www.acsprf.org

Reports: DNI949744-DNI9: Effect of Polymer and Polymer Gel on Disproportionate Permeability Reduction to Gas and Water for Tight Gas

Baojun Bai, PhD , Missouri University of Science and Technology

Background

Excess water production is one of the most prevalent operational problems facing gas companies. Polymers and polymer gels have been widely used to control excess water production in conventional hydrocarbon production assets. Water/oil or water/gas flows in porous media are strongly modified in the presence of polymers or polymer gels on the pore. So the polymers or polymer gels are often called relative permeability modifier (RPM). However, previous experiments on RPM were mostly focused on conventional rocks without fractures. The conduits for fluid flow in tight and shale gas reservoirs are primarily the natural fractures. However, there is no published literature to report to what extent that polymer can reduce water permeability more than to gas permeability in fractured flow path.

Objectives

The overall objective of this project is to advance the fundamental science and the in-depth understanding of disproportionate permeability reduction mechanisms of polymer to gas and water in tight gas. Using this knowledge, we can design new relative permeability reduction agents that will lead to maximize the disproportionate permeability reduction of relative permeability modifier (RPM) to gas and water in gas shales during gas production. Applications from these study results would provide information towards the implementation of the novel concepts on RPM as well as improve results of mitigating excess water production from tight gas and shale gas reservoirs.

Results

1. Wettability/Contact Angle Measurements

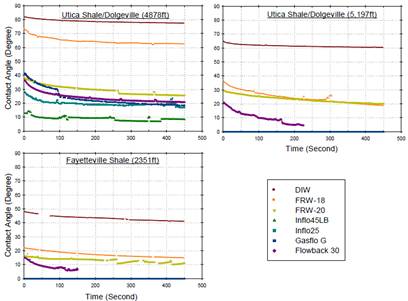

Rock wettability is very important because the interaction between rock surface and fluid composition can greatly affect the gas flow in submicron pores. To fully understand this problem, intensive study of shale rock surface and fluid composition interaction needs to be performed. Rock wettability is basically defined by the contact angle measure. Figure 1 shows the obtained contact angle measurements from Utica and Fayetteville shale samples using two polymers and four surfactants. Tested fluids on Utica and Fayetteville shale rock samples result in reducing the contact angle and making the shale rocks behave more water-wet like surface compared to DIW contact angles.

Figure 1. Contact Angle Results for Utica and Fayetteville Shales Using Various Fluids

2. Mercury Injection Porosimetry

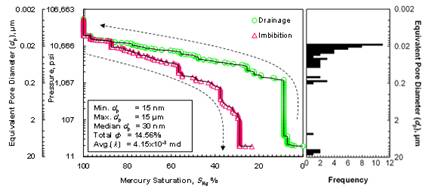

Mercury porosimetry analysis of shale gas rocks is essential and can determine the distribution of pore-throat sizes and understand the structures of pore systems in the reservoir. The petrophysical properties of shale gas rocks are significantly different from those of conventional oil and gas reservoirs because of the nano-scale pores and unique pore structure of shale gas rocks. Therefore, high mercury intrusion pressure (up to 60,000 psi) instrument is used to measure shale gas pores at nano-scale. Figure 2 presents mercury intrusion and extrusion curves of Utica shale alongside the resulting pore size histogram. The crooked curve of the intrusion and extrusion process is an indicator of various pore sizes. The resulting Utica shale median pore throat diameter is 30 nm and most of the intruded mercury corresponds to a pore throat size of 20-200 nm.

Figure 2. Mercury Injection Porosimetry Test Results of Utica Shale

3. Submicron-Scale Pore Imaging

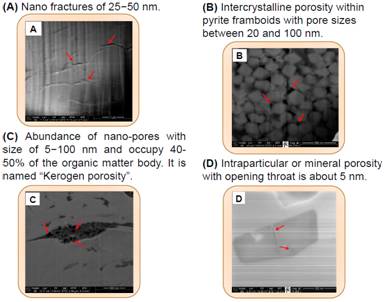

Scanning Electron Microscope (SEM) has been widely used in material science studies. It is especially useful for structure and material characterization. It is currently considered the best method for imaging the microstructure of gas shale samples. SEM images in Figure 3 demonstrate many porous bodies that could be favorable candidates for gas storage. Various types of porosities (e.g., interparticular, intergranular, kerogen, vuggy, pyrite framboids, and fractures) were observed. Pores of organic matter were found in nano-sizes occupying 40-50% of the kerogen body.

Figure 3. Various Porosity Types in Shale Gas Rocks

Future Work

1. Test the extent to which typical relative permeability modifiers (RPM) reduce water permeability more than gas permeability for tight gas and shale rocks with fractures using the coreflooding apparatus.

2. Study the mechanisms of disproportionate permeability reduction by using the single-molecule imaging system.