ACS PRF | ACS

All e-Annual Reports

43993-AC10

Multiscale Modeling of Hydrogen Embrittlement in Metals

We have recently developed three distinctive QM/MM multiscale approaches that couple quantum mechanical (QM) calculations to classical atomistic simulations (MM) for metals. The first approach deals with the coupling between Kohn-Sham density-functional theory (KS-DFT) and EAM classical atomistic method with the coupling energy calculated classically by EAM. The second approach concerns the coupling between orbital-free density functional theory (OFDFT) and EAM but with the coupling energy calculated quantum mechanically by OFDFT. The third approach is similar to the first one, but with the interaction energy calculated quantum mechanically by OFDFT. Unlike most of most QM/MM approaches, our methods (the last two) allow charge transfer between QM and MM regions. The electrons in QM region not only feel the Kohn-Sham effective potential in QM region, but also feel an additional embedding potential generated by electrons (Hartree, exchange and correlation and kinetic energy contributions) and ions (pseudopotential contribution) in MM region as well. This embedded potential is evaluated rigorously by OFDFT. The first approach has been incorporated into Quasicontinuum (QC) method, which is a multiscale approach that seamlessly combines classical atomistic calculation with finite-element simulations. We have thus achieved one of the goals stated in the proposal, namely, developing concurrent multiscale approaches (QCDFT) that span from electrons to finite-elements for metallic systems. We are currently working to incorporate the second and third coupling approaches into QC method.

We have applied the multiscale methods to study crack propagation in Al in the presence/absence of hydrogen impurities at the crack tip (Fig. 1). We find partial dislocations are nucleated at the crack tip and moved away from the crack tip under stress. These partial dislocations blunt the crack tip and render a ductile fracture in the absence of H impurities. When H impurities are introduced, the fracture toughness is significantly reduced.

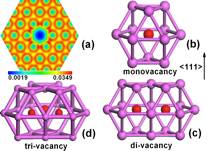

We have also performed multiscale simulations for homogenous nucleation of vacancy clusters in fcc metals (including Al, Cu, Ni, Pd, Ag, Au, Pt and Ir). We computed Gibbs free binding energy of vacancy clusters in Al and carried out thermodynamic analysis of void formation. We introduced a critical nucleus size for void formation and examined the dependence of the critical size on temperature and hydrostatic pressure. We found that while pressures can enhance void formation, tensions tend to inhibit or prohibit void it. We discovered that the "bonding cages" (Fig. 2) play a crucial role in void formation in f.c.c. materials. The formation of the "bonding cages" significantly reduces the propensity of void formation. A simple model is proposed to explain the connection of "bonding cage" and the tendency of void formation for all f.c.c. metals. Finally, we find that the formation of "bonding cage" is closely related to the directionality of the bonding in the metals. We have also studied the strengthening mechanisms in bimetallic Cu/Ni thin layers by using a hybrid approach that links the parametric dislocation dynamics method with ab initio calculations. The hybrid approach is an extension of the Peierls–Nabarro (PN) model to bimaterials, where the dislocation spreading over the interface is explicitly accounted for. The model takes into account all three components of atomic displacements of the dislocation and utilizes the entire generalized stacking fault energy surface (GSFS) to capture the essential features of dislocation core structure. Both coherent and incoherent interfaces are considered and the lattice resistance of dislocation motion is estimated through the ab initio-determined GSFS. The effects of the mismatch in the elastic properties, GSFS and lattice parameters on the spreading of the dislocation onto the interface and the transmission across the interface are studied in detail. The hybrid model shows that the dislocation dissociates into partials in both Cu and Ni, and the dislocation core is squeezed near the interface facilitating the spreading process, and leaving an interfacial ledge. The competition of dislocation spreading and transmission depends on the characteristics of the GSFS of the interface. The strength of the bimaterial can be greatly enhanced by the spreading of the glide dislocation, and also increased by the pre-existence of misfit dislocations. In contrast to other available PN models, dislocation core spreading in the two dissimilar materials and on their common interface must be simultaneously considered because of the significant effects on the transmission stress. Using an ab initio-based parametric dislocation dynamics approach we show that Shockley partials on successive glide planes greatly assist the widening of stacking faults (SF) in Al and Ag. This effect is amplified when all trailing partials are pinned. Subsequent placement of Shockley partials on adjacent planes enhances further the widening of the SF width. In sharp contrast, dislocations with zero net Burgers vector across three successive planes form very compact cores in both Al and Ag, in agreement with recent experiments.