Reports: AC10

45215-AC10 Synthesis and Polymorphic Control for Visible Light Active TiO2 Nanoparticles

Kathleen Richardson, Clemson University

Research Activities

During the 3rd year of this project, research was focused on deactivation and regeneration of visible light active predominantly brookite titania nanoparticles.

The SACS technique, with N-methylpyrrolidone (NMP) as the

solvent, (U.S. Patent pending) developed by our research group has been used as

a post-synthesis treatment of WACS process [1-4].

The TiO2 powders were calcined in air at 200oC for 2

hours.

Characterizations

All samples were characterized by x-ray

diffraction (XRD), N2 physisorption, UV-Vis absorption

spectrophotometry, FT-IR, TGA, XPS, and TEM

The deactivation of polymorphic brookite titania was

evaluated by observing the photocatalytic degradation of MO under either UV

with wavelength of 365 nm, or VL irradiation of 560-612 nm. The experimental MO test and the calculated

MO degradation percent value, D, were obtained by the procedure found in the literatures [1-5].

Titania samples were

reused for four reaction cycle runs without any intermittent treatments in a

fresh MO solution. Sample IDs of used

TiO2 samples are composed of the fresh TiO2 sample ID, UV

or VL irradiation or dark, and # of cycle runs.

For example, the NMP-200 sample after the first run of MO degradation

under VL irradiation was called NMP-200-VL#1.

After the first reaction cycle,

the used sample was regenerated by several possible procedures, i.e., solvent washing

or recalcination at various temperatures.

The regeneration of the

catalyst was investigated by reusing 0.1 grams of a regenerated titania sample

in the second reaction cycle under the same condition as the first one.

Results

The physical properties of fresh

and used TiO2 samples and the reference VLP7000 are given in

Table 1. The reference Kronos

samples (VLP7000) are 100% anatase phase and have similar crystallite size to

our prepared titania. The surface areas

of as-prepared

titania samples are

approximately 1.8 times smaller than that of Kronos sample.

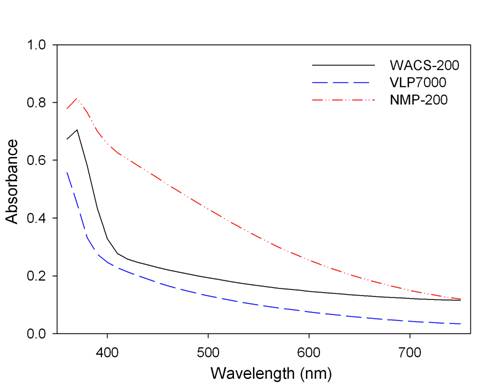

UV/Vis spectra of titania samples are given in Figure 1. The NMP-200 sample exhibited a shift of the absorption shoulders to the VL

region, compared to WACS-200 and VLP7000.

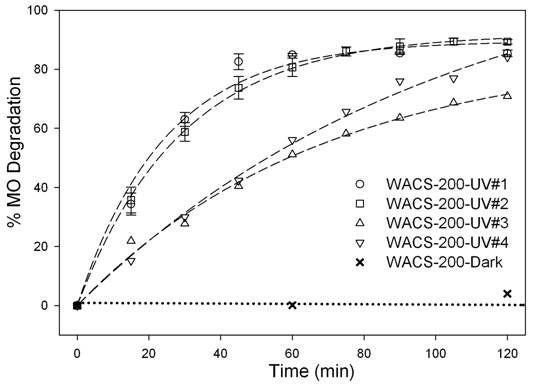

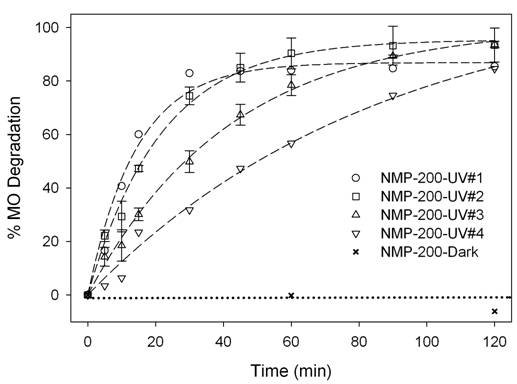

The stabilities of WACS-200

and NMP-200, determined by the MO degradation under UV irradiation, are

given in Figures 2(a) and 2(b), respectively.

MO with titania samples stirred in the dark was not degraded. The MO degradation by NMP-200 was 10 minutes

faster than by WACS-200, as expected, because of fewer lattice hydroxyls in NMP-200

sample [2, 3]. Both samples did not deactivate after the

first reaction cycle. After the second

cycle, however, PCA of both samples gradually decreased with the increase in

the testing time.

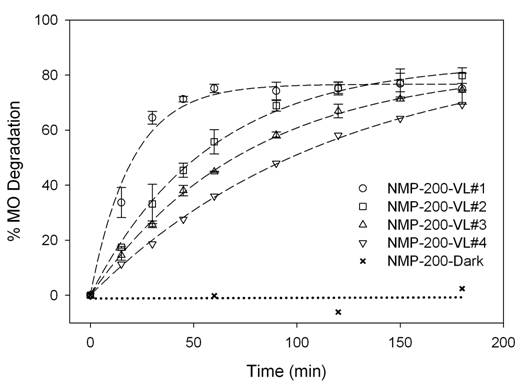

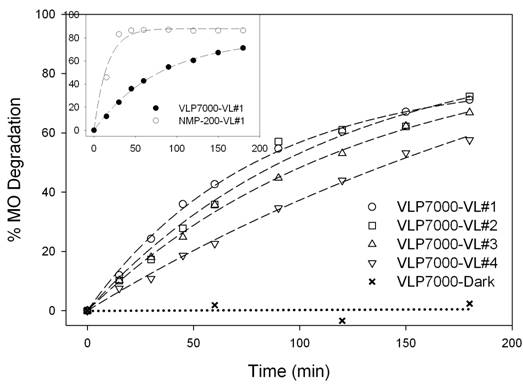

The deactivation of NMP-200 and VLP7000, evaluated by MO

degradation under VL irradiation, is reported in Figures 2(c) and 2(d),

respectively. The MO degradation rate by

NMP-200 exhibited approximately 3.3 times higher than that of VLP7000, as shown

in the inset of Figure 2(d), despite the much lower surface area of NMP-200 than that of VLP7000. This VLA superiority of NMP-200 must be due to the

