www.acsprf.org

Reports: DNI550429-DNI5: Fundamental Insight into the Hierarchical Engineering of Nanoparticulate and Templated Porous Films for Molecular Separations

Mark A. Snyder, PhD , Lehigh University

The ability to synthesize ultra-thin porous inorganic films with tunable, highly ordered pore topologies holds implications for molecular selectivity and flux as it relates to membrane-based gas, vapor, and liquid separations. Identification of a versatile strategy for shrinking porous inorganic film thickness by orders of magnitude has proven elusive, but represents a potential breakthrough technology for realizing industrially relevant permeances and impacting separations based energy savings. The overarching goal of this work, therefore, is to establish a facile strategy for simultaneously tuning pore size and film thickness of porous inorganic films, the latter to the level of just tens to hundreds of nanometers.

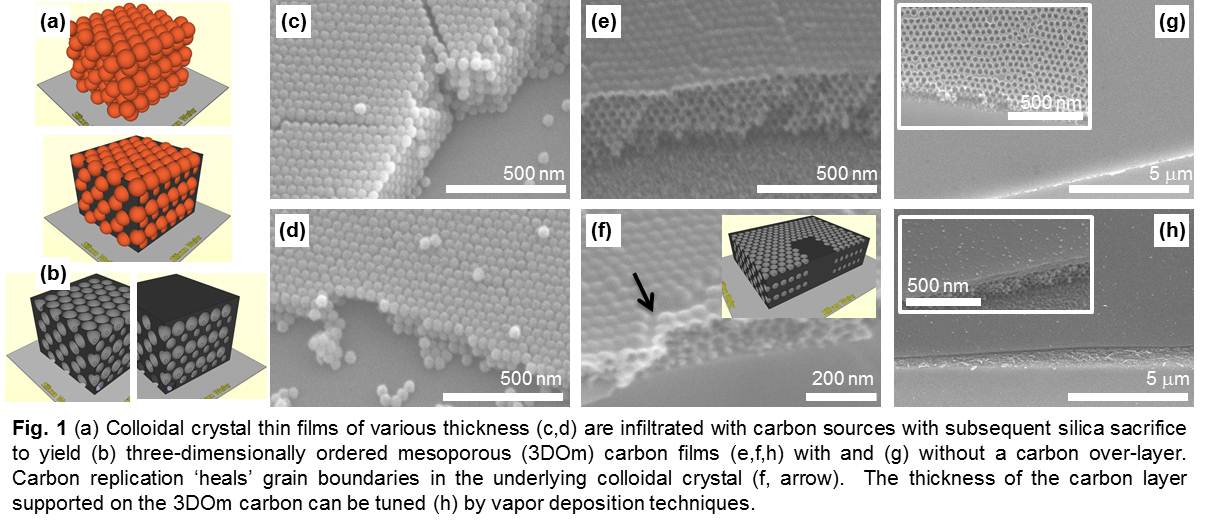

Progress to date has focused on 1) the synthesis and characterization of ultra-thin mesoporous and mesopore-supported microporous carbon films, and has led to 2) the development of proof-of-concept strategies for scaffolded growth of thin crystalline membranes (i.e., zeolites) as described below. These developments have been accomplished via a hierarchical strategy (Fig. 1ab) rooted in the ability to tune the size of silica nanoparticles from 5 to tens of nanometers and convectively assemble them into highly ordered monolayer to multi-layer nanoparticulate colloidal crystal thin-film (sacrificial) templates. Control over the primary particle size and colloidal crystal film thickness offers a facile and direct means for tuning the pore size as well as thickness of the mesopore and micropore layers of replica films.

