ACS PRF | ACS

All e-Annual Reports

45702-GB10

Design and Systhesis of Core-Shell OptoElectronic Nanoparticles Based on Oligo(p-phenylene)s

The design of better materials for the active layers of photovoltaic devices is a crucial step toward providing next generation devices that will substantially impact the global energy production cycle. Semiconducting polymers integrated with dendrimers are generating significant interest as exciting new materials that exhibit high fluorescence quantum efficiencies, yet fundamental understanding of the physics of these new materials is needed. The objective of this research is to investigate hybrid systems that link the well-established platform of paraphenylenes with hyperbranched polyglycerols and inorganic semiconductors. This report summarizes progress made this year in three areas: 1) Design and synthesis of hyperbranched polyglycerols; 2) Design and synthesis of oligomeric paraphenylenes with donor side chains of increasing bulkiness; and 3) Advances towards preparation of metal selenides.

Design and synthesis of hyperbranched polyglycerols

Hyperbranched polyglycerols (HPG) were synthesized according to the literature by controlled anionic ring-opening multibranching polymerization of glycidol making use of a partially deprotonated 1, 1, 1 –tris(hydroxylmethyl) propane as an alkoxide initiator.[1] Preliminary studies targeted four materials with a monomer to initiator mole ratio of 100:1, 90:1 50:1 and 66:1 respectively. Only the 100:1 and 50:1 HPGs provided viscous fluids after work up. Characterization by nuclear magnetic resonance (NMR) suggested results similar to those published in literature: 1H NMR spectra in methanol show the four methylene and one methine proton of polyglycerol as a broad peak between 3.279 and 3.908 ppm and hydroxyl protons at 4.972 ppm. 13C/DEPT studies agree with those values reported in the literature. Preliminary DSC results of the 50:1 HPG suggest a glass transition temperature of -5oC. Similar studies will be conducted on the other polymers.

|

Figure 1. Hyperbranched polymers 100:1 and 50:1

Design of oligomeric paraphenylenes with bulky side chains

The objective of this study is to evaluate the kinetics of coupling and corresponding transfer energy of side chain substituted dichloro phenylenes. A series of oligomeric paraphenylenes with side chains of increasing bulkiness (see B1 – B3 in Figure 2) were targeted. The reaction was controlled by either the ratio of monomer to initiator and/or the duration of the reaction. Preliminary studies on commercially available 2-chloro and 3-chloro benzophenone involved nickel (II) chloride coupling in dimethylformamide for 15 minutes, 30 minutes, and 1 hour. It was noted that the reaction solution appeared pink, lavender, and pale green respectively after work up. The DMF was removed under reduced pressures to afford oils as products. Purification and characterization of these materials are underway.

|

Figure2. Schematic showing targeted monomers.

Preliminary modeling studies suggest that the side chain has a direct impact on the co-planarity of the phenyl-phenyl ring system. These investigations are ongoing and will be extended to other model compounds in the series discussed above.

Figure 3. Effect of Side Chain on Coplanarity of Model Paraphenylenes

Advances towards metal selenides

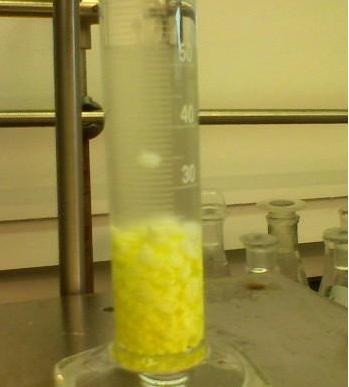

Mo2C and WC nanocrystallite powders have been prepared in the laboratories of Professor Kenneth Roberts at NC A&T. Drawing from this expertise, a wet chemistry experiment was developed by Roberts in Taylor's laboratory this summer to prepare metal carbide sol gels using the Hudson technique [2]. In brief, a aqueous sodium tungstate solution was prepared. A 10% aqueous ammonium polyacrylate solution was used as supplied. The precipitating medium (1-hexanol saturated with hydrochloric acid (HCl)/concentrated HCl) was prepared by shaking hexanol with concentrated HCl, separating the phases, discarding the HCl, and using the HCl-saturated hexanol/HCl as the precipitating agent. A surfactant (0.1% of sodium dodecyl sulfate) was utilized to reduce the surface tension. The polymer/surfactant solution was added dropwise from a separator funnel to a 100-cm3 graduated cylinder. The cylinder was filled with a layer of approximately 40 cm3 of concentrated HCl topped with 50 cm3 of HCl-saturated hexanol. Hydrolysis of the tungstate/polymer solution commenced as soon as the drops contacted the hexanol. The particles fell slowly through the hexanol/HCl and HCl to the bottom of the reaction vessel. After 1 h of standing in the solution, the particles turned from white to yellow and then dark green in the presence of light. The particles were separated from the solvent and washed copiously with deionized water. The particles were dryed at 100 °C overnight. Characterization of the particles is underway.

The Hudson method is novel and has only been used to prepare WC. It should be feasible to tweak the chemistry to make metal nitrides to prepare new carbides (i.e., Mo2C, TiC and InC). New methods will be developed to produce metal selenide nanoparticles.

|

Figure 4. Example WC sol gels prepared by modified Hudson technique.

References

1. Sunder, A.; Hanselmann, R.; Frey, H.; Mulhaupt, R. Macromolecules 1999, 32, 4240-4246.

2. Hudson, M. J. John W. Peckett, J. W.; Harris, ,P. J. Ind. Eng. Chem. Res. 2005, 44, 5575-5578