presence of brookite phase with the significant proportion of anatase, as

reported in our previous paper [4], compared to 100% anatase

for VLP7000. It is also supported

by UV/Vis spectra in Figure 2(a) that NMP-200 can absorb more VL than

VLP7000. Nonetheless, both NMP-200 and

VLP7000 gradually deactivated with the increasing number of reaction cycles. The catalyst deactivation is possibly

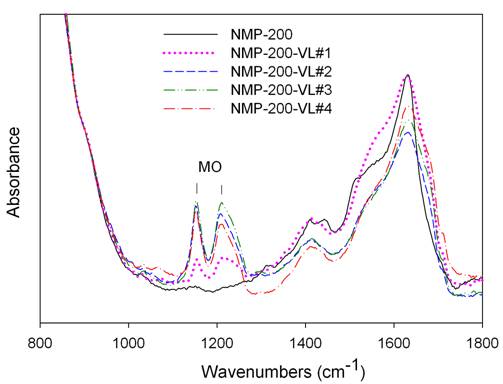

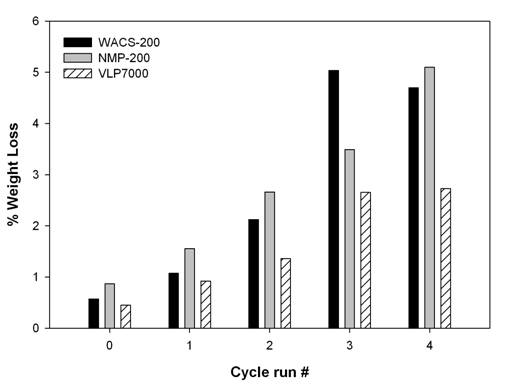

attributed to the deposition of the decomposed MO. The carbonaceous deposit, called coke [6-8],

was examined by FT-IR (Figures 3), TGA (Figure 4), and XPS.

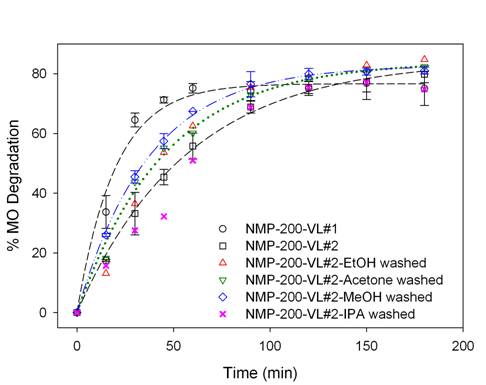

To study the catalyst

regeneration by solvent washing, NMP-200-VL#1 was washed with various solvents,

i.e., methanol (MeOH), ethanol (EtOH), isopropanol (IPA), or acetone. Figure 5 presents the regeneration of

NMP-200-VL#1 by washing evaluated by the MO degradation under VL

irradiation. Among the washing

procedures of the used samples, MeOH washing was shown to be the most effective

up to ~80% recovery of the fresh sample.

Table 1:

Sample ID

Crystallite size (nm)a

BET surface area (m²/g)b

Pore volume (cm³/g)b

Pore size average (Å)b

Anatase

Brookite

Rutile

WACS-200

5

9

11

169

0.1

25

WACS-200-UV#1

7

10

10

177

0.1

27

NMP-200

7

8

13

157

0.1

24

NMP-200-VL#1

7

9

11

220

0.1

25

NMP-200-VL#2

5

8

16

202

0.1

26

NMP-200-VL#3

6

7

12

175

0.1

27

NMP-200-VL#4

7

7

10

185

0.1

27

NMP-200-UV#1

6

7

12

206

0.1

25

VLP7000

7

-

-

290

0.4

56

VLP7000-VL#1

9

-

-

287

0.4

59

a Calculated from

XRD data using the Scherrer equation. Error of measurement = ±5%.

b Using N2

physisorption at -196°C. Error of measurement = ±10%.

Figure 1

Figure 2(a)

Figure 2(b)

Figure 2(c)

Figure 2(d)

Figure 3

Figure 4

Figure 5

Conclusions

The deactivation of WACS-200 and NMP-200 was evaluated by the

degradation of MO under either UV or VL irradiation for 4 reaction cycle runs

without intermittent treatments, and then compared to VLP7000. NMP-200 was found to be much more VLA than

VLP7000, although NMP-200 has 1.8 times smaller BET surface area than

VLP7000. This VLA superiority of NMP-200 is due to mixed

brookite and anatase titania phases, compared to pure anatase phase of VLP7000. However, PCA under VL of both NMP-200 and

VLP7000 gradually decreased with increasing the number of reaction cycles. The cause of the deactivation of the titania

samples in this study was identified as the deposition of the decomposed MO or

the carbonaceous deposit, called coke.

The regeneration of the used NMP-200 samples was also

investigated. Among the solvent washing

procedures for used NMP-200, MeOH washing was shown to be the most effective

with up to ~80% of the PCA recovery.