Reports: G7

47740-G7 Solvent-Temperature Superposition Rules for Predicting the Rheology of Wormlike Micellar Fluids

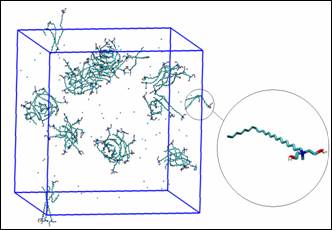

The goal of this project is to use a combination of atomistic and mesoscale simulations to decipher the relationship between the unique rheological properties of wormlike micelles[1] and the molecular scale structure and interactions in these systems. A description of these modeling efforts is presented below:

(A) Atomistic simulation:

The structure and dynamics in the micellar system consisting of EHAC [erucyl bis(hydroxyethyl) methylammonium chloride] surfactant molecule was studied using atomistic simulations. The molecular dynamics (MD) simulations were carried out using the GROMACS package.[2] The simulated system consisted of 100 EHAC molecules and 54773 water molecules, with 100 chloride ions added to maintain charge neutrality. The initial structure was energy minimized using the steepest descent method, followed by a constant NPT (number of particles, pressure and temperature) MD simulation run for 40 ns.

Fig. 1. Configuration of the EHAC molecules after

40 ns of MD NPT simulation (water molecules

have been removed for clarity). Inset

shows an EHAC molecule.

As seen from Fig. 1, the EHAC

molecules were observed to form aggregates of different sizes. The Gromos clustering algorithm[3] in

GROMACS was utilized to quantify this aggregation behavior of the EHAC

molecules in solution, the results are shown in Fig. 2.

(a) (b)

Fig. 2: Aggregation of EHAC molecules as shown by (a)

Time dependence of the number of clusters and (b) Time dependence of the average

number of molecules per cluster.

(B) Mesoscale simulation:

In order to capture the

rheological properties of the wormlike micelles as measured in experiments, we

need to simulate the systems on much longer length and time scales than

possible using atomistic simulations.

In this project, we have decided

to use the multi-particle collision dynamics (MPCD) method[4] for this purpose. The coarse grained models used in these

mesoscale simulations will be developed from the atomistic simulations as

described above. As a first step, we are

currently developing a simulation code for implementing the MPCD method. A brief description of this simulation method

and the results from our calculations are presented below.

MPCD Method:

In the MPCD method, the solvent

is described as a collection of N

point particles. These particles are

assumed to interact at discrete time intervals by collision events and are

assumed to undergo free streaming motion in between these collisions. The dynamics of the solvent particles is thus

implemented in two steps:[5]

(1) Streaming step:

where

Fig. 3: Schematic illustrating the partitioning of the box into cells

containing the solvent particles and one bead-spring polymer chain in MPCD

simulation. Inset shows the rotation of

the relative velocity of every solvent particle in a MPCD cell.

(2) Collision step: The

particles are first sorted into cells (see Fig. 3). The relative velocity (with respect to the center

of mass velocity in that cell) of each of the particles in a cell is then

rotated by a chosen angle:

where

A hybrid approach is used for simulating

the dynamics of a solution containing a solute that is dissolved in the mesoscopic

solvent as described above. In this

case, the free streaming step is replaced by usual MD simulation for the

solvent and solute particles to account for the specific interactions between

the solute and the solvent whereas the solvent-solvent interactions are captured

via the collision step as described above.

The initial simulation system studied

contained 326769 solvent particles in a box of dimensions 32x32x32 and at a temperature

of 1/3. The angle of rotation was

π/2 for all cells. Furthermore, the

system contained one colloidal molecule (radius = 3σ, mass = 250) that

interacted with the solvent molecules via the Lennard-Jones (LJ) potential (all

values are in reduced LJ units). In the

simulation, 50 MD steps were carried out between successive collision steps and

the system was equilibrated for 20,000 MD steps. In order to validate our code, the normalized

velocity autocorrelation function (VACF) of the solute particle was calculated.

Fig. 4: Normalized VACF of the colloidal particle

averaged over 10 blocks

The VACF shown in Fig. 4

is qualitatively similar with that in the literature but differs from it

quantitatively.[7] Currently this issue is being

investigated. Once this issue is resolved

and the code is validated, a similar test will be performed for the MPCD code

for a polymer solution; the validated code will then be used for studying the

rheology of the wormlike micellar systems.

Impact of the

research on the PI and the graduate student

The PI (Khare) has a strong track

record of atomistic level simulations of polymeric systems as well as nanoscale

transport phenomena. The ongoing work on

this project in the area of MPCD simulations will allow the PI to expand his

research portfolio to mesoscopic modeling techniques. The graduate student (Govind Hegde) working

on this project is receiving multidisciplinary training in the areas of

chemical engineering, mesoscale and atomistic simulation methods and rheology

of complex fluids.

References:

[1]

Siriwatwechakul,W.; LaFleur, T.; Prud'homme, R.K.; Sullivan, P.; Langmuir, 20, 8970-8974 (2004).

[2] 2. Hess,

B.; Kutzner, C.; van der Spoel, D.; Lindahl, E.; J. Chem. Theory Comput.

4, 435-447, (2008).

[3] Daura, X.; Gademann, K.; Jaun, B.; Seebach, D.; van

Gunsteren, W. F.; Mark, A. E.; Angew. Chem. Int. Ed. 38, 236-240, (1999).

[4] Kapral, R.; Adv. Chem. Phys.; 140, 89 (2008).

[5] Malevanets, A.; Kapral, R.; J. Chem. Phys. 110,

17, 8605-8613, (1999).

[6] Ihle, T.; Kroll, D. M.; Phys. Rev. E., 63,

020201, (2001).

[7] Malevanets, A.; Kapral, R.; J. Chem. Phys. 112,

17, 7260-7269 (2000).

![]() and

and

![]() denote the position and velocity of particle i at time t.

denote the position and velocity of particle i at time t.

![]() is the center of mass

velocity and

is the center of mass

velocity and

![]() is the rotation matrix. The rotation is done by a fixed angle α

about a randomly oriented rotation axis.

Same rotation is applied to all particles in one cell but the rotations

in different cells are independent of each other. To ensure Galilean invariance for the

simulation, a random lattice shift for the cells is applied before each

collision step, to change the neighborhood of the particles.[6]

is the rotation matrix. The rotation is done by a fixed angle α

about a randomly oriented rotation axis.

Same rotation is applied to all particles in one cell but the rotations

in different cells are independent of each other. To ensure Galilean invariance for the

simulation, a random lattice shift for the cells is applied before each

collision step, to change the neighborhood of the particles.[6]