Reports: AC9

47421-AC9 Stability Behavior of Clay/Nanoparticle Suspensions

Overview

The effect of added clay particles on the structure and properties of freeze-dried composites of silica nanoparticles was investigated experimentally. The composites display a porous structure arising from the formation and propagation of ice crystals during freezing (termed freeze casting). The addition of kaolinite clay particles to the dispersion used in synthesizing the composite was found to alter significantly the size and shape of the pores, as well as the mechanical strength of the composite.

Sample Preparation

The samples were produced using kaolinite clay (average plate diameter of 5 microns), silica nanoparticles (Ludox TMA, 22 nm diameter), sodium chloride and de-ionized water. The clay was washed in 1 M NaCl prior to use to create a more uniform surface chemistry on the platelets.

Solutions were produced by adding first preparing an aqueous dispersion of nanoparticles at the desired concentration (typically 3 to 10% volume). Clay platelets were then added at concentrations ranging between 0 and 15% volume, and the dispersion was thoroughly mixed using a vortexer. Finally, 5 M NaCl was added to bring the total salt concentration to a target level (typically between 0.2 and 0.7 M NaCl). The system was again agitated, and then left to gel for four to eight hours.

After gellation, the samples were frozen using either rapid immersion in liquid nitrogen (-196oC) or liquid propane (in a bath of liquid nitrogen). The samples were then exposed to vacuum overnight to sublimate the water. Some samples were also frozen using a commercial freeze-dryer at -35oC. While the freezing method was found to have a substantial impact on the resulting pore structure, this report will focus only on the effect of the added clay.

Results

Tests were performed to determine the effect of the clay additive on the pore structure, surface area, and compressive strength of the freeze-dried composites. The results of these tests are summarized below.

Pore Structure

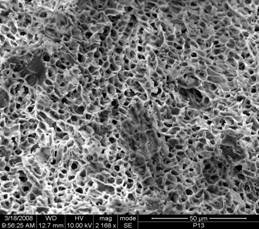

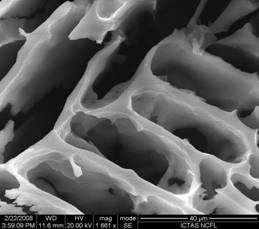

The effect of clay on the resulting pore shape and structure can be clearly seen in the two SEM micrographs below. The sample on the left was produced using 14% vol. clay, 8% vol. silica nanoparticles, and 0.5 M NaCl, while the sample on the right contained the same concentrations of silica nanoparticles and salt but with no clay. Both samples were frozen in liquid nitrogen.

As seen, with no added clay, the resulting pores are much larger (pore sizes over 50 microns) and elongated. By comparison, with the added clay, the pores are much more regular in shape and roughly an order of magnitude smaller. Clearly the clay particles are altering the growth of the ice crystals during the freezing process.

Figure 1. The SEM image on the left was taken on a freeze-dried composited containing 14% vol. clay, 8% vol. silica nanoparticles, and 0.5 M NaCl, while the sample on the right contained the same concentrations of silica nanoparticles and salt but with no clay. Both samples were frozen in liquid nitrogen.

Surface Area

The specific surface area of the freeze-dried materials was measured using BET analysis. A sample containing 9% vol. clay, 8% vol. silica and 0.5 M NaCl was found to have an average surface area of 62±4 m2/g. When the clay concentration was increased to 14% volume, the surface area decreased to 52±2 m2/g. By comparison, the manufacturer-reported surface areas for the clay and silica are 7 m2/g and 140 m2/g respectively, clearly indicating that the majority of the surface area in the composites arises from the silica nanoparticles.

Compressive Strength

The compressive strength of the freeze-dried composites was characterized by measuring the amount of compression versus applied normal load. The effect of the added clay particles on the compressive strength can be seen in the graph below.

Figure 2. The graph plots the degree of compression of a sample versus normal load.

As the concentration of clay increases from 0 to 14% vol. at a constant concentration of the nanoparticles, the resistance of the sample to compression increases. For example, at 1 mm of compression, the load is 0.16, 2.32 and 6.99 N for the 0, 9 and 14% vol. clay samples, respectively.

Current Focus

The current focus of the research is to investigate the properties of ceramics produced from these porous silica composites. These will be produced by sintering the samples at high temperatures (i.e., 1000oC), such that the silica particles fuse together.

Impact

The work so far has allowed us to clearly determine the fundamental mechanism responsible for the formation of the porous material, which had been in question for some time. Now that this question has been answered, we can move forward with characterizing and controlling the properties of the materials, which is critical for developing future applications.

The ACS-PRF support provided support to a post-doctoral

researcher who is interested in an academic career. The researcher recently accepted a position

at the