3DOm and 3DOm-supported microporous carbon films

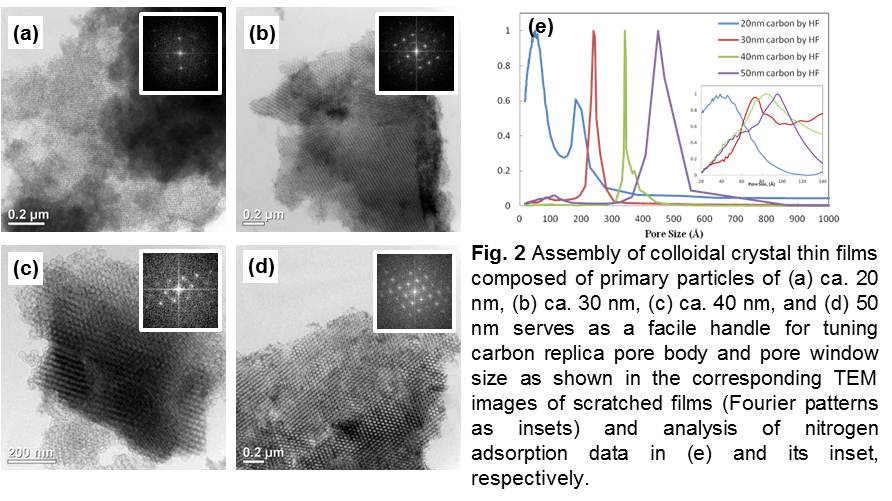

Convective deposition was exploited as a means for scalable assembly of size-controlled (10-50 nm) silica nanoparticles from aqueous solution onto solid non-porous substrates (e.g., silicon wafer) whereby film thickness can be tuned by coating conditions (Fig. 1cd). While locally ordered, grain boundaries formed due to capillary forces during film deposition and drying are expected to have a parasitic effect on separation attempts based upon the porous nanoparticulate films. Alternatively, we have explored how these nanoparticulate films can be employed as pre-formed and tunable templates for the realization of films of other compositions. Specifically, we have studied carbon replication of these colloidal crystal thin films through infiltration of furfuryl alcohol and oxalic acid followed by confined polymerization, carbonization, and selective silica removal via either buffered hydrofluoric acid or alkaline etching with KOH. Robust and defect-free carbon films (Fig. 1e-h) result in which grain boundaries within the template silica film are healed' through filling by the carbon source (e.g., arrow, Fig. 1f). By tuning the conditions employed for infiltration of the carbon source among capillary introduction and vapor-based filling or a combination thereof, and exploiting the hydrophilicity of the silica colloidal crystal film, final film morphology can be tuned from purely 3DOm carbon films (Fig. 1g) to 3DOm supported-defect-free carbon layers (i.e., microporous due to KOH activation) (Fig. 1efh), the thickness of which can be tuned with nanometer resolution by vapor-based processing (Fig. 1h). The ability to control the mesopore film thickness and 3DOm body size by tuning thickness and primary particle size of the colloidal crystal template, respectively, underscores the versatility of this approach for tuning critical film properties (Fig. 2).

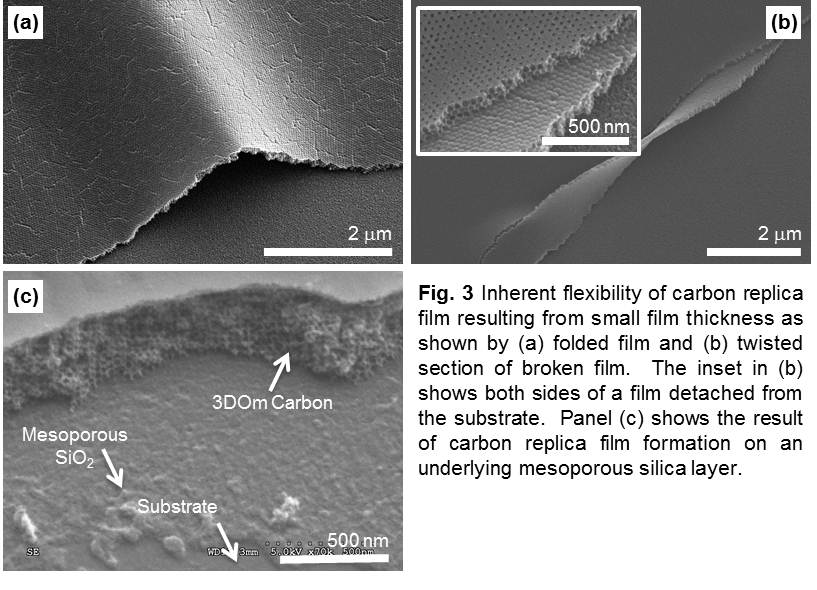

Moreover, the thin film dimensions lead to inherent film flexibility as evidenced in Fig. 3ab for a case where the porous carbon film has been detached from the underlying substrate. Exposure of the substrate side of the detached film clearly shows that complete carbon infiltration of the colloidal crystal template has been achieved, with equivalent pore accessibility from the top and bottom of the film. The ability to detach the film from the substrate should facilitate film transfer to rough, highly porous substrates critical for membrane based applications. Alternatively, we have carried out proof-of-concept studies that show that equivalent, ultra-thin carbon films can be realized on sol-gel derived mesoporous silica layers, a common intermediate employed for smoothing the inherent roughness of highly porous membrane supports (Fig. 3c).

