ACS PRF | ACS

All e-Annual Reports

44857-AC9

Surface Deformation from Particle Impacts in a Liquid Environment

SURFACE DEFORMATIONS FROM PARTICLE IMPACTS IN A LIQUID

Fluid-particle flows encompass a diverse range of industrial and geophysical problems. In some applications, the particles impact the wall or bounding surface causing significant surface deformation. These erosion processes can affect equipment performance, as well as reducing reliability and operation life of piping and machinery.

The current work at Caltech involves a series of experiments of normal particle collisions with a deformable surface. The premise of the work is that by studying individual collisions, we will be able to improve the modeling of collisional interactions and deformation for flows involving many particles. The proposed experiments will involve a range of impact conditions and material properties. The material properties of the particle and the sample allowed us to assume that the particle is rigid and does not deform plastically. The plastic deformations occur only on the samples. All collisions were recorded with a high speed camera; the impact and rebound particle velocities were estimated based on the particle position.

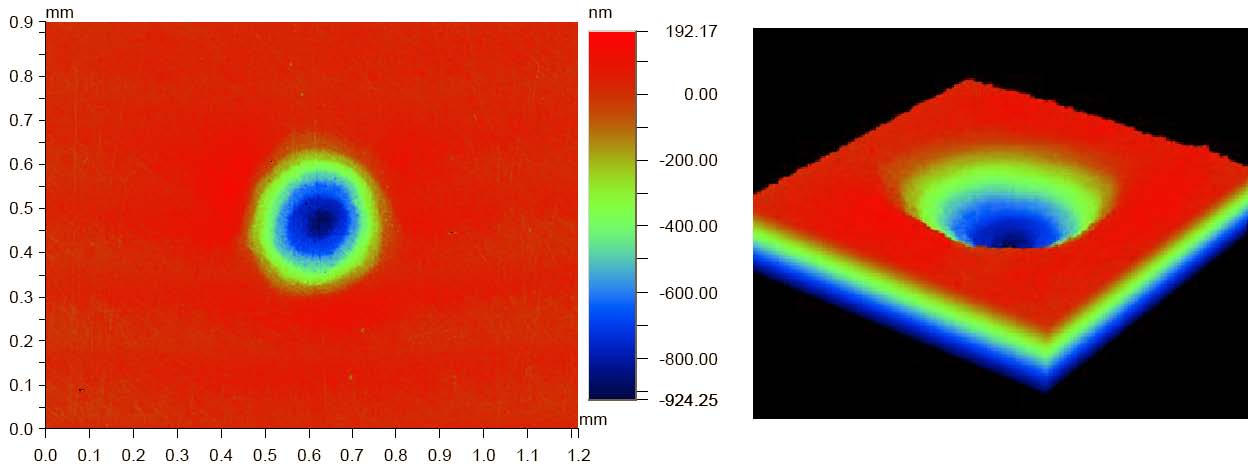

By using a WYKO optical profilometer, we measured the deformation parameters that characterize a typical indentation: crater diameter and indentation depth. Since the deformations are small, the sample surfaces were polished and the resulting surface roughness was at least an order of magnitude less than the smallest indentation. An example of a crater resulting from particle impact is shown in the figure below.

The crater resulting from a 0.013 m diameter steel sphere impacting an aluminum surface at a speed of 0.24 m/sec in a glycerol/water mixture. The resulting crater diameter is 400 μm with a depth of 0.92 μm and a surface roughness of 0.017 μm.

In addition to previous studies of particle-wall collisions under liquid environments, where no permanent deformation was presented, elastic-plastic deformation was added in the total energy budget. We found three different stages where different processes were present.

- At very low Stokes numbers (low impact velocity or a viscous fluid), the collision process is practically elastic, similar to the previous studies. The particle inertia is balanced with the viscous effects, resulting on a very low coefficient of restitution.

- At moderate Stokes numbers (increasing the impact velocity), the samples presented permanent deformations, this regime is called "elastic-plastic". The fluid conditions are still viscous enough so that the coefficient of restitution is low, but monotonically increasing with the Stokes number. Note that the deformation parameters, such as crater diameter and indentation depth, increase with the Stokes number. The surface deformation and the viscous effect are coupled.

- At relatively high Stokes numbers, the coefficient of restitution reaches a maximum (asymptotically) and starts decreasing from there as a function of the Stokes number. The maximum coefficient of restitution is below one and its value varies with the sample material properties.

We have been able to find a regime where energy dissipates in two ways; elastic-plastic deformation and viscous dissipation. For relatively high Stokes numbers, the coefficient of restitution decreases, as do dry collisions. In previous studies we have found that for large Stokes numbers the difference between dry collisions and wet collisions is imperceptible.