ACS PRF | ACS

All e-Annual Reports

45359-AC10

Sonoelectrochemical Approach towards Novel Nanostructured Thermoelectric Materials

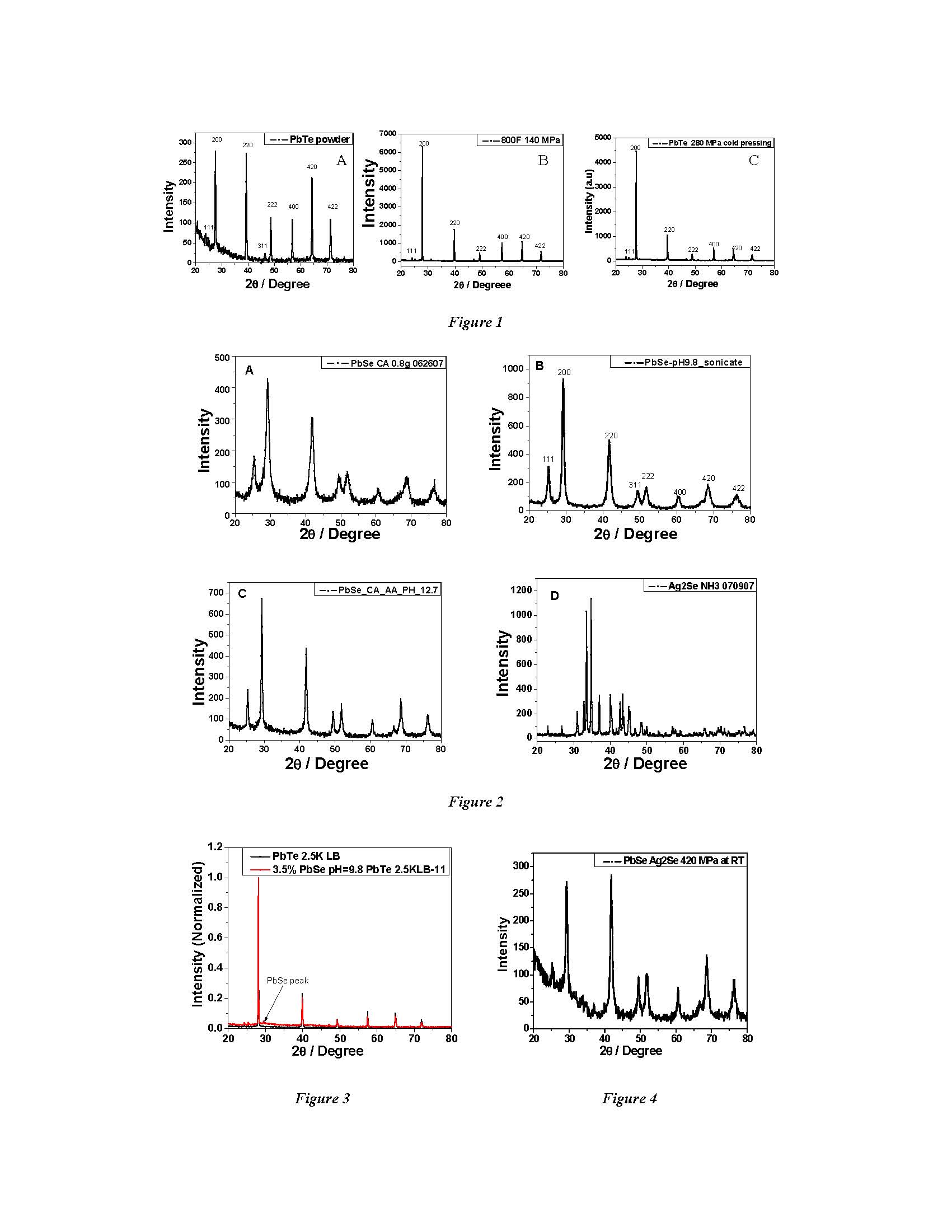

ACS-PRF Report 2007 – Clemens Burda, Case Western Reserve University The project on the sonoelectrochemical synthesis of novel thermoelectrics (TE) is progressing efficiently towards the development of novel and more efficient TE materials. We have spent the past months on elaborating the most efficient synthesis conditions and currently converge on a method that produces nanostructured materials with macroscopic dimensions. This allows to produce better TE's based on the nanoscale-enhanced thermoelectric transport conditions, and simultaneously having a macroscopic material at hand. We have focused on producing pressed pellets, which are hybrid materials of micron-sized TEs, such as PbTe. This pellets are loaded with nanostructures which are responsible for the decreased phonon transport. Hot and cold pressing conditions The pressing conditions were optimized by pressing a PbTe micron-sized powder under different pressures and temperatures. The pressure for the cold pressings has been varied from 140 MPa to 420 MPa for one hour at room temperature. The experiments show that the higher the pressure, the more is the density of the pellet close to the bulk values of PbTe. However, a temporary challenge was that the pellets easily stick on the cast for the pressing under higher pressures. The suitable pressure range for the cold pressing turned out to be from 280 MPa to 420 MPa. The best pressures for hot pressings are from 210 MPa to 280 MPa, and a temperature range from 800 F to 932 F. The hot pressed TE's have further mechanical and chemical challenges that we are working on. They are quite brittle and can oxidize because at the high temperatures, therefore we are also working on environmental atmospheric control during the pressings. In figure 1, shown are the XRD results of the PbTe powder, as well as hot and cold pressed PbTe pellets. Figure 1. Pressings of the TE matrix materials at different pressures and temperature for optimization of the processing conditions. A) PbTe powder unpressed B) PbTe pressed at high temperature and lower pressures C) PbTe pressing at high pressure and room temperature. Sonochemical Synthesis of PbSe and Ag2Se Nanoparticles The nano-structure component of the TE materials is being developed with a sonoelectrochemical synthesis approach. The PbSe NPs are being synthesized through reacting Pb2+ with Na2SeSO3 under sonochemical synthetic