ACS PRF | ACS

All e-Annual Reports

40602-B10

Comminution Dilatancy in Nanoparticle (Organic Nanopigment) Formation

Year 2 focused on pigment comminution and on investigating whether or not the claims in the seminal Kodak Patent were reasonably founded. We focused on using two methods of comminution: (1) high speed disc stirring; (2) low speed roller mill comminution. Sunfast Blue, Sunfast Magenta, and Clarient Yellow were the three commercially available pigments used.

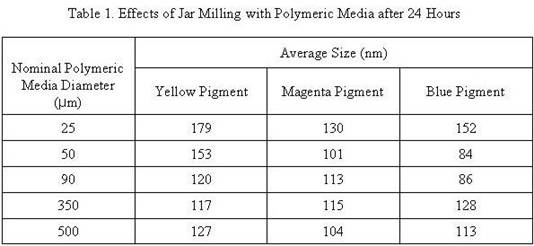

Results for jar milling using of 25-500 μm diameter are illustrated in Table 1 for the three pigments. The results for initial slurries all greater than 200 nm in average diameter do not present a convincing picture that small micro media are superior.

Using high speed stirring with a minidisk stirrer (a Brookfiled viscosity probe with the nub below the disk ground off. The disk diameter was about 1 cm. Grinding was done at about 4000 rpm. Results in Table 2 for two runs of high speed stirring using the Clarient Yellow pigment show that the mean particle size decreases until the media are in the range of 25-50 μm. These data generally support the Kodak claims to producing nano-sized pigments. Comparison with the jar milling results in the last column suggest the mean size heavily depends on the method of grinding as well as on the properties of the grinding media. Here it appears the best milling results are obtained with the three largest sized beads, rather than with the smallest beads. High speed stirring with ceramic media in the 100-800 μm range were less effective in reducing particle sizes below the initial 265 nm mean starting size, and are not listed in Table 2.

The shear field produced by the 1.4 cm diameter disk stirrer at 4000 rpm, 1 cm above the bottom of the reactor (vial) is about 290 s-1 at the outer edge of the disk, but it falls off quickly to zero at the center of the disk. The stirring disclosed by Kodak utilizes a 20-cm diameter disk rotating at about 1000 rpm about 10-15 cm above the bottom of the reactor. This stirring produces a maximum shear field of about 70 s-1 at the outer periphery of the disk.

These experiments suggest that moderate shear fields in disk stirring geometry can produce sub-100 nm diameter dispersions of organic pigments. An important part of the size reduction mechanism is that low shear mixing of media produces spikes and sudden jumps and fall-offs in the effective stress, even under low macroscopic shear fields. The media size effects are clearly depend on the actual mixing method and geometry. The disk stirring effects support the Kodak claims, showing that 50 μm polymeric media effect significant size reductions, surpassing those of much more dense ceramic media.

We then focused on the jamming phenomena discovered in year 1, where we studied the stress produced by simple rod or bob spinning in a bed of dry comminution media. Work in this third year continued without expending funds due to the student, Nolan McGraw, pursuing this work as 6 credits of independent study in the 2008 winter semester. In these studies we focused on the effects of mixing two differently sized polymeric media, where 25 μm media were “doped” into a bed of 90 μm. This series of experiments seeks to discover “designed jamming” for more controlled and predictable and faster size reduction development of nanopigment dispersions using micromedia.

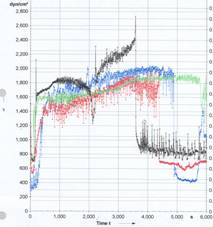

The basic experiment examined the effects of adding 25 μm media to 90 μm media over the range of 0-15%. Typical runs were carried out for 6000 seconds. Such experiments were done for various compositions, expressed as wt percent of small beads, 25 μm, mixed with 90 μm diameter beads. The basic chaotic behavior reported in year 1 is reproduced below as a reference:

This behavior was reproduced (at 150 rpm) and as the wt% of added small beads was increased, a very high frequency noise spectrum appeared superimposed upon the basic “background” chaotic curves. As the amount of added small beads is increase from 1 to2 to 7 wt%, the superimposed high frequency noise becomes more uniformly distributed over the underlying “chaotic” curves, indicating a higher frequency of jamming events.

In the above figure at 7% wt% small beads, we see background chaotic motion of the 90 μm media. We also see a very high frequency “noise” superimposed. As the small bead wt% is raised to 10 and then to 15%, the magnitude of the “superimposed noise” decreases, and the frequency of this noise appears to decrease.

Mixing small media that will fit into tetrahedral holes of larger media appears to produce a high frequency jamming effect superimposed upon the basic chaotic motion exhibited by the larger beads. Both of these effects are expected to lead to increased nanofracturing of substrate pigments.