Reports: AC9

45918-AC9 Modeling the Influence of Flow and Mass Transport during in Situ AFM Measurements of Solution Crystal Growth

Introduction

Crystal growth from the liquid phase, or solution crystal growth, is employed for the production of a vast array of materials, ranging from pharmaceuticals to nonlinear optical crystals. In the petroleum area, the growth of crystalline gas hydrates from liquid hydrocarbon mixtures leads to equipment and pipeline clogging during drilling operations and is an expensive problem for the oil industry. Such issues become more significant in arctic and deep-water drilling processes, where lower temperatures and higher pressures promote hydrate crystal formation. Additionally, there has been recent interest in the production and use of crystalline hydrates for storage and transport of natural gas. A better understanding of solution crystal growth, especially the fundamental factors influencing growth rate, shape, size, purity, and perfection, would benefit these areas.

Toward this goal, atomic force microscopy (AFM) has become the preeminent experimental tool for in situ and real-time measurements of solution crystal growth, enabling the direct imaging of surface terraces, ledges, and kinks. From such measurements, thermodynamic and kinetic properties of the crystal surface can be estimated. Impressive as these techniques may be, however, there are no independent means of determining the measurement conditions. Indeed, mass transport limitations and adverse forces on the tip caused by fluid flow are known artifacts in some AFM experiments.

We aim to quantitatively model the effects of continuum transport processes during experimental measurements of solution crystal growth systems carried out in fluid cell AFM (atomic force microscopy) systems. Our goal is to produce the most detailed attempt yet at a truly quantitative model for such systems. With this model, we aim to analyze conditions under which flow and mass transfer are expected to impact AFM measurements, and suitable strategies to minimize such effects will be addressed. Such work will allow one to "model the measurement," i.e., to employ modeling in conjunction with AFM experiments to obtain accurate interpretations of measurement data.

Approach

Our goal is to construct a faithful continuum-level model of flow and solute transport through an AFM fluid cell in which solution crystal growth is being measured. For the sake of brevity, we do not discuss the details of the mathematical model; it comprises the Navier-Stakes equations for flow, written for an incompressible fluid, coupled with a convection-diffusion equation to represent the solute field.

We employ a Galerkin finite element method with equal-order, piecewise-linear, Lagrangian basis functions over an unstructured mesh of tetrahedral elements. The resulting set of nonlinear, ordinary differential equations is solved either for steady states, with time derivatives set to zero, or integrated in time using implicit methods. In either case, the Newton-Raphson method is applied. The resulting large set of linear equations is solved in parallel. Our initial approach employed an LU solver from the SPOOLES library, which relies upon matrix formulation routines from the PETSc library.

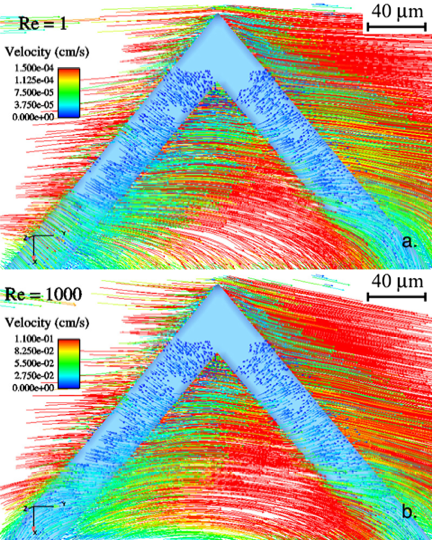

Fig. 1: Preliminary studies of steady-state flow in an in situ AFM experiment of solution crystal growth. Flow vectors are plotted along the sample-scanning side of the AFM cantilever (the normal to the scanning surface points out of the page) at different Reynolds numbers: (a) Re = 1 and (b) Re = 1000.

Project Results

Initial results for computation of flow fields in the AFM system were quite successful. For example, fluid flows near the tip of the cantilever are shown by vectors in Figure 1. Comparing the two flows, the magnitude of the velocities scales with the ratio of the Reynolds numbers, as expected. However, there is a significant change in the spatial form of the flow fields. This effect is due to the responses of the flows to the geometry of the system, as was discussed above. Notably, the predominant direction of the flow near the extremity of the cantilever is shifted substantially; note the downward slant of the Re =1000 flow. One would expect that the measurement conditions at the AFM tip would differ for these two cases.

The next goal of this research project was to implement a more efficient solver employing GMRES with preconditioning in order to effectively compute solutions with far higher levels of discretization than employed before, thus allowing us to investigate mass transfer with higher levels of accuracy. With these higher levels of solution accuracy, we had hoped to investigate many different conditions that would describe a wide variety of crystal growth systems (being measured in an AFM system).

While initial results were encouraging, providing material that was discussed in several scientific presentations in seminars and at conferences (listed below), our attempts to improve the underlying computational algorithms proved to be unsuccessful during the time frame of this project. We are still assessing the failure of our approach; however, we suspect that our preconditioning methods were inadequate to allow for solution convergence using GMRES for the cases of interest to us. Since all funding and associated effort have been expended in the ACS-PRF grant, we are now actively pursuing additional funding from other sources, notably the National Science Foundation. One positive outcome of this grant was the support of a female graduate student, Ms. Wei Wang, during the first two years of here Ph.D. studies.

Presentations discussing results

J.J. Derby, "Modeling the Interaction of Multiple Scales in Melt and Solution Crystal Growth," Department of Chemical Engineering, Texas Tech University, Lubbock, TX, March 9, 2007.

J.J. Derby, "Modeling the Interaction of Multiple Scales in Solution Crystal Growth," Computational Materials Engineering, Center for Computational Engineering Science (CCES), Institute of Minerals Engineering (GHI), RWTH Aachen, Germany, May 8, 2007.

J.J. Derby, "Large-scale numerical modeling of melt and solution crystal growth," 13th International Summer School on Crystal Growth (ISSCG-13), Park City, UT, August 7, 2007.

W. Wang, D. Gasperino, A. Yeckel, and J.J. Derby, "Analysis of Fluid Flow and Mass Transport during AFM Measurements of Solution Crystal Growth," (Poster presentation by W. Wang), ACCGE/West-21, the 21st Conference on Crystal Growth and Epitaxy - West, Fallen Leaf Lake, CA, June 8-11, 2008.