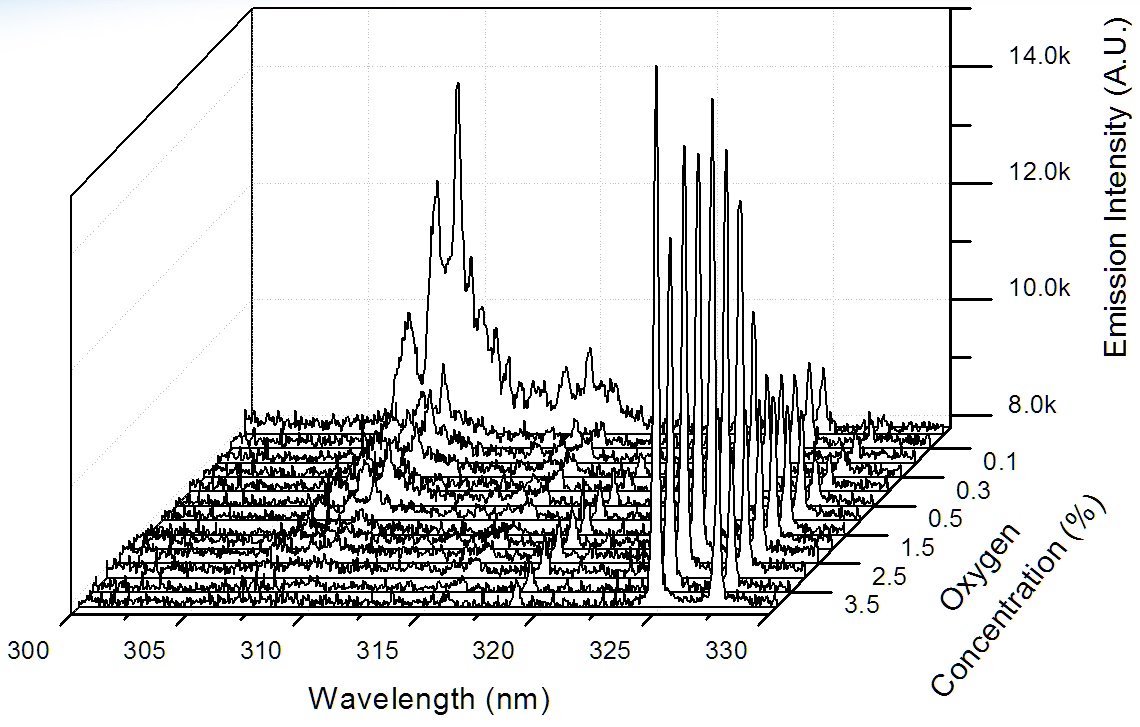

Figur 6. Optical Emission of OH (306-309 nm) and Cu (325 nm and

327 nm) at different oxygen concentrations Meanwhile, optical emission

of OH and Cu at different oxygen concentrations are also monitored and shown in

figure 6. OH emission peaks when no oxygen is added into the working gas, while

Cu emission increases with the increase of oxygen concentration. It is rather

difficult to monitor light emission when the PMJ is sustained inside water. Therefore

no emission spectra are recorded in those cases. This project has given me a

chance to work with students from high school level all the way up to senior

college students. In an undergraduate college, this experience is invaluable. I

am glad to see many of them graduate from high school and move on to

college/university, pursuing a science career because their experience in my

lab.