conditions to achieve differently sized NPs as the doping NP component for the PbTe matrix material. The broad XRD peaks show that they are all nanometer sized particles. The Ag2Se nanoparticles were synthesized through reacting Ag+ with Na2SeSO3 under sonochemical conditions to achieve different sized NPs as the doping NPs in PbSe NPs as the matrix. Doping concentrations that we are currently exploring vary from 1-20%. Below are shown the XRD results for some of the PbSe / Ag2Se nanostructured TE materials. TE measurements will be performed in the second project year. Figure 2. Sonoelectrochemically synthesized nanoparticles for improving the TE properties of the PbTe matrix. PbSe nanoparticles were synthesized for a doped character of the PbTe or PbSe matrix with different nanoparticles sizes: A) 10 nm diameter B) 20 nm diameter, and C) >30 nm diameter. D) Ag¬2Se nanoparticles of ~ 100 nm diameter. Cold pressing pellet PbSe NPs were mixed with PbTe micron powder material and being pressed into pellets under 350 MPa pressure at room temperature for one hour. The XRD of these pellets made of pure PbTe and the mixture of PbSe/Te with the PbSe NPs (the PbSe NP XRD is shown above) is shown below. Initial thermoelectric characterization revealed that the PbSe NP-doped PbTe TE material showed increased electric conductivity compared to the pure PbTe pellet. We also expect a lowered thermal conductivity in this nanocomposite, which will lead to increased TE figures of merit, ZT. Figure 3. XRD of doped and undoped PbTe matrix. The doped sample shows additional PbSe peaks indicating that the doping is successfully performed. Measurements also indicate improved TE properties. The 30 nm PbSe NPs shown in figure 3 C, has been pressed into pellets with Ag2Se as dopant, figure 3 D, under 420 MPa pressure at room temperature for one hour. The XRD results show that after such high-pressure treatment, the individual peaks are still broad as they should be for nanometer scaled structures. The thermoelectric characterization of such nanostructured samples is currently going on. Figure 4. XRD of a Ag2Se-doped PbSe nanoparticles matrix. The doped nanostructured sample shows additional Ag2Se peaks besides the nanoparticles PbSe diffraction peaks, indicating that the nanoparticle doping was successful. Measurements on these purely nanostructured systems are currently ongoing. In a similar fashion we are currently exploring PbSn and Bi2Te3 doping with the elements Se and Sb as dopants. These experiments will be forthcoming in the following project year.