ACS PRF | ACS

All e-Annual Reports

44112-G10

Effects of Admolecule Velocity on Kinetics of Organic Semiconductor Crystal Growth

Organic vapor jet printing (OVJP) is a technique developed by Shtein, and involves sublimating molecules into a hot inert carrier gas, which is then ejected through a microscopic nozzle (or an array of nozzles) forming a highly collimated gas jet. The jet impinges on a cooled substrate, with organic molecules selectively adsorbing onto the substrate, forming a deposit whose size and shape are controlled by nozzle geometry, distance to substrate, pressures, and type of carrier gas used. Using a gas instead of a liquid solvent allows printing of multilayer structures that improve optoelectronic device performance.Â

This project was aimed at investigating growth mechanisms and crystallization in the deposited films resulting from the non-equilibrium nature of the process.Â

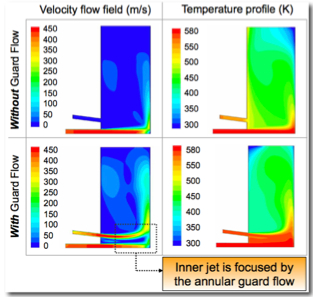

To mitigate vendor's delays in delivery of experimental components, we began the project by modeling the flow dynamics of gas and vapor jets to understand the velocity and pressure distribution, and their effect on thin-film deposition. We obtained predictions for a range of process parameters; an example is shown in Fig. 1 (top row), where the velocity flow field and temperature profile are obtained for a typical set of process conditions. Using these simulations, we also developed a modified jet printing approach, that used an annular guard flow of inert carrier gas to surround the main vapor jet, enhancing the collimation of the vapor jet, and shielding it from the surrounding atmosphere, as illustrated in Fig. 1 (bottom row).

Figure 1: An example of the output produced by the computer simulations of OVJP and G-OVJP. The top row shows the velocity and temperature distribution for a typical set of OVJP conditions, while the bottom row shows the same for Guardflow-enhanced OVJP.Â

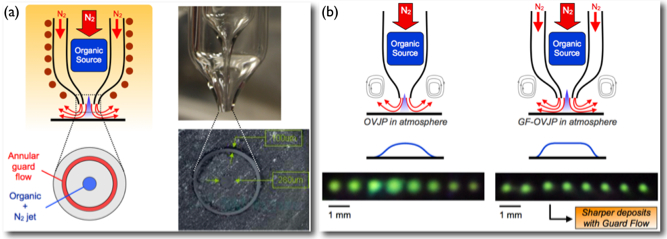

A vapor jet printing apparatus incorporating the guard-flow modification was fabricated, and is shown in Fig. 2a. This instrument was used to print patterns of AlQ3 - a common electron transporting organic semiconductor. As shown in Fig. 2b, the guardflow enhances collimation and results in narrower deposits.Â

Figure 2: (a) A diagram of the G-OVJP nozzle, along with a micrograph showing the nozzle. (b) A cartoon illustration of the different flow patterns in OVJP and G-OVJP, accompanied by fluorescence micrographs of AlQ3 deposits, indicating the collimating effects of the guardflow.Â

Figure 2: (a) A diagram of the G-OVJP nozzle, along with a micrograph showing the nozzle. (b) A cartoon illustration of the different flow patterns in OVJP and G-OVJP, accompanied by fluorescence micrographs of AlQ3 deposits, indicating the collimating effects of the guardflow.Â

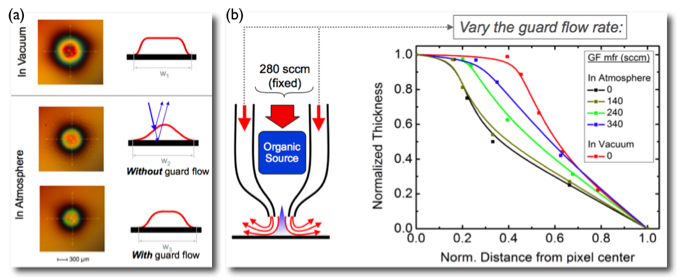

To confirm collimation due to guardflow, we studied the shape of the deposits by interference microscopy (Fig. 3a). We found that the pixel shape is indeed strongly influenced by the presence of the guardflow (Fig. 3b).Â

Figure 3: (a) Illustrations of the deposit shapes obtained by the various modes of OVJP and of an interference-based method to determine pixel shape. (b) A plot of the pixel thickness versus radial distance in the pixel for different deposition conditions in G-OVJP.Â

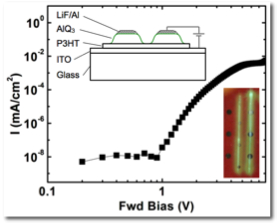

Our findings confirmed the hypothesis, and are important for several reasons. Firstly, achieving good pattern resolution in atmosphere can lower device (e.g. OLED-based display) fabrication costs. Secondly, the flow simulations and the observed pixel narrowing imply an ability to shield the hot organic vapor by the guardflow from degradation by various species (e.g. O2, H2O). Our preliminary experiments in depositing OLEDs by G-OVJP yielded OLEDs that exhibit very typical current-voltage (I-V) behavior, shown in Fig. 4.

Figure 4: (Inset 1) A cross-sectional schematic of the test device, with a top-view photo shown in the lower inset. (Plot) Current-voltage characteristic of the OLED in forward bias.Â

Having shown these results at a conference, we received considerable interest from a large display manufacturer in a collaborative effort to develop the G-OVJP technique further and to validate it for more commercially relevant materials and device structures.Â

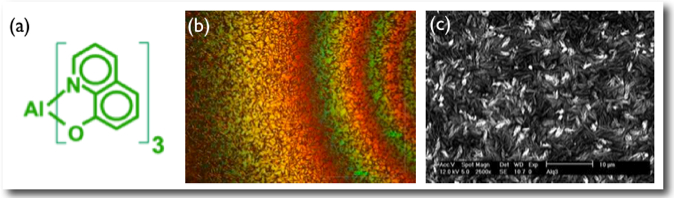

The films deposited by G-OVJP and described above were amorphous. We also were able to force crystallization of AlQ3 during deposition, as shown in Fig. 5. We are currently performing crystallography on these deposits, and are investigating the possibility of forming morphologically varied thin-film sequences (i.e. amorphous / crystalline / amorphous / crystalline) using the G-OVJP technique. We anticipate this work to yield scientifically and technologically important results. For example, we can form chemically homogeneous but morphologically different interfaces to examine the role of molecular order in charge, exciton, and phonon transport in organic materials. Another possible direction is to deposit crystalline hole and electron transporting layers, sandwiching amorphous emissive layers to improve charge injection and transport in OLEDs.Â

Figure 5: (a) Molecular structure of AlQ3. (b) A micrograph of an AlQ3 deposit formed in atmosphere by G-OVJP. (c) A SEM image showing under magnification a region of the deposit in (b). Micrometer-scale crystallites of AlQ3 can be clearly seen.Â

Figure 5: (a) Molecular structure of AlQ3. (b) A micrograph of an AlQ3 deposit formed in atmosphere by G-OVJP. (c) A SEM image showing under magnification a region of the deposit in (b). Micrometer-scale crystallites of AlQ3 can be clearly seen.Â