Scaffolded growth of ultra-thin zeolite films

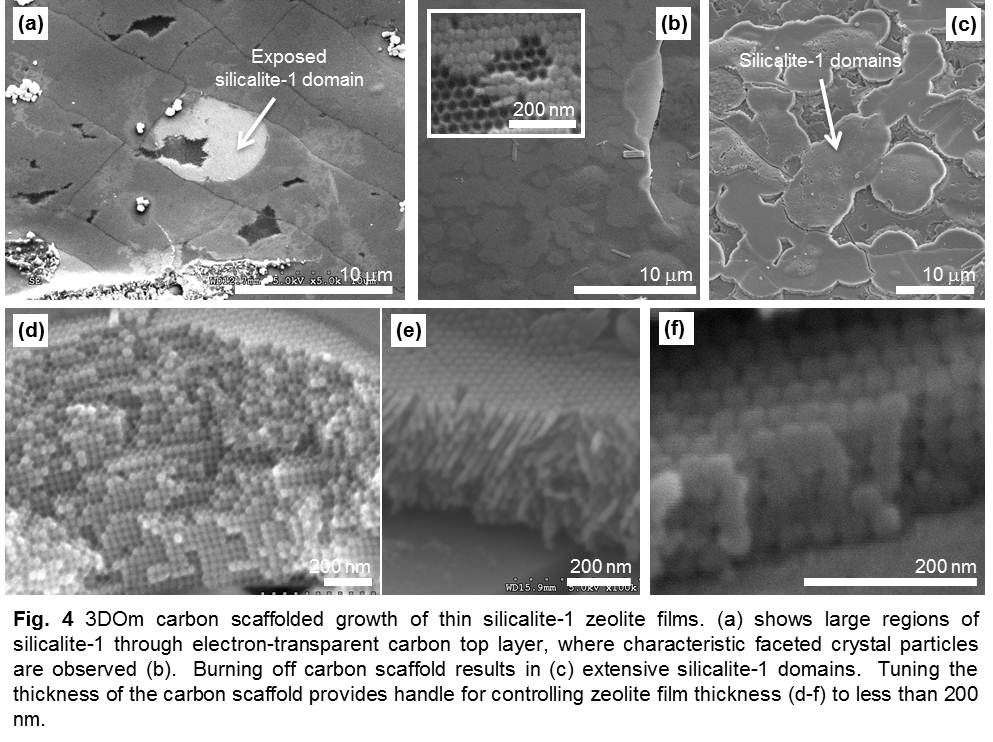

While the ability to control thickness and pore size/ordering in mesoporous films and mesopore-supported microporous films holds implications in achievable permeances in large- to small-molecule separations, we have explored how the resulting 3DOm-supported carbon thin films (or their pre-carbonization polymeric precursors) can be exploited for confining the growth of ultra-thin zeolite membranes. Confined crystallization and growth of zeolites (e.g., silicalite-1) within the carbon replica films has been demonstrated (Fig. 4), with this hierarchical approach holding promise for realizing zeolite films and membranes that are orders of magnitude thinner than what is typically achieved by secondary growth techniques common to the zeolite membrane community. Preliminary evidence suggests that control over synthesis conditions (e.g., temperature, solution concentration) enables the growth of extensive, high-aspect ratio single crystal domains of thin (100 nm) zeolite films (Fig. 4).

Future Work

Ongoing and future work aims to leverage this thin film templating/scaffolding strategy for synthesizing thin films on, or successfully transferring them to, porous supports for assessment for molecular separation capabilities. In addition, ongoing efforts are focused on elucidating how the size, functionality, and charge of the primary silica particles can be tailored in order to affect the assembly of ordered thin film templates of tunable particle coordination, and thereby identify a means for tuning pore topology in the replica pores.

Impact

We believe that this templating strategy employing cheap and easily assembled silica nanoparticles represents a versatile approach to realizing films of a wide range of compositions. Future work will aim to exploit template chemistries to understand the role of the template in realizing other inorganic and crystalline thin films. Support through this ACS PRF grant has provided the resources to jump start a new project for the PI, and has proven critical for generating new insights and preliminary data as the basis for proposals having an expanded scope. The grant to date has supported one doctoral researcher and has provided the infrastructure for carrying out related research.